Work Zone Training Webinar Louisiana Perspective

Printable Version [PDF 7.65MB]

You will need the Adobe Reader to view this PDF.

Contact Information: WorkZoneFeedback@dot.gov

slide 1

Work Zone Training Webinar Louisiana Perspective

Barry L. Lacy, P.E.

Work Zone/Claims/Audit Engineer

slide notes

None.

slide 2

Louisiana State Motto

slide notes

None.

slide 3

Why Is Temporary Traffic Control Important?

- People die

- People are injured

- Money is lost

- You and your company can be sued

slide notes

Key Message: Discuss the importance of TTC

Est. Presentation Time: 2 minutes

Explanation of Cues/Builds: None

Suggested Comments: TTC is important to the safety of EVERYONE!

Suggested Questions: What is the "4" inside the yellow box?

Additional Information: None

Possible Problems: None

slide 4

What Contractors (and DOTD) Wanted

- Get everyone (DOTD & contractors) "on the same page"

- Clear & concise information (not "at the discretion of the PE")

- Clear set of bid documents – no guessing on work zone safety (night work, # of devices, etc.)

- Get up to speed with the current standards – minimizes exposure in court

slide notes

None.

slide 5

Required Work Zone Training for Construction Inspection Personnel

Flagger

- All personnel (technicians & engineers)

TCT (Traffic Control Technician)

- The basics of temporary work zone traffic control

- All personnel (technicians & engineers)

TCS (Traffic Control Supervisor)

- Advanced temporary work zone traffic control

- All upper level technicians & engineers

- Louisiana Specific when available

slide notes

None.

slide 6

Required Work Zone Training for Construction Inspection Personnel (cont'd)

- ATSSA – preferred source of training

- Louisiana Specific Refresher Course (TCS) – will be ready soon with implementation this year

- Training records are readily maintained & tracked

- Certification not required – only course completion

- Refresher training required every 4 years

slide notes

None.

slide 7

Work Zone Training (DOTD & Contractors)

| Flagger | TCT | TCS |

|---|---|---|

| 2041 | 2552 | 2114 |

slide notes

None.

slide 8

Standard Specification

Section 713.08

Traffic Control Management

Important Points to Ponder

slide notes

None.

slide 9

Traffic Control Management

| Year | Cost |

|---|---|

| 2004–2005 | $177/Day |

| 2006 | $148/Day |

| 2007–on | Part of Temporary Signs & Barricades |

slide notes

None.

slide 10

Requirements

TCS shall have:

- a set of all contract documents relating to traffic control or traffic staging

- a current copy of the MUTCD

- a current copy of Louisiana Work Zone Traffic Control Details

slide notes

None.

slide 11

713.08(a) Authorization:

The contractor shall submit to the engineer a copy of the TCS's and TCT's current authorization.

Currently, ATSSA & AGC are acceptable, plus any others that contractors can justify.

Refresher course every 4 years required

slide notes

None.

slide 12

713.08(b) TCS Duties:

- TCS – may have other assigned duties, but must be readily available at all times to perform TCS duties as required in the contract

- A minimum of one TCT shall be required on site during working hours

- Someone in charge of traffic control (TCT or TCS) shall be on site at all times.

slide notes

None.

slide 13

713.08(b) TCS Duties: (cont'd)

- Responsible for the training of flagging personnel

- Ensures that all flagging done on the project is in compliance with the MUTCD and the Louisiana Work Zone Traffic Control Details

- Police – OK when used as flaggers, as long as they meet the flagger requirements and are being used ONLY as flaggers (not police)

slide notes

Do not abandon the job, not around police car, not talking on police radio, etc.

