Iowa DOT ABC Program Overview, Lessons Learned, Program Direction

slide 1: Accelerated Bridge Construction in Iowa

Ahmad Abu-Hawash, PE

Iowa Department of Transportation

Office of Bridges and Structures

Denver, Colorado

June 5-6, 2012

slide notes:

None

slide 2: Outlines

- ABC/PBES Concept, Advantages, & Disadvantages.

- Iowa's ABC Deployment Strategy

- Case Study: Keg Creek Lessons Learned

slide notes:

- I will briefly talk about the concept of accelerated bridge construction and prefabricated bridge elements and systems, its advantages and disadvantges.

- Iowa's ABC deployment strategy

- And finally present a case study

slide 3: PBES

- Prefabricated Bridge Elements and Systems (PBES): it is a strategy to accelerate bridge construction that employs prefabricated individual Elements such as beam, deck, abutment footing, pier column, pier cap, etc. Or entire superstructure System that is assembled off-site and moved into place.

slide notes:

What is PBES?

slide 4: Why use ABC?

- To deal with schedule constraints

- Limited time-window due to special events

- Emergency replacement due to natural disasters, accidents, or intentional acts

- To minimize impact on local traffic

- Access to business

- Commuters

- Essential services

- To deal with the unavailability of suitable detour

slide notes:

- To deal with schedule constraints such as limited time window due to special events or emergency replacement due to natural disasters, accidents, or intentional acts.

- To minimize impact on local traffic by providing access to businesses, commuters, and essential services such as hospitals and fire protection

- To deal with the unavailability of suitable detours.

slide 5: ABC: Benefits

- Reduced public inconvenience

- Improved public perception

- Improved road users and workers safety

- Reduce negative economic impact on local businesses

- Perhaps improve the durability of the structure

slide notes:

The primary benefits of ABC:

- Reduced public inconvenience: by not having to go through construction zone or take a detour for full construction season (typically six months or more)

- Improved public perception: an example is driving in construction zone on Saturday with traffic restriction and no work being done

- Improved road users/workers safety: shorter exposure to construction hazard for both the public and workers

- Reduce negative economic impact on local businesses: people try to avoid construction zone therefore local businesses suffer

- Perhaps improve the durability of the structure: in the case of precast components fabricated in controlled environment quality is improved

slide 6: ABC: Disadvantages

- Substantial increase in construction cost: fewer bridge replacements

- Contractors are generally uncomfortable with the PBES concept: higher cost

- Requires the development of new design standards and specifications: higher design cost

slide notes:

If you are only considering direct cost, there are definite disadvantages associated with ABC

slide 7: Iowa DOT ABC Deployment Strategy

- Develop skills and design details through demonstration projects (IBRD, HfL, SHRP2, ..)

- Invest in research and include laboratory and field testing to confirm constructability and performance.

- Participate in national pooled fund studies

- Involve local construction industry and hold ABC workshops.

- Develop policies for ABC

slide notes:

Despite the direct cost disadvantages, there is a definite need for ABC in Iowa.

Keeping in mind that we have to be selective where to use ABC, we needed to develop a deployment strategy.

The first step in the deployment strategy was to Develop skills and design details through demonstration projects.

We took advantage of federal grants such as IBRD, HfL, and SHRP2.

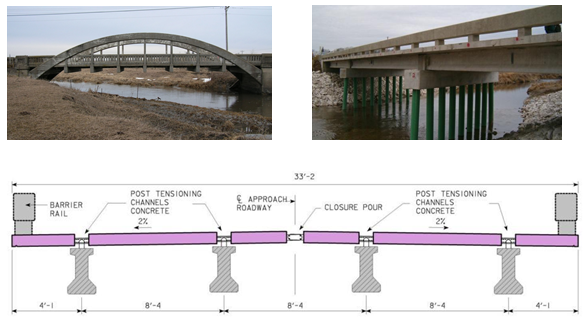

slide 8: Boone County Mackey Bridge

slide notes:

Boone County Mackey Bridge was the first ABC demonstration project in Iowa using prefabricated components.

slide 9

slide notes:

Consisting of precast pier caps and abutment footings

slide 10

slide notes:

With precast prestressed concrete beams and deck panels

slide 11: Madison County

slide notes:

The second demonstration project was a single-span bridge on local road in Madison County.

