Behavioral/Agent-Based Supply Chain Modeling Research Synthesis and Guide

EXECUTIVE SUMMARY

Freight planning has received significant attention in recent years, not only due to Federal emphasis on freight in the Moving Ahead for Progress in the 21st Century (MAP-21) Act and the Fixing America's Surface Transportation (FAST) Act, but also because of the vital role freight plays in the economy. Transportation agencies are increasingly examining details of freight forecasts to better understand supply chain decisions and ways to improve freight mobility. In addition, the trucking industry is on the verge of transformation with automated and connected vehicle technologies and drone deliveries. Freight forecasting models need to be sensitive to the elements of this ever-changing environment so that scarce transportation funding can be targeted towards improvements that will have the greatest benefit on freight movement.

Historical freight modeling focused primarily on direct truck trips, but the dynamics of the mode choice and the supply chain aspects of freight movements have become critical for better understanding implications for planning. Advanced behavioral/agent-based freight models are now being developed that consider supply chain and delivery systems to provide a more complete understanding of freight movement and forecasting. While transportation planning agencies have begun developing advanced behavioral/agent-based freight forecasting models, existing literature and research is limited in scope and detail. The advent of Federal research into advanced freight models has provided an opportunity to collaborate across agencies and build new methodologies to address these challenges. This report describes the experiences with advanced supply chain freight travel demand modeling.

This project evaluated seven State and regional agencies and summarizes the scope and details of their behavioral-based supply chain freight models. These included all the behavioral-based supply chain freight models in the United States (models from Chicago, IL, Florida, Maryland, Portland, OR, Phoenix, AZ, Oregon, and Wisconsin). The reviews evaluated the methods used in terms of freight modeling needs, model structure, market segmentation, assumptions, performance measures, approach to forecasting, and types of applications. The reviews also identified data used for inputs, estimation, calibration, and validation along with any data that was desired but not available.

