4.0 Concept of Operations

A virtual weigh station (VWS) is an enforcement facility that does not require continuous staffing and is monitored from another location. (Technology Deployment Challenges and Guidelines on the Use of Weigh-in-Motion in Roadside Enforcement, submitted by Cambridge Systematics to the Federal Highway Administration, April 2009, as part of the Truck Size and Weight Enforcement Technology Project, page 12.) The virtual weigh station concept is very flexible. While there is a minimum set of functionality/technology that must be deployed in association with a VWS, states can customize their VWS deployments to meet their specific functional needs (e.g., focus exclusively on truck size and weight issues, expand focus to include safety and credentialing regulations), operational environment (e.g., typical weather conditions, physical space, terrain), and communication infrastructure (e.g., presence of communication infrastructure at site, presence of power at site). This section documents the basic VWS concept, as well as additional functionality that can be associated with an expanded VWS.

4.1 Virtual Weigh Station Goals

Virtual weigh stations are employed to meet a wide range of operational objectives. States typically deploy virtual weigh stations in order to:

- Increase compliance with Federal and State size and weight standards through augmented enforcement operations (e.g., screening commercial vehicles; persistent enforcement operations on known bypass routes around fixed facilities; persistent enforcement operations on routes that are not regularly patrolled by mobile enforcement assets due to remoteness/geography/topography);

- Improve commercial vehicle safety through targeted enforcement at commercial vehicles that are known to be overweight, are improperly credentialed, or are operated by high-risk motor carriers;

- Improve the efficiency and effectiveness of roadside enforcement assets;

- Improve resource allocation and staffing decisions through the use of information; and

- Reduce costs associated with the expansion of commercial vehicle size and weight/safety enforcement programs through the use of technology.

As states consider the next generation of roadside technologies, VWS sites also may be designed to serve as conduits for two-way communication between the roadside and a vehicle in motion and therefore may support a broader range of safety, security, mobility, and systems management objectives.

4.2 Functions of Virtual Weigh Stations

As noted above, virtual weigh stations can be designed and implemented to support a wide variety of roadside enforcement functions. At a minimum, a VWS must support the following functionality:

- Real-time weighing of a commercial vehicle—Determine a commercial vehicle’s approximate axle weights as the vehicle moves across sensors, and calculate the gross vehicle weight and classification based on the number of axles, as well as axle weights and spacings;

- Real-time identification of a commercial vehicle—Identify accurately all commercial vehicles that pass the site;

- Integration of real-time data for screening decisions—Integrate commercial vehicle identification and weight data in real-time/near real-time, in order to support manual (i.e., decisions made by roadside enforcement personnel) or automated (i.e., decisions calculated by the system and then forwarded to a human) targeting of specific commercial vehicles for further enforcement action; and

- Communication of data to enforcement personnel in real-time—Communicate VWS data (e.g., vehicle photo, weight data) to authorized users (e.g., mobile enforcement personnel stationed downstream from the VWS, enforcement personnel stationed at a fixed inspection site that could be dispatched to intercept an overweight vehicle) in a timely and secure manner.

States also use their current VWS deployments to support the following expanded functionality:

- Real-time identification of the motor carrier responsible for the operations of a commercial vehicle—Identify the motor carrier that is responsible for the safe operation of the vehicle;

- Implementation of an expanded screening algorithm—Integrate additional criteria (e.g., motor carrier history of safety performance, motor carrier history of compliance with size and weight standards, current commercial vehicle credential status, current motor carrier credential/operating authority status, driver’s license status) into the screening decision;

- Real-time verification of vehicle dimensions—Integrate additional sensors (e.g., gantry-mounted laser overheight detectors) to determine if a commercial vehicle exceeds legal height, width, and length regulations and therefore would require an oversize/overweight permit; and

- Availability of data to support resource planning—Provide commercial vehicle average daily trip data (e.g., volume, weight, vehicle classification) in order to support the scheduling of mobile enforcement activities, as well as to identify locations in need of fixed enforcement facilities.

During recent stakeholder discussions about the future uses of roadside technologies, stakeholders also identified a series of additional functionality that could be supported by a VWS. This additional functionality includes:

- Real-time identification of the commercial driver operating a commercial vehicle and inclusion of driver information in the screening decision—Identify the individual driving a commercial vehicle and determine if that individual can legally operate the vehicle at that time (i.e., commercial driver’s license is not revoked or suspended);

- Direct enforcement—Write a citation or take other enforcement action (e.g., prevent a commercial vehicle from being started) based on data from a VWS;

- Communication of real-time operational data to system managers—Serve as a conduit for onboard vehicle data (e.g., speed, windshield wipers on/off, air temperature) to be sent to traffic management centers in support of traffic/congestion monitoring and development of travel advisories;

- Communication of real-time traveler information to commercial drivers—Serve as the means by which real-time traffic (e.g., incident warning, congestion, weather advisories) and truck parking (e.g., location, availability) information could be delivered to commercial vehicle drivers operating within a specific geographic area/corridor; and

- Communication of commercial vehicle location data to authorized users—Accurately capture vehicle location data (i.e., date and time that it passed a VWS) in order to support private sector (i.e., asset tracking, estimated time of arrival [ETA] updates to vehicle’s motor carrier/shipper/receiver) and public sector (i.e., tracking of hazardous material by Department of Homeland Security, tracking of in-bond agricultural shipments by the United States Department of Agriculture) applications.

