Applying the Principles of the Work Zone Rule to Design-Build Projects, Two Case Studies

4. Colorado US 285 Design-Build Project

This section presents an overview of the US 285 project and observations and findings from the case study. It identifies successes, issues, and challenges when applying the Rule during the project development and implementation phases.

Background and Specifications

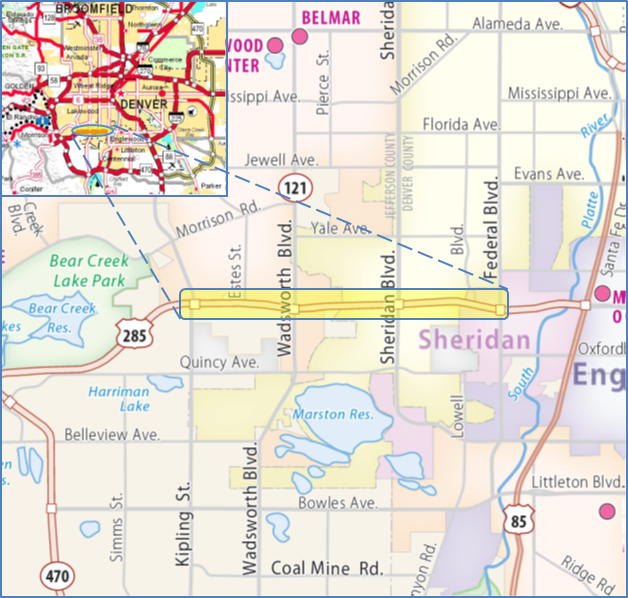

The US 285 Design-Build Project is a $40 million safety and mobility project on US 285 (Hampden Avenue) in the southwestern part of the Denver Metropolitan area. The project area covers the jurisdictions of the City and County of Denver, the City of Sheridan, the City of Lakewood, and unincorporated Jefferson County. Figure 4-1 shows the project location. The project covers four miles of a mostly four-lane limited access facility that includes one signal controlled intersection. The primary elements of the project are reconstruction and/or resurfacing of the highway, replacement and rehabilitation of bridges, and safety and drainage improvements.

The original scope of the $40 million project included:

- Reconstruction of US 285/Hampden Avenue from Federal Boulevard to Wadsworth Boulevard.

- Replacement of three bridges at Wadsworth Boulevard, Pierce Street, and Federal Boulevard.

- Rehabilitation of the bridge decks at Sheridan Boulevard, Estes Street, Raleigh Street, and Bear Creek.

- Reconstruction of the Wadsworth Boulevard Interchange including the addition of a third lane on Wadsworth Boulevard under US 285.

The US 285 Design-Build Project addressed several needs. The project replaced three structurally deficient bridges and reconstructed a four-mile portion of US 285 that was in poor condition. The project also includes the rehabilitation of four bridges, the reconstruction of one interchange, improvement in drainage and water quality, and the addition of a third lane to an arterial street under the corridor. In addition, Knox/Lowell, an at-grade intersection within this part of the corridor, will undergo a slight geometry change and get additional turn lanes in order to improve safety.

This project began as a $10 million design-bid-build bridge replacement project. Then additional elements were incorporated and the scope exploded. CDOT developed a new scope for the US 285 project and released the RFP as part of a "Modified Design-Build" (MDB) project. All the bids CDOT received for the MDB RFP were much higher than estimated, and none of the bids were accepted.

CDOT again put out an RFP for the project, but this time it would be a value-based design-build. There are several references to the Rule in the RFP, and there is material that is based on seven of the eight key Rule aspects mentioned earlier. CDOT made safety, quality, and mobility a priority, and awarded a significant amount of points for those portions of the proposals. CDOT's RFP included value-based selection safety criteria. CDOT thought the value based selection criteria were essential to getting proposers to maximize safety.

Figure 4-1. US 285 Design-Build Project Location

(Source: CDOT and URS Group, Inc.)