slide 12

slide notes:

Consisting of precast concrete box girders on precast abutment footings

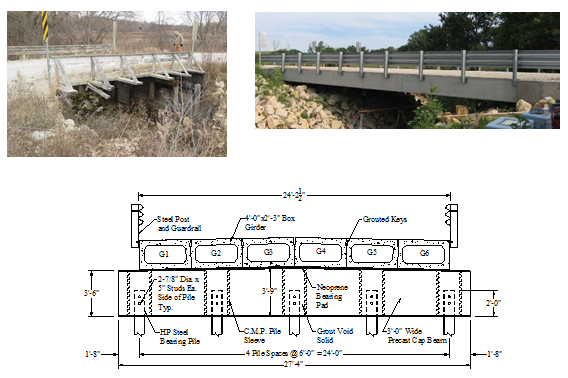

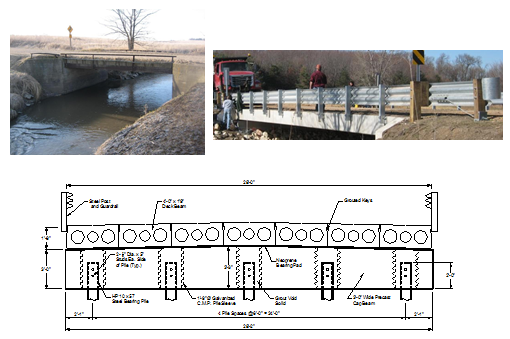

slide 13: Buena Vista County

slide notes:

Then we did a second generation single-span total precast bridge in Buena Vista County.

slide 14

slide notes:

Using precast concrete box girders on abutment footings

slide 15

slide notes:

But this time we included precast wings

slide 16: 24th Street Bridge

slide notes:

Based on the lessons learned from the smaller demonstration projects on the low volume roads, now we are ready for a major interchange project.

slide 17: Overview

- Reconstruct the 24th St Interchange over I-80/I-29

- Replace existing structure with a two-span CWPG

- Use staged construction to maintain one-lane traffic in each direction plus a turning lane

- ABC techniques used:

- Full-Depth Precast Deck Panels

- High Performance Concrete and Steel

- Structural Health Monitoring

- Fully Contained flooded backfill

- A+B Bidding

- ITS

slide notes:

The purpose of this major interchange project in Council Bluffs Iowa was to:

- Reconstruct the 24th St Interchange over I80/I29

- Replace the existing structure a two-span CWPG bridge

- Use staged construction to maintain one-lane traffic

- The ABC techniques used:

slide 18

slide notes:

Here is some of the ABC components used

slide 19: Accelerated Bridge Approach Replacement

slide notes:

Our demonstration program was not limited to bridges only but we also experimented with precast pavement, primarily for bridge approaches.

Since traditional bridge approach replacement requires up to two weeks of lane closure, accelerated construction makes a lot of sense.

slide 20: O'Brien County Project

slide notes:

The first project was on Iowa 60 in O'Brien County where we used precast concrete panels for the first 75' of each approach

slide 21

slide notes:

The panels were posttensioned in both directions

slide 22: Bremer County Project

slide notes:

Unlike the first project, on this bridge approach project on US 65 in Bremer County we required a maximum of 8-hour lane closure at a time and night work

slide 23

slide notes:

Here is the placement of precast panels

slide 24

slide notes:

The contractor showed innovations by building specialized equipment for panel placement

slide 25: Iowa DOT ABC Deployment Strategy

- Develop skills and design details through demonstration projects (IBRD, HfL, SHRP2, ..)

- Invest in research and include laboratory and field testing to confirm constructability and performance.

- Participate in national pooled fund studies

- Involve local construction industry and hold ABC workshops.

- Develop policies for ABC

slide notes:

Another step in the strategy is to invest in research.

Anytime we tried something new, we included testing components and SHM to confirm constructability and performance.

slide 26: Iowa DOT ABC Deployment Strategy

- Develop skills and design details through demonstration projects (IBRD, HfL, SHRP2, ..)

- Invest in research and include laboratory and field testing to confirm constructability and performance.

- Participate in national pooled fund studies

- Involve local construction industry and hold ABC workshops.

