How Do I Get What I Need? Work Zone ITS and 23 CFR 940

slide 1: How Do I Get What I Need? Work Zone ITS and 23 CFR 940

Karen Gilbertson

FHWA Kansas

May 20, 2013

Bettendorf, Iowa

slide notes:

Kristi Pyle asked me to speak on the topic of Work Zone ITS at this year's Work Zone Peer Exchange. Often we get started talking about the benefits of this or that technology. I wanted to step back and present a different view. Work Zone ITS, also called Smart Work Zones can be considered as an innovation in technology. And 23 CFR is the Code of Federal Regulations. Title 23, part 940, section 11 describes Project Implementation which includes a systems engineering analysis. (so my talk includes Work Zone ITS and SE)

slide 2: What Do Motorists Want?

- "Road Construction! I really don't want to detour or find another route"

Translation: They are not going to make it easy for us as we plan our construction and lay out our work zone

- "Looks like they expect me to slow down and shift lanes!"

Translation: We expect them to follow our instructions and drive more alertly through the work zone

slide notes:

What do Motorists Want? How do our roadways function for the everyday driver? We are creatures of habit. We don't want to go out of our way if we don't have to. Heightened alertness? How do we manage that while we are carrying on conversations with our kids, phone conversations with the trucking company dispatcher. What about that ball game, that riveting political discussion on talk radio, or my favorite music that has me moving to the beat! Not mentioning that large, hot or cold beverage of choice or that messy burrito or ice cream cone.

slide 3: Variability is Normal - And the Problem

- Morning/Afternoon Rush Hour

- Get out of town – it's Friday

- Ball Games and Concerts

- Snow, Sleet, Heavy Rain

- Nighttime

- Young Drivers – Old Drivers

- Heavy Traffic

slide notes:

The complaints we mentioned in Slide 2 stem from the variability that exists and our frustrated efforts to separate it out into "boxes!" Until humans no longer "drive" cars, we have to live with variability as a fact of life and traffic!

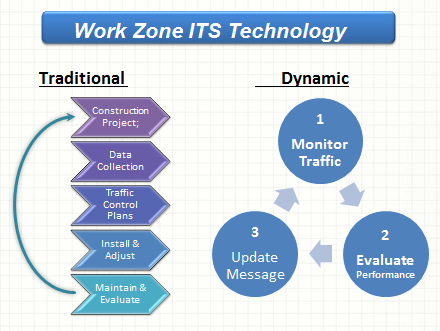

slide 4: Work Zone ITS Technology

slide notes:

Traffic control plans are developed to facilitate construction of a roadway project. Factors considered in the design include those addressed in the issue of variability. In either cases the traffic control plan is intended to address safety and efficiency throughout the work zone. Work Zone ITS has the capability to substantially improve the performance of traffic movement in response to variability. This reduces complaints!

slide 5: Work Zone ITS Technology

- Better

- Benefits to Road Users & Agencies

- Ongoing performance measurement

- Smarter

- Solves problems that are difficult to address with standard work zones

- Addresses different levels of demand

- Faster

- Moves traffic through a work zone dynamically

slide notes:

Walk through the slide. This is how technology applications are "sold" to the transportation industry. This technology has been around for a while. Maybe we tried it ten years ago or so and didn't have a good experience. However it had not been widely implemented in spite of the potential to save cost, improve safety, reduce congestion, or all three.

slide 6: Readily Available Work Zone ITS

Name Your System or Vendor Here:

___________________________________________

NCHRP SYNTHESIS 20–05/Topic 45–06(new) Active and Passive Methods for Slowing Traffic in Work Zone Technology and Procedure

slide notes:

What systems can you name? Who is the vendor? Are new systems coming into the market? Refer to the NCHRP Synthesis which is new and promises tobe an excellent in depth look at what we are trying to accomplish with Work Zone ITS.

slide 7: Getting It Right is Important

New focus on technology means

- New opportunities for success

- New consequences of failures

- Greater interest from industry

- More visibility and scrutiny

- Federal regulations governing ITS projects

- Federal regulations governing procurements

slide notes:

Getting it right is important. Walk through the slide –––––– There are 2 issues that continue to hinder smart work zones and ITS systems in general. These are funding and a consistent implementation process that aligns the agency objectives, needs, operations and maintenance capabilities with requirements that promote concise specs that meet those needs at a reasonable cost and with the desired level of functionality.

slide 8: What is Intelligent Transportation Systems?

- According to 23 CFR 940, "ITS means electronics, communications, or information processing used singly or in combination to improve the efficiency or safety of a surface transportation system."