When the project was awarded, it had become a $40 million reconstruction, funded using Federal, State, and Municipal money for different elements of the project. According to CDOT, the winning proposal included superior safety elements to any of the other proposers (one example is the use of positive protection as opposed to cones and barrels). The winning proposer and one other proposer had good quality management and were close on many elements, but the winning proposer figured out how to use both concrete and asphalt to stretch the resources that got them an extra mile of reconstruction to Kipling Street. The other proposers bid all concrete on the job which did not allow for the extra mile of pavement.

Some of the value-added elements that the design-builder worked into their scope included:

- An additional mile of road reconstruction from Wadsworth Boulevard to Kipling Street.

- Wider shoulders from Federal Boulevard to Wadsworth Boulevard; this is a safety and mobility enhancement.

- The use of clear-span bridges which minimizes construction impacts; this is also a safety enhancement, removing bridge piers and improving sight lines.

- The use of positive protection (pre-cast portable barrier) in lieu of barrels and cones.

- Operational improvements at the Knox/Lowell intersection.

- Improved pedestrian facilities on the Federal Boulevard and Pierce Street underpasses.

CDOT used the design-build delivery method because they felt it was the best way to leverage staff resources. They did not have enough designers (50% of the project manager's spots were unfilled), and realized that design-build was a good way to get the project completed faster with their limited staff.

The project was planned for construction in three phases over a 19 month period beginning January 2010. Construction began in the median, pushing traffic to the outside through the corridor. Then traffic was shifted to the outside and Phases 2 and 3 used the new pavement in the median while the north and then south sides of the corridor were constructed. Construction was completed in the Fall of 2011, a few months later than expected, partially due to unexpected stormwater and environmental issues.

The following paragraphs summarize the different plans that were created as part of the project, identify some characteristics that were part of the project coordination, and highlight some of the quality, safety, and mobility related accomplishments of the project.

Project Specific Documentation and Planning

- Quality Management Plan (QMP)

The RFP required that a Quality Management Plan be completed and accepted prior to the first notice to proceed (NTP1). Both CDOT and the Contractor felt that it was valuable to have the QMP in place prior to the design phase. However, there were concerns that this delayed the start of design, and perhaps certain elements of the QMP could be accepted in order to avoid time lost while beginning design.

The QMP consisted of the Quality Assurance (QA) process which includes a list of questions that guide the assessment of TCP development. The QA process is in place to also confirm that complete construction phasing and traffic control plans are included in the correct roadway plans, and that the plans have been prepared by a certified Traffic Control Supervisor and reviewed by the correct personnel. The Quality Control (QC) element of the QMP verifies that the correct Method of Handling Traffic (MHT) and TCP plans are being implemented in the field.

- Public Information Plan (PIP)

The PIP identifies goals and strategies used to ensure honest and effective two-way communication between CDOT and the design-build team, and all stakeholders including the public. It was very valuable to the project to have an effective public information (PI) team. This proved to be integral in maintaining safe and high quality construction, as up-to-date information on staging, work zone conditions and upcoming closures could be provided to the public, law enforcement, emergency responders, and other stakeholders. For the PI portion of the project, the Contractor used a subcontractor that had significant experience from T-REX, Colorado's first major design-build project, a $2 billion multimodal effort in the early 2000s.

- Incident Management Plan (IMP)

One of the technical requirements of the RFP was that an IMP was developed as a companion to the TMP in compliance with CDOT's Incident Management Plan guidelines. The IMP include many components such as a PIP, incident detection and response, how to inform motorists and emergency services of incidents, and the use of Courtesy Patrol among others. The IMP was completed during the initial design phase prior to NTP2.

Project Coordination

- Partnering and coordination were strengths of this project. A task force was created for each specialty (traffic, drainage, structures, environmental) that included CDOT and contractor staff. The task forces held weekly meetings that helped assess and resolve issues early. For example, any issues or complaints received that related to traffic were discussed and evaluated at a weekly Wednesday meeting.

- Co-location was identified as an element of the project that led to strengthened communication and partnering. Because this was a smaller design-build project, the design-build team decided that it did not make sense to co-locate all the project staff. The project required co-location of the core partners, from the owner to construction to quality assurance. Management and construction personnel were co-located, while the designers were located at their offices, not far from the project office. Frequent design coordination meetings substituted for that element of co-location. The Contractor indicated that they would have liked to get design subconsultants some space in the designer's office to improve communication, but it was not economical.

