Best Practices for Road Weather Management

South Dakota DOT Maintenance Decision Support System

Transportation agencies, which are responsible for providing safe, reliable highways throughout the winter season, face significant challenges:

- Travelers and commercial carriers with demanding delivery schedules expect higher levels of service.

- Transportation agencies have limited funding and staff.

- Reliable site- and time-specific reports of road conditions can be hard to get.

- Some weather conditions—particularly fog, frost, and blowing snow—can be difficult to forecast.

- Capabilities and limitations of new and innovative maintenance treatments are not fully understood.

- Agencies are losing their most seasoned maintenance workers, who have experienced diverse weather and treated a lot of roads during their careers.

- Transportation agencies face environmental challenges to the types and amounts of deicing materials they apply.

During the period of 2002–2012, the South Dakota Department of Transportation led a multi-state pooled fund study that developed and extensively deployed a Maintenance Decision Support System (MDSS). The work is directed by a Technical Panel representing every participating state and the Federal Highway Administration and is administered by the South Dakota Department of Transportation’s Office of Research.

System Components: The premise behind MDSS is:

- if you know current road conditions;

- if you know the near- to medium-term weather forecast with confidence;

- if you understand and can model the chemistry and physics of road surfaces subjected to weather, traffic, and maintenance activities; and

- if you know available maintenance resources—equipment, materials, operators, and time;

- then MDSS can recommend sound winter maintenance strategies—treatments, application rates and timing—and predict the resulting road conditions. By analyzing available alternatives, MDSS recommends most cost-effective treatments.

Major MDSS components include:

-

a vendor supplied and operated information system that assimilates a wide variety of weather and maintenance data and models pavement surface response to weather, already applied maintenance treatments, and feasible future treatments;

-

a desktop graphical user interface customized to individual users, providing detailed information on weather and road surface conditions and predictions, as well as maintenance treatment recommendations;

-

on-vehicle systems data systems that inform the MDSS of weather conditions, road conditions, and applied maintenance treatments and then inform equipment operators of predicted conditions and maintenance recommendations.

-

System Operations: The MDSS incorporates the scientific framework and computational tools necessary to reliably recommend sound winter maintenance treatment strategies:

-

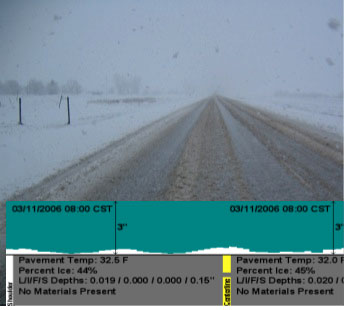

Report Current Road Surface Conditions—MDSS accepts observations of current road conditions from manual observations, on-truck instrumentation, and in-pavement sensors. If no observations are available, MDSS estimates the condition of the road surface on the basis of recent weather and reported maintenance.

-

Report Actual Maintenance Treatments—Maintenance treatments (plowing and chemical application) are reported by manual entry or automatically by instrumented snowplows.

-

Assess Past and Present Weather Conditions—MDSS not only considers current weather conditions—such as temperature, dew point, wind velocity and direction, precipitation type and rate, presence of blowing and drifting snow, cloud cover, and visibility—but also past conditions recent enough to affect the road surface.

-

Assess Present Roadway State—MDSS’s physical and chemical models of the pavement and the “active layer”—the mix of water, ice, chemical, and grit—predict temperature, moisture type and depth, and chemical concentration.

-

Predict Storm Event Weather— MDSS uses sophisticated ensembles of computer models, supplemented with input from live meteorologists, to make site- and time-specific weather predictions for four to six hours short-term, and up to twenty-four to thirty hours long-term.

-

Identify Feasible Maintenance Treatments—MDSS recognizes the specific constraints in equipment, materials, operating hours, and crew size that exist at each road segment, and only considers maintenance treatments that fall within those constraints.

-

Target Agency Priorities—MDSS considers the agency’s defined priorities regarding acceptable levels of service and the relative importance of a road segment compared to other segments.

-

Predict Road Surface Behavior—Physical and chemical models in MDSS predict the future behavior of the active layer for each of the feasible maintenance treatments. For each treatment—chemical application, plowing, or a combination of both—the models predict whether the road will become dry, wet, snowy, or icy during the next several hours. MDSS can make predictions about numerous deicing materials, including liquids, brines, and salt mixtures.

-

Communicate Recommendations to Supervisors and Workers—Finally, MDSS communicates treatment recommendations to truck operators or maintenance managers who direct fleet operations.

Transportation Outcome(s): Independent analysis of the benefits and costs of MDSS demonstrates potential for significant cost savings, improved service, or a combination of the two. A case study of New Hampshire’s five previous winters showed that, had MDSS been used, 23% less salt could have provided the same level of service; alternatively, the incidence of “unacceptable” driving conditions could have been reduced by 10–15% with equal salt use. In either case, the overall benefit/cost ratio was about 8:1. Similar case studies in Minnesota and Colorado showed smaller, but worthwhile, benefit/cost ratios.

Indiana’s statewide deployment of MDSS during the winter of 2008-2009 provides the most direct evidence of MDSS benefit. Using MDSS as a management tool, Indiana reduced salt costs by $12 million and realized more than $1M savings in fuel and overtime. Even after normalizing for winter conditions, Indiana estimated overall savings at $11 million, 27% of its normal total winter budget.

In addition to cost efficiency, MDSS users have realized other intangible but important benefits:

- “one-stop” convenience for complete winter weather information;

- better anticipation of storm events and resulting road conditions;

- delivery of weather forecasts and maintenance recommendations directly to snowplow operators;

- more consistent and seamless winter maintenance among maintenance units;

- reduced environmental exposure to deicing chemicals;

- use of the MDSS storm playback feature as a powerful maintenance training and analysis tool.

Implementation Issues: States in the MDSS Pooled Fund Study have achieved varying levels of deployment. Some states, especially those that joined the study early, have deployed extensively throughout their state highway systems. Others that joined the study more recently have established limited or pilot deployments. Deployment issues common to the states have included:

- adoption of new computer and communications technology

- user acceptance of a new winter maintenance paradigm

- developing technical expertise to support and use the technology effectively

- financial investments needed to deploy and operate the MDSS.

Contact(s):

- David L. Huft, Research Program Manager, 605-773-3358.

Reference(s):

- MDSS Pooled Fund Study Fact Sheet.

- Tony McClellan, P.E., Paul Boone, P.E., and Melody A. Coleman, 2009. Indiana DOT Statewide Deployment Report.

- Western Transportation Institute, Analysis of Maintenance Decision Support System (MDSS) Benefits & Costs, SDDOT Research Report SD2006-10-F, 2009.

Keywords: Winter Maintenance Decision Support.

previous | next