Measuring Border Delay and Crossing Times at the U.S.–Mexico Border—Part II

Step-by-Step Guidelines for Implementing a Radio Frequency Identification (RFID) System to Measure Border Crossing and Wait Times

OVERVIEW OF BORDER CROSSING PROCESS

Overview of the Commercial Vehicle Crossing Process at the U.S.–Mexico Border

The process for commercial freight to enter the United States from Mexico through border crossings begins at the Aduanas (i.e., Mexican customs) facility on the southern side of the border (also referred to as the Mexican export lot). After clearing customs on the Mexican side, a truck crosses a physical bridge or a short roadway segment to enter into the United States. Immediately upon entering the United States, the truck proceeds to the U.S. Federal inspection compound. Entrance to the compound is accessed through one or more primary inspection booths. At these primary inspection booths, CBP officers determine whether the truck requires secondary inspection and either direct the driver to it or instruct the driver to simply proceed to the exit of the inspection facility. For the FAST program, one or more lanes that allow cargo that meets specified security requirements to be expedited through the primary inspection process are provided. Final clearance to exit the inspection facility is given at one of the booths at the exit of the U.S. Federal inspection compound.

The Federal and State inspection facilities are usually connected by one or more lanes. After exiting the U.S. Federal inspection compound, trucks continue toward the State inspection facility. If present, weigh-in-motion sensors measure the weight of every truck that travels on this access road. Past the access road, trucks continue moving toward an inspection shed. Trucks continue moving through the inspection shed and are instructed to either proceed to the exit of the State facility or are told that they have been selected for secondary inspection. If they are selected for secondary inspection, trucks typically bear right after the inspection shed and loop back into the middle of the State inspection facility for further examination.

Basic Definitions of Border Crossing and Wait Times

While the collective term “travel time” has been used previously, it is useful to distinguish between the two main types of travel time to be measured through this project. Wait time is defined as “the time it takes, in minutes, for a vehicle to reach the CBP’s Primary Inspection booth after arriving at the end of the queue.”1 This queue length is variable and depends on traffic volumes and processing times at each of the inspection facilities throughout the border crossing process. Crossing time has the same beginning point in the flow as wait time, but its terminus is the departure point from the last compound that a vehicle transits in the border crossing process. As a metric, wait time is of greater significance than crossing time to CBP operations, whereas crossing time is of relatively greater interest to FHWA.

The remainder of this section is excerpted from the Part I Final Report (3). According to the report:

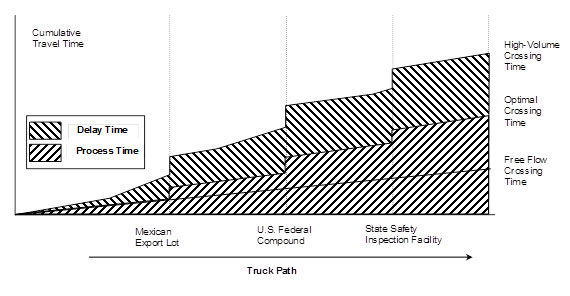

The delay associated with the border-crossing…can…be described in different ways. In 2002…a study was conducted for the Office of Freight Management and Operations of FHWA titled Evaluation of Travel Time Methods to Support Mobility Performance Monitoring. In that project, border delay was defined as the difference between actual crossing time and low-traffic-volume crossing time. With this definition, the processing time that the inspection agencies need to accomplish their mission was removed from the description of delay. Moreover, the authors mention that the use of free-flow conditions is a standard that is not relevant at border-crossings. The following graph describes the differences between the free-flow travel time, the optimal crossing time, and the high-volume crossing time.

Figure 1 illustrates these definitions.

The Part I Final Report further states:

As shown on the graph, the free-flow crossing time would be that where the truck would not have to stop at any time during the border-crossing trip. Obviously, this scenario is not realistic and therefore should not be set as a reference. The optimal crossing time is set as the base time, since it represents the case where there are no queues at any of the stops. This optimal crossing time is achieved under very low traffic volume conditions and takes into account the processing time at all inspection facilities. Finally, the high-volume crossing time accounts for all delays caused by high traffic volume that cause lower traffic speeds and queues.

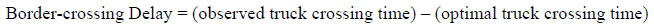

Taking these factors into consideration, it can be concluded that the border-crossing associated delay is determined by the difference between the observed crossing time and the optimal crossing time, or:

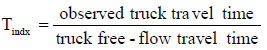

In order to have a better estimate of the status of the border-crossing time, a similar concept as the travel time index (Tindx) can be used. The Tindx is defined as follows:

For commercial border-crossings, as previously discussed, instead of using free-flow travel time, the crossing time under optimal conditions will be used to define the Border-crossing Time Index.

A very important fact that has to be taken in consideration is that not all trucks go through the same number of inspections. In most cases, a first inspection is enough to check the status of the shipment, the truck, and the driver. In some other instances, extra attention has to be given to a truck, its contents, or the driver. Moreover, most of the largest commercial border-crossings have dedicated FAST lanes, where crossing time might be significantly shorter since FAST expedites processing for commercial carriers who have completed background checks and fulfill certain eligibility requirements.

Therefore the truck population has to be divided into three categories:

- FAST shipments.

- Shipments that go through Primary Inspection only.

- Shipments that go through secondary inspection.

Border-crossing delay and Border-crossing Time Index will have to be estimated for each one of these three categories since all of them have different optimal crossing times. Depending on the technology, a different number of readers will be needed to identify these three types of trips ().

Factors That Influence Border Crossing and Wait Times

Crossing and wait times are influenced by a wide variety of factors. Some factors are related to operational changes related to Federal and State inspection processes, while others are external, such as approaching volume and major incidents around the border crossings. Influencing factors include the following:

- Time of day and day of week—Commercial vehicles crossing the border follow a temporal trend and show a distinct peak and off-peak volume. Intuitively, a temporal trend of crossing and wait times follows a similar trend for volumes.

- Approaching northbound volume—Volume of vehicles approaching the Federal inspection facility has a significant impact on crossing and wait times. Approaching volume of vehicles is also a function of time of day and week, special events and holidays, and other factors. The number of transponders read by the RFID readers on the Mexican side can be taken as a proxy to the approaching truck volume.

- Number of inspection lanes open—The number of inspection lanes open during any given time is correlated with crossing and wait times of vehicles. Vehicles that go through secondary inspection have much higher crossing times than the rest. However, it is not clear what percentage of total vehicles go through secondary inspection in a day. Also, the number of lanes used at the DPS facility influences the crossing and wait times of trucks.

- Shipment type—Depending on the type of shipment, crossing and wait times could vary significantly, especially the shipments that are empty and are enrolled in the FAST program.

- Type of commodities—Many POEs experience significantly higher crossing and wait time during seasons when particular agricultural products are imported into the United States from Mexico. Also, agricultural commodities have to go through screening not only by the CBP but also the U.S. Department of Agriculture as they enter the United States.

1 Border Wait Time Working Group presentation, April 2009, http://www.thetbwg.org/meetings/200904/1_-_border%20wait%20times%20update.ppt ↑