Project Accomplishments

- Quality - The fast-paced nature of design-build projects, and the short time between design of plans for a certain segment, review of those plans, and construction of those plans, has the potential to make document control difficult. A unique method of document control was implemented successfully on this project. All draft plan sheets were printed on white paper, while the Released for Construction (RFC) sets were printed on yellow paper (or printed on white with the word "YELLOW" clearly displayed if yellow paper was unavailable). This reduced potential errors and assured that construction crews were working with the correct and most up-to-date plan set.

- Safety - Safety was the #1 priority for this project and the Contractor made that clear by instilling an ethic of safety. Every morning in the field began with a tail gate talk and then group calisthenics while the equipment was warming up. The Contractor included many safety related elements as value-added components of its proposal that were not required in the RFP. These included the use of positive protection, 12 foot inside shoulders for over half of the project where 8 foot shoulders were required, maintaining two extra lanes through the at-grade intersection during construction, the use of clear-span bridges to maximize visibility and safety (see Figures 4-2 and 4-3), and additional pedestrian facilities. With a design-build contract, the owner can include value-based criteria in the proposal scoring that give credit for work zone safety and mobility elements. This mechanism is not part of a design-bid-build type of contract that is awarded based on low bid.

Figure 4-2. US 285 Bridge over Wadsworth Boulevard before Construction

(Source: CDOT)

Figure 4-3. Schematic of the new Clear Span Bridge over Wadsworth Boulevard

(Source: CDOT)

- Mobility - The RFP required that 2 lanes remain open in each direction during peak hours, but allowed nighttime and weekend closures. Single lane closures were permitted during weekdays in off-peak times. The project team used variable message signs, a telephone hotline, a project website, and frequent emails to registered users to inform the public of upcoming lane closures.

Application of the Work Zone Safety and Mobility Rule

This section examines each of the eight key Rule aspects identified earlier, and discusses successes and challenges in applying each aspect to the US 285 project.

Key Aspect #1 - Work Zone Assessment and Management Procedures

This aspect encourages States to develop and implement systematic procedures to assess work zone impacts in project development and manage safety and mobility during project implementation.

Successes

- In the Instructions to Proposers portion of the RFP, Section 1.5, CDOT stated that the four project goals were safety, quality, managing mobility impacts, and maximizing the scope within the budget. The evaluation structure allocated 35 percent of the points to safety, mobility, and quality. The result of this emphasis was that the Contractor made safety a top priority throughout the project. Examples of their efforts to manage safety and mobility include:

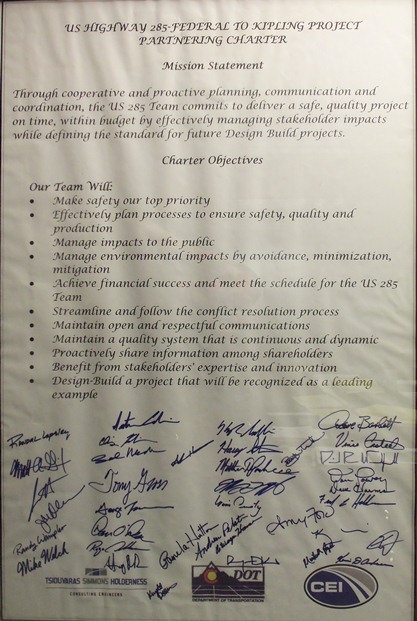

- The Project Partnering Charter (See Figure 4-4)

- Reducing the duration of lane/ramp closures and the overall project schedule

- A safety orientation program for all personnel involved in the project and anyone entering the workspace

- The use of positive protection (pre-cast portable barrier) in lieu of barrels and cones.

Figure 4-4. US 285 Project Partnering Charter

(Source: URS Group, Inc.)