- Smart Work Zone deployments meet this definition…

slide notes:

What is ITS? It is defined in 23 CFR 940 as…

slide 9: What is ITS?

slide notes:

Weather sensors, DMS, cameras, automated snow gates, vehicle detection sensors… Some but not all are used in Smart Work Zones.

slide 10: 23 CFR 940.11 Requirements

- All ITS projects must be developed using a Systems Engineering (SE) analysis

- The analysis shall be on a scale commensurate with the project scope

- SE analysis shall address (7) requirements

- The purpose is to ensure that agencies get what they (and their stakeholders) need

slide notes:

Walk through the slide…

slide 11: Seven Requirements of SE Analysis

- Identify portions of the regional ITS architecture being implemented

- Identification of participating agencies roles and responsibilities

- Requirements definitions

- Analysis of technology options to meet requirements

- Procurement options

- Identification of applicable ITS standards and testing procedures

- Procedures and resources necessary for operations and management of the system

slide notes:

This is what we want to accomplish by using SE.

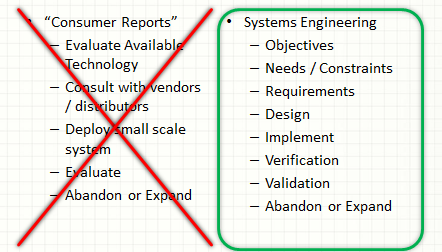

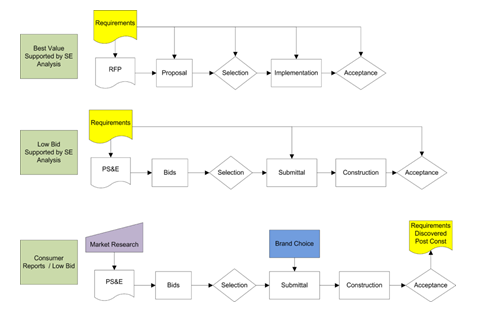

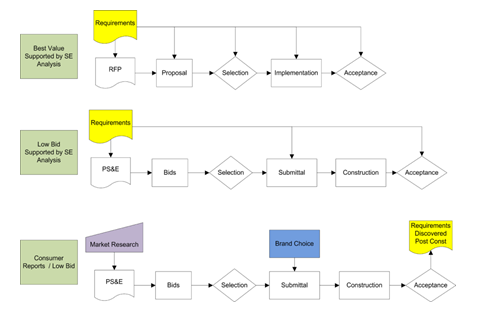

slide 12: How Do We Deploy SWZ?

Focus on the process, not the technology!

slide notes:

Just as I might study up to purchase a clothes washer or a new car – There are 2 approaches to smart work zones:

- Look at the technology.

- Look at the process.

The correct approach is to focus on the process, not the technology. We don’t have the time or the funding to not get it right.

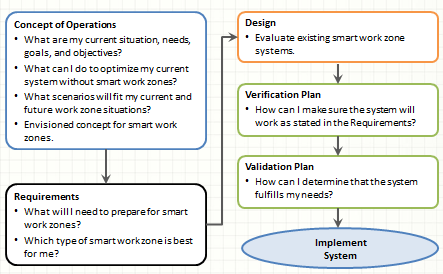

slide 13: SWZ – The Systems Engineering Process

slide notes:

Walk through the slide – if time use this as well → The systems engineering process for ASCT:

- Traffic engineering dept. (with possible assistance of consultant) develops a Concept of Operations (ConOps).

- City must first look at optimizing their current system before deploying ASCT.

- Traffic engineering dept. (with possible assistance of consultant) defines their Requirements for adaptive signal control.

- Traffic engineering dept. (with possible assistance of consultant) designs system for adaptive signal control.

- Traffic engineering dept. (with possible assistance of consultant) develops a Verification Plan. This is an important item, as it is how the Traffic engineering dept. will verify that the implemented system meets their defined Requirements.

- Traffic engineering dept. (with possible assistance of consultant) develops a Validation Plan. This is an important item, as it is how the Traffic engineering dept. will validated that the implement system meets their ConOps.

- If traffic engineering dept. uses Federal-aid funding for the systems engineering process, they must follow the latest ODOT/FHWA “Guidelines for the Administration of Consultant Contracts” for their engineering/architectural consultant services contract.

How to implement ASCT – Does this apply to Smart Work Zones?:

After the traffic engineering dept. completes systems engineering process and has produced the systems engineering documentation, they may:

- Let contract through competitive bidding process, if they or their consultant has prepared detailed design plans, contract, and bid package.

- Federal-aid funded projects must follow ODOT Federal-aid construction/contracting process.

- Procure system through non-engineering/non-architectural vendor solicitation/RFP, if they expect a vendor to deploy a system meeting their detailed requirements.

- Non-engineering/non-architecture procurement follows 49 CFR 18.36.

- This is the process that OKC followed with their extensive coordinated signal system project.

slide 14: Basic Systems Engineering Deliverables

- Concept of Operations

- Requirements

- High Level Design

- Verification Plan

- Validation Plan

slide notes:

Simply, it boils down to these 5 deliverables!