slide 14

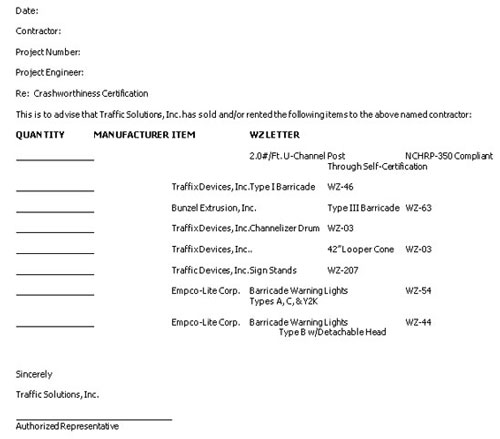

Crashworthiness Letters (WZ Letter)

slide notes

None.

slide 15

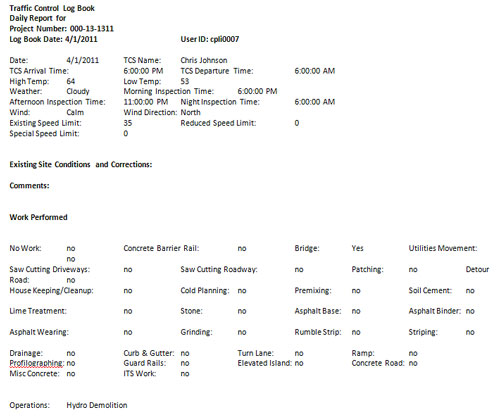

713.08(d) Traffic Control Diary:

- TCS maintains a project traffic control diary online within Site Manager

- TCS keeps the traffic control diary current on a daily basis, and electronically signs each daily entry (contemporaneous)

- Subject to LA R.S. "Filing or Maintaining False Public Records"

- Failure to submit = $150/calendar day

slide notes

None.

slide 16

713.08(d) Traffic Control Diary: (cont'd)

slide notes

None.

slide 17

Excerpt From a Traffic Control Supervisor's Diary (not good)

"Came out today and had trucks set to go on different project. After getting this done, I left yard and went to plant in Metropolis, then went to Hwy 123 job where Jim had started laying binder mix. He had the first load on job site and I had about 11 other trucks hauling to him. I stayed until he got further down the road & had about 6 or 8 trucks unloaded. I also talked to the two girls unloading trucks and asked them to try and clean apron on trucks better. Went to Hwy 456, and got with Tom & Jerry to see what was going on, then came back to Hwy 789 on Jim's job, where I didn't get to see much except men asleep on job until I saw him at the store up the road. Came back to office for rest of day until time to go on. Had trucks set up for next day."

slide notes

None.

slide 18

713.08(e) Inspection of Traffic Control:

- TCS – responsible for the inspection of all traffic control devices every calendar day

- Inspection may be delegated to the TCT, except on high profile/speed/ADT (TCS)

- The "Quality Guidelines for Work Zone Traffic Control Devices" (ATSSA) – used to evaluate the condition of the traffic control devices to determine if acceptable for use

slide notes

None.

slide 19

ATSSA Quality Guidelines Distribution

- 600 pamphlets to DOTD personnel

- 200 pamphlets to 70 different contractors

- Distributed since 2005

Acceptable/Marginal/Unacceptable

slide notes

Given out at lettings, mailed, etc.

slide 20

713.08(e) Inspection of Traffic Control:

- Inspected by the TCS on weekends, holidays, or other non-work days at least once per day

- Inspected by the TCS at least once a week during nighttime periods

slide notes

None.

slide 21

713.08(f) Failure to Comply:

- PE, Work Zone Engineer, or Statewide Traffic Control Specialist – may suspend all or part of the contractor's operation(s) for failure to comply with the approved "Traffic Control Plan" or failure to correct unsafe traffic conditions within a reasonable period of time

- Notification is given to the contractor in writing

- Serious deficiencies shall constitute in the contractor's operations being shut down until such time as he can demonstrate that he can meet the specification in its entirety

slide notes

None.

slide 22

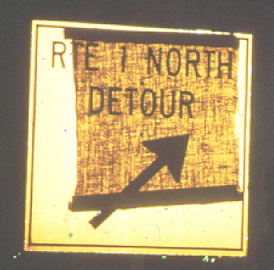

Inspection Deficiencies

- Major = 2 pts, Minor = 1 pt

- Signs

- Major – not clipped in properly, wrong application, not telling the truth, using burlap to cover signs

- Minor – incorrect spacing/sheeting/size/posts

slide notes

None.

slide 23

You can see through burlap at night!

slide notes

Key Message: Burlap is not an acceptable covering

Est. Presentation Time: Less than 1 minute

Explanation of Cues/Builds: None

Suggested Comments: You can see through burlap. Light bounces back!