- As part of developing its lane closure strategy for each region, CDOT analyzes its major corridors to determine when lanes can be closed and the resulting impacts to traffic will be acceptable. CDOT relied on that analysis and did not conduct special modeling before letting this project. In the RFP, Section 16 on MOT, CDOT specified that lane closures had to be in accordance with the Region 6 lane closure strategy. Any time the Contractor wanted an MOT variance from contract requirements, the Contractor was required to analyze the traffic impacts and submit a Variance Request. The analysis was based on volumes and looked at expected queues, generally using Synchro for intersections or using peak hour volume-to-capacity analysis for effects on the mainline from strategies like reduced speed limits. In cases where a reduced speed limit was requested by the Contractor, they could perform a simpler volume-capacity analysis with peak hour volumes to assess traffic impacts. One example of the design-build team managing safety and mobility during project implementation is when the designer collected traffic volume data and used the results of capacity analysis for staging decisions in a maintenance of traffic (MOT) variance situation. They modeled traffic to assess queues at the Knox/Lowell and Wadsworth Boulevard intersections. Results from the modeling analysis were used to determine the best geometry and signal timing to maximize the operation of these signalized intersections that had previously experienced excessive delay and long queues.

- By gaining a better understanding of the traffic mix, the Contractor was able to factor that into temporary pavement design, reducing cost (or maximizing value) of the project. Temporary pavement was used for staging and traffic control purposes, often to transition roadway lanes from existing pavement which had yet to be removed onto the new constructed roadway surface. Through research the design-build team identified that this corridor had a lower percentage of commercial vehicles than most facilities of this type. The design requirements for temporary pavement were originally based on characteristics regarding expected wear from commercial vehicles. The new information led to modified design requirements for temporary pavement and resulted in cost savings due to less material being used.

Issues and Challenges

- Development of the QMP was both a challenge and an example of how teamwork and partnering overcame the challenge. The Contractor had a difficult time with developing the QMP as required in the RFP due to the magnitude and complexity. With guidance from CDOT, the Contractor and CDOT worked closely to overcome this challenge by exchanging ideas and identifying CDOT's desired concept for this element of the project. CDOT and the Contractor demonstrated a strong project partnership and effective coordination, facilitated by it being a design-build project and both partners having strong desires to establish a solid QMP to ensure project success.

Key Aspect #2 - Work Zone Data Collection and Analysis

At the project level, States are required to use field observations, available work zone crash data, and operational information to manage work zone impacts for specific projects. At the agency level, States are required to continually pursue improvement of work zone safety and mobility by analyzing work zone crash and operational data from multiple projects to improve State processes and procedures over time.

Successes

Because this case study is oriented to one particular project, this element looks at the project level of this key aspect. The US 285 Project incorporated many data collection methods, by both the Agency and the Contractor. Some of the ways key aspect #2 was applied to the project include:

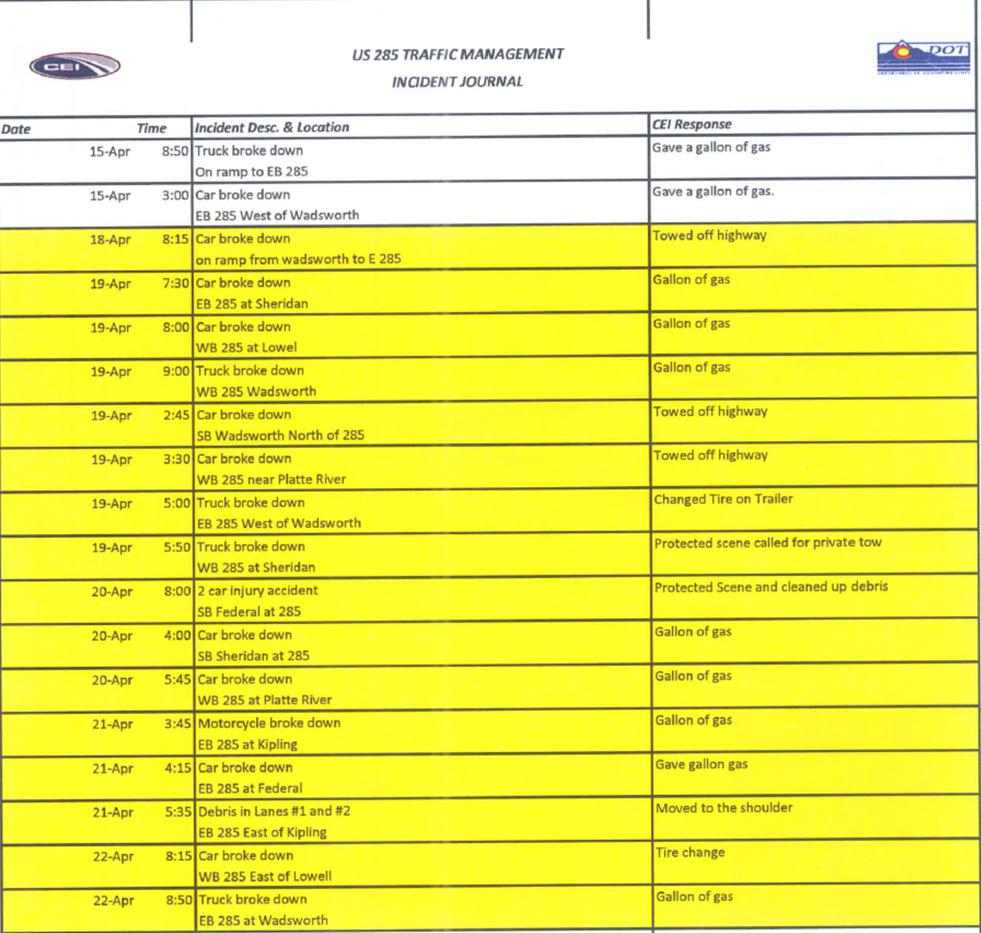

- The Contractor maintained a Traffic Management Incident Journal. This journal recorded any time the courtesy patrol (further described in Aspect #5) responded to an incident, identified the location and type of incident, and how the patrol assisted the motorist or situation. Such assistance included changing a tire, securing a crash scene, or removing debris from the road. A sample of the US 285 Traffic Management Incident Journal is illustrated in Figure 4-5.

Figure 4-5. US 285 Traffic Management Incident Journal

(Source: CDOT)

- One instance where data collection and analysis improved safety and mobility during the project was during demolition of the Wadsworth Bridge. Wadsworth Blvd. had to be closed for two different time periods. The first time, there were severe backups and extensive delay. Because of feedback and observations (data collection) made by the Contractor, the signal timing was adjusted for the second overnight closure. This resulted in less delay and better operation of the intersection.

Issues and Challenges

One challenge for this project was the lack of existing intelligent transportation systems (ITS) such as cameras, VMS and vehicle detection on the corridor that could be used to monitor work zone traffic conditions. Occasionally, a CDOT staff member performed travel time runs by driving the corridor. However, the information was seldom recorded and it was not distributed to other team members. It could be beneficial if a travel time data collection program is part of the contract requirements, and such information could be valuable to facilitate monitoring and management of work zone mobility performance.

Due to resource limitations, the incident data from the Traffic Management Incident Journal were not used to identify potential causes and remedies for the situations, nor were they used for other safety or operational related analyses. Data collected in the Incident Journal could have been used for safety and operational analyses to assist with improving traffic control and management techniques for this as well as future projects, if it was specified as a requirement in the RFP.

CDOT and the Contractor had a difficult time tracking all of the incidents in the work zone. They stated that several times the only way they knew a crash occurred overnight was by finding barriers that had moved or had evidence of a crash. One of the likely causes of challenging communications regarding crashes in the work zone was that the project was under the jurisdiction of five different law enforcement agencies.

Key Aspect #3 - Training

States shall require that personnel involved in the development, design, implementation, operation, inspection and enforcement of work zone related transportation management and traffic control be trained, appropriate to the job decisions each individual is required to make.

Training is an aspect of the Rule that should not differ significantly between design-build and design-bid-build projects. However, since the Contractor may be directly carrying out some responsibilities that it may not typically perform for design-bid-build projects, there may be some additional training needs.