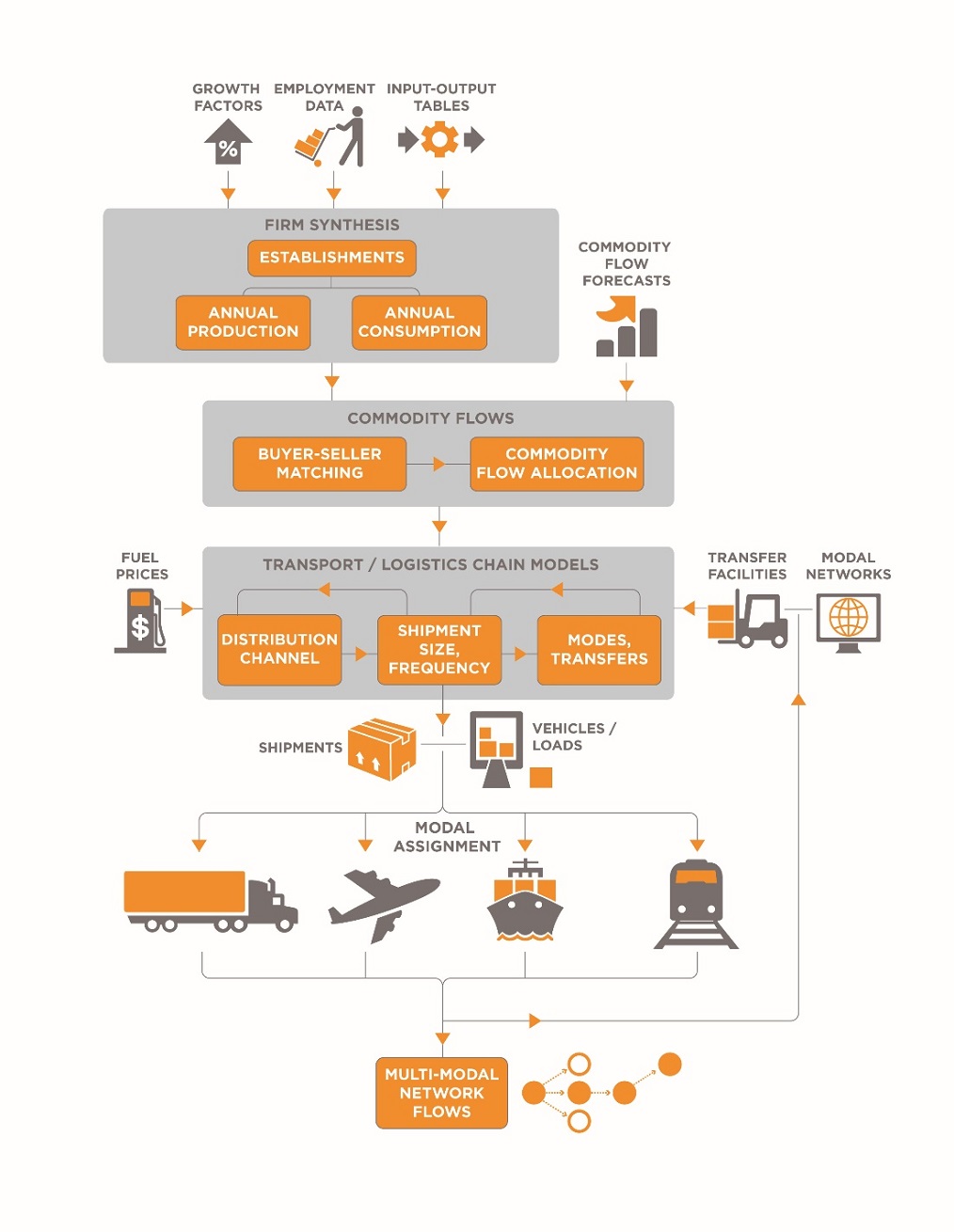

These advanced behavioral-based supply chain freight models are disaggregate models that incorporate supply chain procedures and truck touring aspects. The common components/approaches to advanced behavioral-based supply chain freight models are summarized below and illustrated on the following page:

- Firm synthesis includes freight production and consumption.

- Commodity flows include buyer-supplier matching and commodity flow allocation.

- Transportation/logistics include distribution channel, vehicle choice and shipment size.

- Modal assignment.

- Network flows include truck touring models.

Figure E-1. Behavioral Supply Chain Modeling Process.

Source: (RSG, University of Maryland, and Vision Engineering and Planning, 2017)

The elements of a freight model design rely on traditional multinomial and nested logit choice model formulations. The first step of these supply chain models is an enumeration of establishments based on iterative proportional fitting methods. The buyer-supplier matching model component is based on different methods, with the most advanced being a game theory application. Buyers consider several transportation, logistics, risk, capacity, and productivity factors for sellers when selecting a seller. Some buyer-supplier matching models use fuzzy logic or agent-based computational economics. Tour-based truck models primarily use the multinomial logit choice approach, combined with the traveling salesman problem algorithm. In several cases, the stop-sequencing element of the truck-touring models used a different approach, such as the greedy algorithm and the hurdle/count model.

Data is another vital element of a freight model. Limited availability of data on goods movement previously hampered freight models; however, recent sources of new data combined with new methods have allowed freight models to advance. There are national freight datasets that are publicly available to develop inputs to freight models in combination with State or regional data. New data sources collected from mobile or navigational systems have provided opportunities for calibration and validation of advanced freight models.

Technological advances associated with collecting business information have been exponential, leading to a massive increase in the amount of data that is generated, stored, and distributed. The internal and external sharing of data is crucial to most business operations. It forms the basis for most business decision-making processes and models. Conversely, the protection of these data, which are often proprietary in nature, is essential to reducing risk and liability and is a necessity for firms competing in a free market. Public transportation agencies can consider arrangements with private data firms or confidentiality agreements to obtain data needed for behavioral supply chain freight models while protecting data privacy.

Advanced behavioral/agent-based freight models provide improved tools to better understand supply chain decisions and the policy levers for improving freight mobility. This can provide critical data to support performance measures that evaluate freight policies and programs. Typical freight performance measures include tonnage or value of goods moved, cost per ton, import and export tonnage or value, modes shares, and market shares of international or domestic trade. Freight volumes, travel times, and speeds are important means of measuring performance of the system along with other measures for operations, finance, and safety.

An agency's decision to transition to a more advanced freight model structure must weigh the investment cost of transitioning against the importance of answering detailed policy and planning questions.