- Develop policies for ABC

slide notes:

The most cost effective way to do research is through national pooled fund studies

slide 27: Iowa DOT ABC Deployment Strategy

- Develop skills and design details through demonstration projects (IBRD, HfL, SHRP2, ..)

- Invest in research and include laboratory and field testing to confirm constructability and performance.

- Participate in national pooled fund studies

- Involve local construction industry and hold ABC workshops.

- Develop policies for ABC

slide notes:

And of course involve the local construction industry and hold workshops.

We have very good relationship with the industry in Iowa

slide 28: Iowa DOT ABC Deployment Strategy

- Develop skills and design details through demonstration projects (IBRD, HfL, SHRP2, ..)

- Invest in research and include laboratory and field testing to confirm constructability and performance.

- Participate in national pooled fund studies

- Involve local construction industry and hold ABC workshops.

- Develop policies for ABC

slide notes:

And the last step is to develop policies for ABC

slide 29: ABC Policies

- The policy for ABC implementation is being developed. A target completion date of July 1st.

- Assembled a team of engineers from various disciplines to develop the policy with strong support from top management.

- The policy will utilize decision making tools such as:

- ABC Rating Score & Flow Chart similar to Utah as a first level filter

- AHP Decision Making Tool as a second level confirmation and further evaluation of alternatives.

slide notes:

None

slide 30: ABC Implementation Barriers

- Funding to offset ABC construction cost – need to identify new revenues or alternative funding

- Resistance from some local contractors to ABC – working with industry to change the climate

- Limited contracting methods – since Design Build (DB) is not allowed in Iowa we are looking at the partial DB option

- Design aids – we are working on ABC design policies, specifications and standard details.

- Limited experience in ABC design – several ABC projects have been identified to attain experience for our engineers.

slide notes:

Some of the barriers in the way of ABC implementation

slide 31: Case Study: Keg Creek Lessons Learned

slide notes:

None

slide 32: Background

- SHRP2 – R04 Research Team needed to demonstrate ABC design concept for typical multi-span stream crossings – a common rural bridge replacement

- Proposed a demonstration project in Iowa

- Successful project may pave the way for developing national ABC standards

- A bridge on US 6 over Keg Creek in Pottawattamie County met the objectives

slide notes:

- As a part of phase 2 of the SHRP2-R04 project the research team needed to demonstrate the ABC design they developed for typical multi-span stream crossings.

- So they proposed a demonstration project in Iowa

- A successful project would help pave the way for developing national ABC standards

- The bridge on US 6 over Keg Creek in Pottawattamie County met the objectives

slide 33: Project Data

- Design: HNTB (M. LaVoilette, B. Sivakumar, F. Hubbard, and K. Price)

- Owner: Iowa DOT (D. Evans ∇ Design Review, B. Flippin & G. Feazell)

- Testing: ISU (M. Rouse, B. Phares, D. Hartwell, D. Wood, and T. Wipf)

- Contractor: Godbersen-Smith (K. Triggs & M. Freier) $2,658,823 (7 bidders from $2.66M to $3.99M)

- Unit cost: $231 per sq.ft. ($124 estimated for conventional)

- Contract period:

- Phase 1 – Drilled shaft installation (9 working days)

- Phase 2 – ABC Period (14 calendar days)

- Phase 3 – Revetment, grading, and flumes (20 working days)

- Incentive/Disincentive on 14 days ABC: $22,000 per day

- ABC approximate start date: 9/19/11 (actual 10/17/11)

- SHRP2 funds: $250,000 (M. Starnes – Program Officer)

- HFL funds: $600,000 or 20% (M. Huie – Program Coordinator)

slide notes:

None

slide 34: EXISTING BRIDGE

- Built in 1953

- 3 spans 53'6",73',53'6"

- Moderate sized, typical rural crossing

- Small, meandering stream

- Narrow bridge width on primary road system

- Sufficiency rating 33

180' x 28'-0 Continuous concrete girder bridge

slide notes:

- The existing structure is 180 by 28 continuous concrete girder bridge

- Built in 1953

- 3 span

- Typical rural crossing over small meandering stream

- It is FO because of the narrow width with sufficiency rating of 33

slide 35: Why Keg Creek?

- Typical rural, moderate size stream crossing in Iowa. Indicative of many bridges throughout the mid-west and country. SHRP2 looking to standardize ABC design plans.

- Detour: 22 mile detour less desirable for traveling public over 4 to 6 month period versus 2 week ABC period.