Successes

Some of the successes of this project, according to both CDOT and the Contractor, were the quality control, emphasis on safety, and coordination. Shortly after the contracting agreement was completed, the Contractor created a "Partnering Charter" (Figure 4-4) that was signed by all project staff from the Designer and Contractor (design-build team) and CDOT personnel. The first two objectives listed on the charter were: to make safety their top priority; and effectively plan processes to ensure safety, quality, and production.

The Contractor took the initiative to introduce a two-hour orientation for anyone involved in the project, and anyone who will be in the work area. This orientation, which was not required in the RFP, included environmental, safety, quality, and scope related elements, with a major emphasis on work zone safety. The safety training portion of this orientation included:

- Basic personal protective equipment,

- Work zone safety,

- Working at night,

- Fall protection,

- Demolition,

- Trenches and excavation, and

- Safety tools.

Issues and Challenges

The RFP identified broad training needs in the Quality Management section (Book 2, Section 3), but did not provide detailed requirements. Both CDOT and the Contractor felt that some of the Traffic Control Supervisors (TCS) were not as informed as others. For example, CDOT staff felt that some of the overnight TCS did not have the information and tools they needed to do their job as effectively. This does not necessarily mean that they were not trained appropriately, but that there may have been a disconnect somewhere.

Key Aspect #4 - Process Review

States shall perform a process review at least every two years. Appropriate personnel who represent the project development stages and the different offices within the State and the FHWA should participate. While this aspect pertains to the agency level, it involves receiving data and feedback from staff on individual projects and doing reviews of a sample of projects.

Contractors will typically have a limited role in an Agency's process review, so the process review is an aspect of the Rule that should not differ significantly between design-build and design-bid-build projects. The US 285 Design-Build Project was not part of a process review by CDOT during the development of this case study document. However, several different methods of review and audit have been part of the project internally. CDOT performed quarterly internal quality audits on the US 285 Project. The audits dealt with design quality initially and moved to quality inspection on construction and field work. Other forms of internal review were conducted through the regular project management and safety meetings where items and issues related to schedule, QA, traffic control and ongoing safety were reviewed and discussed.

Issues and Challenges

No issues were identified regarding the implementation of this aspect.

Key Aspect #5 - Transportation Management Plan

States are required to develop and implement a TMP for all Federal-aid projects in consultation with appropriate stakeholders.

Successes

One success of this project was a requirement in the RFP that a task force be established to assure proper coordination with affected agencies, and to make sure the TMP is in conformance with the requirements of the RFP. This work early on built trust between the task force personnel, and laid the groundwork for a positive working relationship. Another benefit of the task force was to make sure that all stakeholders were being included and considered in the creation of the TMP and IMP. Because this project falls in multiple jurisdictions, with five law enforcement agencies, there were many different parties involved in incident management.

Developing and implementing a TMP and an IMP for a design-build project is a challenge, as the phasing for a design-build project is not set-up during the RFP stage. The US 285 Project TMP and IMP provided overall strategies and guidance for the project and did not change during construction, with the exception of the points of contact. The project phasing plans remained fairly constant. The TCPs were developed along the way as the project design moved forward. There were a few changes in the TCPs due to unforeseen conditions.

One specific instance where the traffic control plans were changed after completion of initial design was on westbound US 285 at the Kipling Street off-ramp. The project team observed queuing in this area and turbulence in the traffic flow as a result of significant exit of traffic at this interchange. As a result, the off-ramp to Kipling would back up onto US 285, sometimes causing congestion and unsafe conditions. The design-build delivery method allowed the Contractor to provide an innovative solution to this situation. The Contractor introduced a new traffic control strategy which separated the two westbound lanes using concrete barrier, enabling them to move the merge point, reduce merging issues, and improve traffic flow and mobility. This reduced conflicts between through traffic and the vehicles exiting to Kipling Street and also allowed the two lanes to have different elevations, which was helpful to constructability. This innovative traffic control modification improved safety and mobility as well as constructability. Generally the Agency and the Contractor will not be able to quickly issue a change order to allow the use of such an innovative approach in a design-bid-build project. The Contractor has more latitude in a design-build project to make quick alterations in their plans based on problems they encountered in the field. Figure 4-6 illustrates this innovative traffic control strategy.