- The typical civil engineering department is not familiar with technology projects.

- Technology projects have a high failure rate, event within technology industry.

- Work Zone ITS may not be the answer to the DOTs work zone problem. If this is the case, a deployed Work Zone ITS system is almost a guaranteed, and expensive, failure.

- Poor roadway/intersection geometry, poor or no access control, poor land use zoning, saturated traffic flow, etc. can’t be fixed through ASCT.

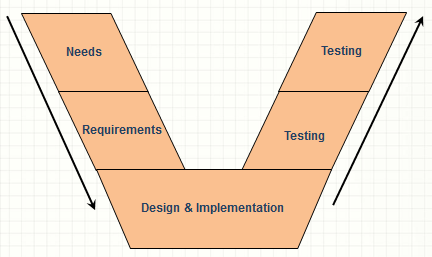

slide 15: Systems Engineering V Diagram

slide notes:

You may have seen a more elaborate V Diagram. I think it is simpler to look at it like this. These 5 areas. The set-up of the V is to show how the right side traces back to the work done in the first phase.

slide 16: Work Zone ITS – What are the risks?

- Technology is new to most and still evolving.

- Most systems have very limited track record.

- Increased complexity, very dependent upon other stuff (communications, detection, staff).

- Often pitched as "one size fits all" silver bullet.

- What is the failure rate?

A Work Zone ITS system may not be the answer to your problem.

slide notes:

- The typical civil engineering department is not familiar with technology projects.

- Technology projects have a high failure rate, event within technology industry.

- Work Zone ITS may not be the answer to your work zone problem. If this is the case, a deployed work zone ITS system is almost a guaranteed, and expensive, failure.

- Poor roadway/intersection geometry, poor or no access control, poor land use zoning, saturated traffic flow, etc. can’t be fixed through ASCT.

slide 17: The Role of Systems Engineering

- Understand the problem

- Minimize the risk.

Where to start:

The Guide to Contracting ITS Projects and its companion web-based tool, available at http://www.citeconsortium.org/Model/index.htm

slide notes:

The role of systems engineering:

- Understand the problem.

- Once the problem is understood, then steps can be taken to minimize the risk of failure.

slide 18: Purpose of SE Model Documents

- Evaluate need for Work Zone ITS

- Help agencies identify verifiable, needs-driven requirements for evaluating design and implementation choices

- Model documents greatly reduce systems engineering effort by providing wording and documentation…

- …but agencies still must identify their needs

slide notes:

Walk through the slide – the Purpose of SE model documents, with the text on the slide.

- The typical civil engineering department is not familiar with technology projects.

- Technology projects have a high failure rate, event within technology industry.

- ASCT may not be the answer to city’s traffic problem. If this is the case, a deployed ASCT system is almost a guaranteed, and expensive, failure.

- Poor roadway/intersection geometry, poor or no access control, poor land use zoning, saturated traffic flow, etc. can’t be fixed through ASCT.

slide 19: Procurement Regulations

- Proprietary Materials (23 CFR 635.411)

- Certification of no available competitive product

- Uniquely fulfills the requirements imposed on the product

- Achieves synchronization with existing systems

- Public Interest Finding for proprietary purchase despite alternative available competitive products

- Limited experimental application

- Certification of no available competitive product

- Systems Engineering provides justification

slide notes:

None

slide 20: What is Commercial-Off-the-Shelf?

FAR definition of COTS: a non–developmental item of supply that is both commercial and sold in substantial quantities in the commercial marketplace, and that can be procured or utilized under government contract in the same precise form as available to the general public.

slide notes:

None

slide 21

slide notes:

None

slide 22: Outcome of the Process

- Informed Technology Selection

- Agency Needs and Objectives

- Agencies Policies

- Operations and Maintenance Capability

- Resources

- Expansion

- Equipment Life Cycle

- Procurement Options

- Meet Federal Rule 940 and Rule 635 requirements for Federal Funding

slide notes:

None

slide 23: Tailor the SE Process Based on Risk

Rick Factor

- Project Type

- Project Complexity

- No. of Stakeholders

- No. of Interfaces

- Technology

- Custom Development

- Criticality

- Project Understanding

- Staff Experience

Low Risk vs High Risk

slide notes:

None

slide 24

slide notes:

None

slide 25

Credits: Richard Jury, OK Div-FHWA, Eddie Curtis, Rick Denney, Paul Olson, Ed Fok - FHWA Resource Center, John Perry, NE Div, Sarah Tracy, NDOR

Systems Engineering Process

Karen Gilbertson

ITS/Traffic Operations Engineer

(785) 271-2448 ext 209

Karen.gilbertson@dot.gov

slide notes:

None

Return to List of Presentations