- Schedule: already programmed for 2011 construction.

slide notes:

- Keg Creek was a perfect fit for the R04 project because it is a rural, moderate size stream crossing which is a representative of many bridges in Iowa, the midwest, and the country

- Detour length was a factor because anytime you reduce public inconvenience from six months to 14 days is good thing

- Schedule: the research team was looking for a project in 2011 and Keg Creek was already scheduled for 2011 construction

slide 36: Why Keg Creek?

- Size of bridge favorable for pilot project in term of cost.

- Low AADT = ideal for demonstration site.

- Narrow existing bridge width allowed for drilled shaft foundation construction prior to bridge closure (outside of ABC).

- Bridge geometry: 0 degree skew and flat grade.

slide notes:

None

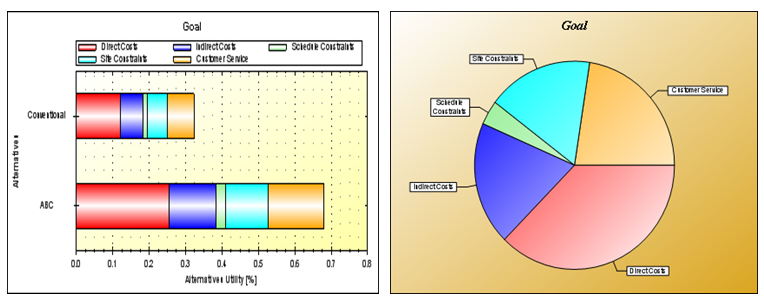

slide 37: AHP Analysis

slide notes:

None

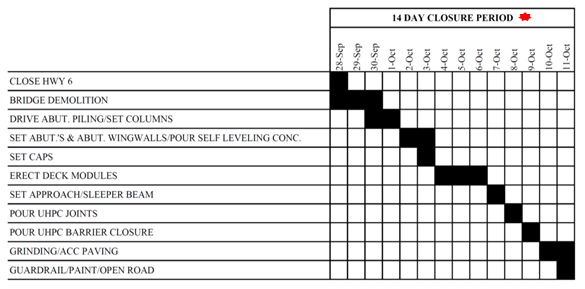

slide 38: 14-Day ABC Timeline

(as proposed by the Contractor)

Actual ABC period: October 17 – November 1

slide notes:

None

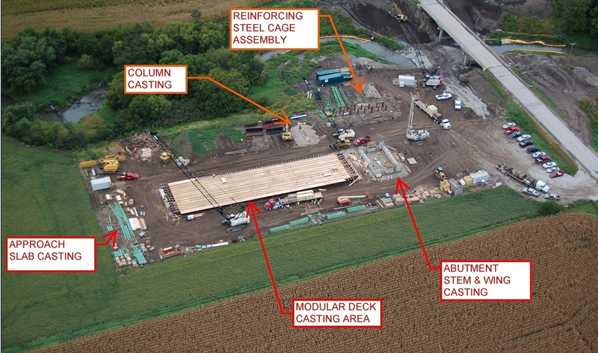

slide 39: Iowa Bridge Farm

(Phase 1)

slide notes:

None

slide 40: Precast Substructure Components Casting

(Phase 1)

slide notes:

None

slide 41: Superstructure Modules – Structural Steel Assembly

(Phase 1)

slide notes:

None

slide 42: Superstructure Modules – Deck Forming

(Phase 1)

slide notes:

None

slide 43: Deck Concrete Placement

(Phase 1)

slide notes:

None

slide 44: Drilled Shaft Construction

(Phase 1)

slide notes:

None

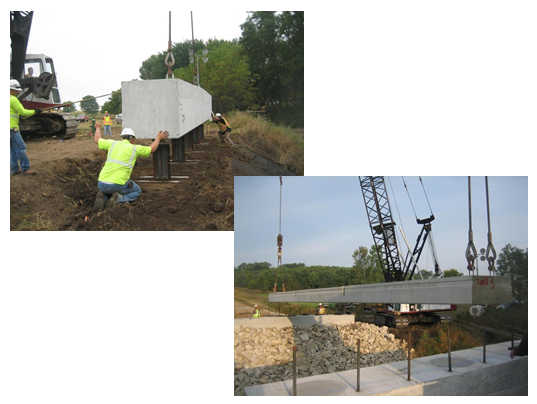

slide 45: Abutment / Wing Erection

slide notes:

None

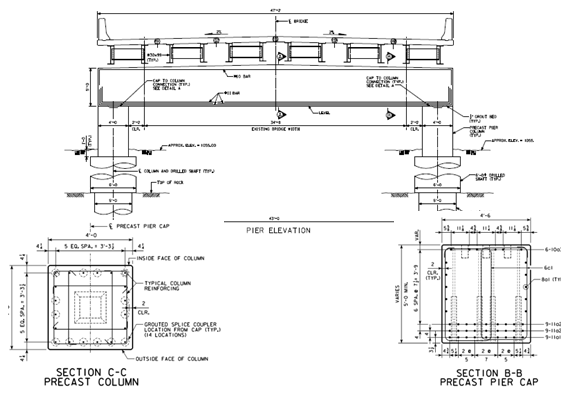

slide 46: Pier Details

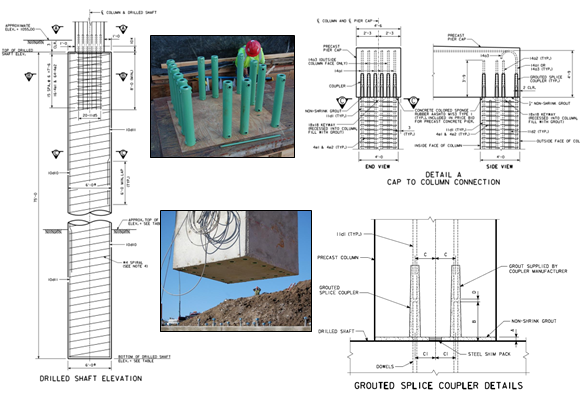

slide notes:

None

slide 47: Pier Connection Details

slide notes:

None

slide 48: Column Assembly

slide notes:

None

slide 49: Bedding and Coupler Grouting

slide notes:

None

slide 50: Cap Beam Assembly

slide notes:

None

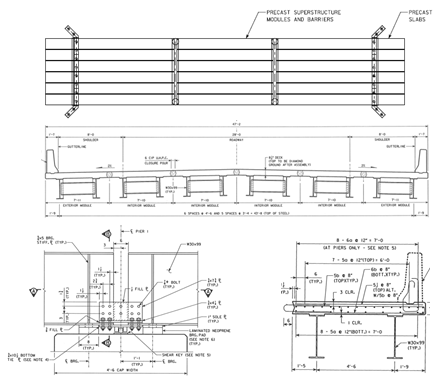

slide 51: Modular Superstructure Details

slide notes:

None

slide 52: Superstructure Module Transport

slide notes:

None

slide 53: Module Assembly

slide notes:

None

slide 54: Module Assembly

slide notes:

slide 55: Final Module Placement

slide notes:

None

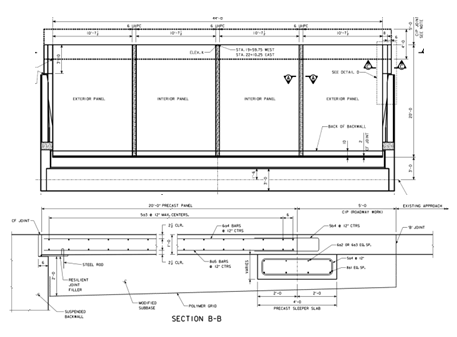

slide 56: Precast Approach Slab Details

slide notes:

None

slide 57: Flooded Backfill System

slide notes:

None

slide 58: Precast Approach Preparation

slide notes:

None

slide 59: Precast Approach Slab Placement

slide notes:

None

slide 60: UHPC Placement

slide notes:

None

slide 61: Completed Bridge

slide notes:

None

slide 62

slide notes:

None

slide 63: Conclusions

- ABC design concept was successfully demonstrated but there were some challenges along the way.

- Post construction review identified problem areas, as expected, and provided recommendations for improvements which will be documented in the final report.

- As the result of this project (and other past ABC projects), Iowa DOT gained a better understanding of risks and benefits associated with ABC and is developing ABC policy.

slide notes:

None

slide 64: Questions?

Project Website: http://www.iowadot.gov/us6KegCreek/

slide notes:

None

Return to List of Presentations