Suggested Questions: None

Additional Information: Photo sources unknown

Possible Problems: None

slide 24

Inspection Deficiencies

- Barricades

- Major – not crashworthy

- Minor – chevrons pointed in wrong direction

slide notes

None.

slide 25

Inspection Deficiencies (cont'd)

- Flagging Operations

- Major – not qualified, wrong location, no lime green vest

- Minor – pole too short (6'), sign too small (<18")

slide notes

None.

slide 26

Qualified Flagger??

slide notes

None.

slide 27

Inspection Deficiencies

- Message Signs/Arrow Boards

- Major – wrong message, misapplication (taper, flagger, etc.)

- Minor – no delineation, using them as an arrow board

slide notes

None.

slide 28

Appropriate Work Zone Message??

slide notes

None.

slide 29

Using Message Board as Arrow Board??

slide notes

None.

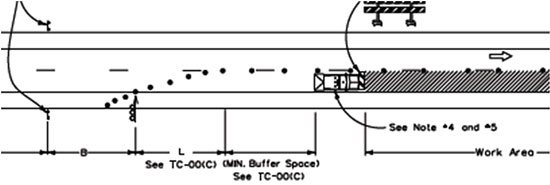

slide 30

Inspection Deficiencies

- Miscellaneous

- Major – ballast tied to moveable stand (not crashworthy), equipment parked in clear zone, incorrect flare for concrete barriers (outside to clear zone or crash cushion), taper too short, TMAs not being moved as the work moves down the highway

- Minor – wrong speed limit or lights, unkept roadway

slide notes

None.

slide 31

Incorrect Placement of TMAs?

slide notes

None.

slide 32

Tapers Too Short??

slide notes

None.

slide 33

Non-reflectorized Netting??

slide notes

None.

slide 34

Crashworthy??

slide notes

None.

slide 35

713.08(f) Failure to Comply:

- We reserve the right to revoke or de-certify the TCS for gross neglect of his or her duties.

- "certification is a privilege"

- "safety hazard to the workers and the public"

- "violated procedures and practices of the MUTCD"

- TCS retakes TCS course – subject to a 90 day probationary period at the discretion of the Department

- Approximately 12 TCSs decertified in the last 1½ years – some companies have demoted or fired these individuals

slide notes

None.

slide 36

Protecting Blunt Ends When Removing Guardrail

- Old method – Type III barricade & 3 devices – NO PROTECTION!!

- Option 1 – Remove & replace guardrail the same day

- Option 2 – Install and maintain an NCHRP 350 TL-3 or MASH approved device until new guardrail is installed

- Non-NHS routes with shoulders less than 8 feet wide – if TL-3 cannot be installed due to field conditions, TL-2 is acceptable

- New guardrail should be installed within seven (7) days.

slide notes

None

slide 37

The Bottom Line

- Take pride in your work zone

- Have workers wearing appropriate safety garments (not worn or ragged) – they will command more respect from the traveling public

- Establish a work zone that any driver (young or old) could navigate easily

- TTC sets the tone for the entire project – if it doesn't look good or isn't correct, motorists won't respect you, and expect sloppy inspection & construction

- TTC is your controlling work item each and every day!!!

slide notes

None

slide 38

Louisiana's Construction Budget?

slide notes

None.

slide 39

Questions?

Barry L. Lacy, P.E.

Work Zone/Claims/Audit Engineer

barry.lacy@la.gov

(225) 379-1584

slide notes

None.