4.3 Key Concepts

The basic virtual weigh station functionality is based on the following concepts:

- Use roadside technology to augment human enforcement resources;

- Deploy scarce enforcement resources as effectively and efficiently as possible;

- Accurately identify all commercial vehicles in real-time;

- Determine a commercial vehicle’s weight to a degree of accuracy that is sufficient for its functional purpose (e.g., 10 - 15 percent error tolerance for system monitoring while building knowledge on system-level loadings; 3 - 5 percent error tolerance for mainline WIM systems for screening; 1 - 2 percent error tolerance for ramp WIM for sorting at weigh stations);

- Deliver the vehicle identification and weight data to enforcement personnel in real-time;

- Leverage other safety and credentialing data in screening criteria;

- Focus enforcement on commercial vehicles that pose the highest risk; and

- Deploy VWS technology in an open and expandable way so that future technologies (e.g., enhanced vehicle identification systems, driver identification systems, Smart Roadside, IntelliDrive/Commercial Vehicle Infrastructure Integration) can be integrated easily and cost effectively.

4.4 Operational Scenarios

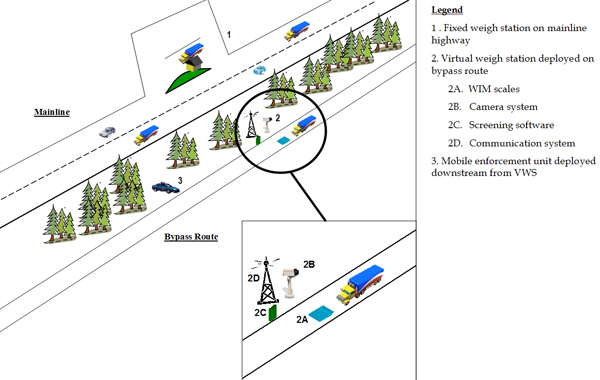

Varying technology is required to support the different types of VWS functionality (documented in Section 4.2). The minimum VWS functionality requires deployment of:

- WIM scales or sensors, which weigh the commercial vehicle;

- Camera (digital imaging) system, which captures real-time images of a commercial vehicle crossing the WIM system to support its immediate identification by enforcement personnel;

- Screening software, which integrates the data from the WIM and imaging systems; and

- Communication infrastructure, which makes the VWS data (e.g., vehicle photo, weight data) available to authorized users (e.g., mobile enforcement personnel stationed downstream from the VWS, enforcement personnel stationed at a fixed inspection site that could be dispatched to intercept an overweight vehicle) in a timely and secure manner. The VWS allows for the use of a variety of communication technologies. Depending on what is available at the site, authorized personnel may use a wireless connection (e.g., cellular, satellite) or a wired connection (e.g., fiber optics, T-1 line) to a secure Internet site to access the information.

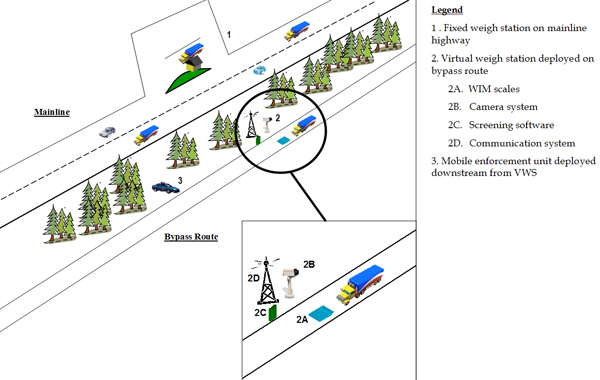

The following types of technology also may be deployed in order to support additional VWS functionality:

- License plate reader (LPR) and/or USDOT number reader system, which takes an image of the vehicle’s license plate or side of the commercial vehicle and uses OCR software to generate an electronic value of the vehicle’s license plate or USDOT number, respectively;

- Commercial Vehicle Information Exchange Window (CVIEW) or an equivalent, which provides real-time access to motor carrier safety (e.g., out-of-service [OOS] orders, safety algorithm scores) and credentials (e.g., operating authority, Unified Carrier Registration [UCR], International Fuel Tax Agreement [IFTA]) data, as well as commercial vehicle safety (e.g., past inspection reports) and credentials (e.g., International Registration Plan [IRP], oversize/overweight [OS/OW] permits, intrastate vehicle registration) data. This repository also could contain commercial driver’s license data for use in the screening process;