Figure 4-6. Barrier Separated Through Lanes on Westbound US 285 (Top: in advance of lane separation; Middle: at separation; Bottom: at Kipling off-ramp)

(Source: URS Group, Inc.)

Another example of an adjustment made along the way, which also demonstrates successful project partnership, was how CDOT worked with the Contractor to find acceptable ways to modify the District 6 Lane Closure Strategies for this project to enable the design-build team to create a better TMP. Some of the mobility requirements in the RFP and included in the Contractor's proposal were not possible to follow during construction. One instance was at the Knox/Lowell intersection where the Contractor stated they would keep three lanes open in each direction during peak hours. However, due to a cross drainage issue that came up after construction started, a large portion of the right-of-way was used to remedy the issue. As a result, there was not enough room for three lanes to remain open in each direction. Subsequently, the contract was modified to change the allowable lane closures, and the Contractor implemented a plan to keep two lanes open in each direction during peak hours.

A benefit of the design-build process is that the Contractor has much more input and control of traffic control and phasing than that on design-bid-build projects. A design-builder can tailor project phasing to accommodate the strengths of their construction process. This in turn reduces the time that lane closures are in place, and saves money for mobilization and traffic control operations. For this project, the Contractor and their traffic control personnel formed a task force with CDOT staff to identify issues and work to resolve differences. CDOT felt that this cooperation and coordination led to higher quality traffic control than they would typically get on a traditional design-bid-build project.

As required in the RFP, the Contractor provided a courtesy patrol on the corridor during weekday peak hours. The courtesy patrol provided incident response and towing assistance as well as providing stranded motorists the use of a cell phone and a gallon of gas if needed. CDOT felt that by making the Contractor responsible for incident management, their accountability and attention to incident management increased. As discussed in Aspect #2, the Contractor maintained the Traffic Management Incident Journal to keep a log of all the responses the courtesy patrol made. The incident data were not used to identify potential causes for the incidents or potential improvements to traffic control and management due to resource limitations, but could have been if it was specified as a requirement in the RFP.

One key element of the project, that was not part of the TMP, was the use of photo radar in the work zone by the local law enforcement agencies. Colorado once had a broad photo radar program, which was ended due to legal issues. It had recently been reintroduced for use in work zones. For this project the photo radar program used advance signage with the radar units in vans along the work zone. The result was a 10-mile-per-hour reduction in traffic speeds through the work zone.

Issues and Challenges

There were no issues or challenges identified regarding the implementation of this aspect for this project.

The CDOT project manager did discuss potential challenges with the QA/QC program that could arise in other design-build projects. A concern can arise with specifying what the quality program must include, especially with performance based specifications. One element that was mentioned was the number of people that make up the QA team. Specifying a quantity of persons per dollar value of the project could ensure that a certain level of QA attention will be achieved, and that proposers would not use the quality elements to save on cost. CDOT mentioned that on some past design-build projects, the Contractor had not allocated enough resources to the quality program, and CDOT ended up doing the QA/QC of traffic control for those jobs - something they want to avoid on future projects.

Key Aspect #6 - PS&E Shall Include TMP or Provisions for Contractors to Create a TMP

A TMP will be created and provided by the State or Agency, or the Contractor will develop it subject to the approval of the State prior to implementation.

Successes

Unlike a design-bid-build project, there is no typical PS&E developed before bid for a design-build project. The RFP for a design-build project contains the project requirements and specifications, rather than a full PS&E package. The RFP for the US 285 design-build project included several references to the Rule and material related to seven of the eight key Rule aspects, and implemented aspect #6 as written in the Federal Rule and the CDOT Procedures Document. Book 2, Section 16 of the RFP had extensive language about the creation of the TMP. This part of the RFP identified the timeline (required 30 days prior to NTP2) and content requirements, including mention of the PIP. There was also a section describing the requirements of the IMP. The RFP required the establishment of an MOT task force, which included personnel from both the owner and design-builder. The purpose of this task force was to make sure the TMP was developed in conformance to the RFP, as well as to help create the PIP. The coordination between the task force and the Contractor was a successful partnership, and under the guidance of the task force, a TMP and a PIP were developed and met CDOT's expectations.