- State-issued permit compliance, which accesses on-board information in order to verify a permit has been obtained and is in valid operation when oversize or overweight elements are detected. Verification that the vehicle is operating on an “approved route” and at a legal time and within the limits provided for on the State-issued permit can be conducted at highway speed with proper information added to a transponder or radio frequency identification-based device, or through the real-time accessing of permit data stored in back-office safety and credentialing systems (i.e., CVIEW, OS/OW permitting system);

- Repository of past weight performance, which provides real-time access to a motor carrier’s and/or commercial vehicle’s previous compliance record with Federal and/or State truck size and weight limits;

- Driver identification system, which provides an electronic means to accurately identify the operator of a commercial vehicle while the vehicle is in motion;

- Augmented WIM scales, which enhances the accuracy in the weighing of the commercial vehicle, in order to support more reliable screening and ramp sorting enforcement operations; and

- Two-way communication, which provides the ability to share data from the commercial vehicle (e.g., speed, windshield wiper on/off, temperature) to the roadside, as well as from the roadside to the commercial vehicle (e.g., traveler information, truck parking information).

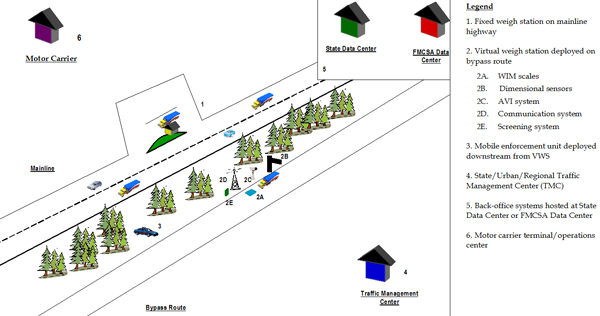

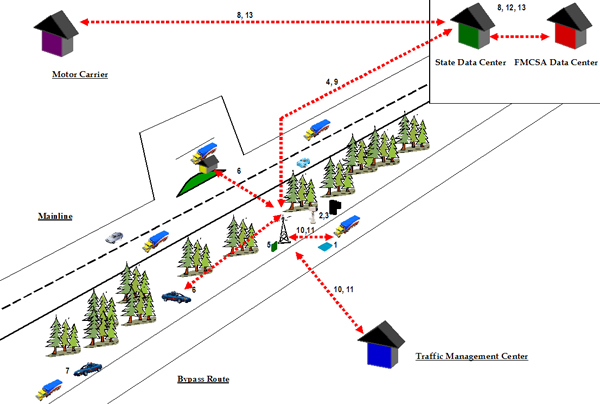

Figure 4.1 illustrates a typical layout of a basic VWS. Figure 4.2 illustrates the potential layout of a more robust VWS. To illustrate how operations of the basic VWS and a more robust VWS may differ, an operational scenario for each is detailed following the layout illustrations.

Figure 4.1 Basic Virtual Weigh Station Physical Layout

Figure 4.2 Expanded Virtual Weigh Station Physical Layout

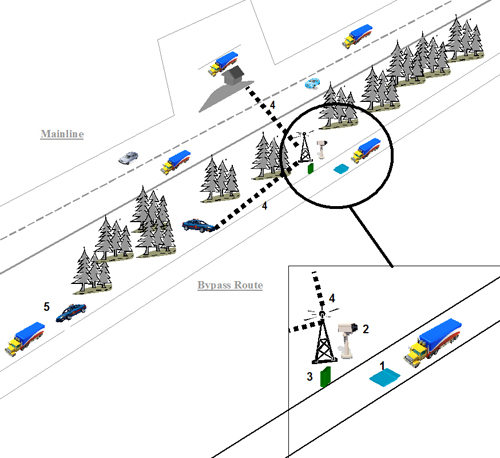

Basic VWS Operational Scenario

As illustrated in Figure 4.3, the following five steps summarize the typical operations of VWS:

- As a commercial vehicle approaches the virtual weigh station, it is weighed while in motion on the WIM scales.

- A picture of the commercial vehicle is taken for identification purposes.

- Screening software integrates data from the WIM and camera system.

- Mobile enforcement officer positioned downstream from the VWS accesses the VWS data (e.g., photo of commercial vehicle, WIM data) and makes a screening decision. Enforcement personnel at the fixed site access the VWS data (e.g., photo of commercial vehicle, WIM data) and make a screening decision.

- Overweight commercial vehicle is intercepted for weighing/inspection.