CDOT placed safety, quality, and mobility as a priority by inclusion of extensive requirements in the RFP for the US 285 project and awarded a significant amount of points for those portions of the proposals. Such value-based selection safety criteria were essential to getting proposers to maximize safety. The winning proposal not only included superior safety elements but was also able to stretch the resources to an extra mile of reconstruction.

Issues and Challenges

There were no issues or challenges identified regarding the implementation of this aspect.

Key Aspect #7 - Pay Item Provisions - Method or Performance Based

For method-based specifications, individual pay items, lump sum payment, or a combination thereof may be used. For performance-based specifications, applicable performance criteria and standards may be used.

Design-bid-build projects give a large degree of control of the design to the Agency and use prescriptive design and specifications, while design-build projects require the Agency to reduce their control to the design-build Contractor and more often use performance-based specifications in the RFPs. The use of performance-based specifications may enable the Contractor to take risks which can affect work zone safety and mobility in positive or negative ways, and schedule delivery and cost. No specific successes, issues, or challenges were identified for the US 285 Project related to implementing this key aspect. However, some observations relevant to this key aspect are summarized below:

- CDOT used performance-based specifications for some elements of the project, such as lane smoothness for the asphalt and concrete pavement, but none of these specifications addressed work zone safety or mobility.

- The TMP and its components were identified as the Traffic Management line item in the Guaranteed Maximum Price Allocation Form of the contract. $3.2 million was allocated for this task.

- There were no incentives or disincentives for work zone elements on this project, but CDOT did have provisions for a lane rental fee of $750/hour/lane. This fee was based on road user costs.

- CDOT indicated that they would like to use more performance-based specifications in the future. CDOT would also consider specifying the number of people the Contractor uses for QA/QC, especially QA in regards to traffic control to address the weakness of subcontractors in that area. One idea the Project Manager came up with for future design-build projects was to specify about 1 or 2 personnel per $10 million of project value. Specifying this in the RFP can "level the playing field" for elements like safety and traffic control that can be more challenging to specifically test the performance of than elements like material quality.

Key Aspect #8 - Designated Trained Person

The State and the Contractor shall each designate a trained person at the project level who has the primary responsibility and sufficient authority for implementing the TMP and other safety and mobility aspects of the project.

Successes

The Contractor and CDOT had personnel whose responsibilities included implementing the TMP and other safety and mobility related elements as key aspect #8 requires. However, it is not apparent that these people were formally identified as the "designated person".

In the Safety Management Plan, a Project Safety Officer (PSO) is identified. The plan states that the PSO reports directly to the design-build project manager and is responsible for:

- Daily on-site project safety

- Documentation of safety plan activities

- Training and orientation.

The Safety Management Plan and PSO were required per the RFP. The PSO had responsibilities that related to the overall safety and mobility of the project, however, they did not necessarily deal with the implementation of the TMP.

Issues and Challenges

This aspect of the Rule is an element of CDOT's procedures document; however, the requirement was not listed in the RFP. The designated trained person could have been tied to the MOT Task Force, since the RFP required a TCS, superintendent, and a CDOT employee to be members. However, the MOT Task Force seemed more oriented towards the development of the TMP, and not implementation.

An issue that both the Contractor and CDOT agreed on was that the traffic control subcontractor is often the weak link of a design-build project. They stated that one of the daytime TCS working on the US 285 Project was the best they have ever worked with, while some of the others, primarily those working during overnight hours, were not as reliable. Some of the problem might be that the daytime TCS worked with the personnel most knowledgeable about implementing the TMP, while the after-hours and night TCS might not have as much information about the TMP, or oversight and guidance from other staff. This could be because the primary Contractor staff were on site during daytime hours, and a weaker communication channel might exist for getting up-to-date information to those working after hours.

Overall, the requirement for designating a trained person from both the Agency and the Contractor is an aspect of the Rule that should not differ significantly between design-build and design-bid-build projects.

previous | next