Figure 4.3 Basic Virtual Weigh Station Concept of Operations

Expanded VWS Operational Scenario

As illustrated in Figure 4.4, the following 13 steps summarize the potential operations of a VWS in the future:

- As a commercial vehicle approaches the virtual weigh station, it is weighed on the WIM scales and measured by dimensional sensors.

- AVI system automatically identifies the specific vehicle.

- License plate/USDOT number reader and associated optical character recognition (OCR) software identify the motor carrier that is responsible for operating the commercial vehicle.

- Screening system uses vehicle identifier and motor carrier identifier to query back-office safety, credentials, and weight performance data. (NOTE: These data may be stored in a single repository, such as a State’s Commercial Vehicle Information Exchange Window [CVIEW], or in separate repositories.)

- Screening system integrates weight data with safety, credentials, and weight data in order to determine whether a commercial vehicle should be targeted for additional enforcement actions.

- Mobile enforcement officer positioned downstream from the VWS and/or enforcement personnel stationed at a fixed site access the VWS system (e.g., photo of commercial vehicle, vehicle identifier(s), WIM data, screening decision).

- A commercial vehicle/motor carrier that is overweight or noncompliant with safety (e.g., out-of-service order) or credential (e.g., IRP, IFTA, UCR, OS/OW) is intercepted for weighing/inspection. If monitoring is conducted at the fixed site, an officer is dispatched to locate and pull the vehicle over for weighing/inspection, or direct the vehicle to the weigh station for weighing/inspection.

- If human resources are unable to intercept the vehicle, a warning letter or a citation could be generated by a back-office process and forwarded to the motor carrier identified by the USDOT reader. The concept of issuing warning letters to motor carriers that are routinely noncompliant is consistent with FMCSA’s new operational model (Comprehensive Safety Analysis for 2010 {CSA 2010]) that places a greater emphasis on more frequent interactions with motor carriers.

- Vehicle, motor carrier, and commercial driver identifiers, as well as compliance (i.e., weight, safety, credential) data are sent to a back-office repository so the State can develop a history of compliance/noncompliance with weight standards for each motor carrier and/or commercial vehicle (similar to the safety performance metrics calculated by FMCSA).

- Weather data from the vehicle is sent to system operators for real-time traffic management.

- Localized and real-time traveler information is sent to the commercial vehicle for integration with on-board systems designed to display this information safely and with a minimum amount of driver distraction.

- Data from the VWS is available to authorized users for planning and reporting purposes.

- Data from the VWS is available to motor carrier users for tracking of the company’s assets and their performance.

Figure 4.4 Expanded Virtual Weigh Station Concept of Operations

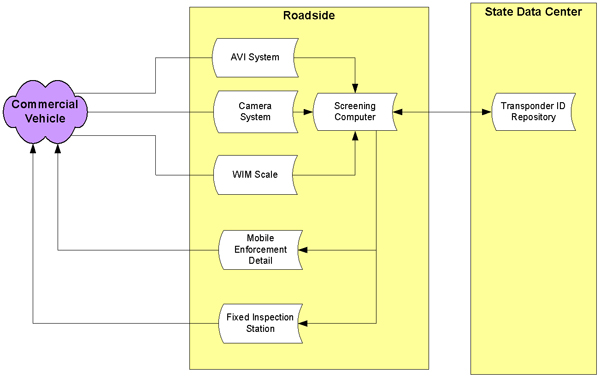

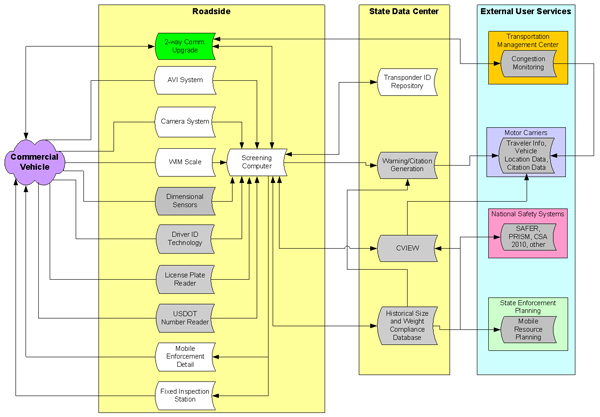

4.5 Architecture

Figures 4.5 and 4.6 provide high-level overviews of the proposed system architecture for basic and expanded VWS systems. The basic VWS architecture in Figure 4.5 includes two groupings – one for Roadside technology components and another consisting of back-office components grouped into a State Data Center. The expanded VWS architecture in Figure 4.6 adds a third grouping called External User Services, which provide for additional VWS operations/support capabilities for external users. These three architecture groupings are further defined as follows:

- Roadside—This grouping includes the set of technologies and operations that involve the identification, observation, and enforcement interaction with the commercial vehicle and the driver. Baseline core VWS technologies include AVI transponder vehicle identification, camera systems, and WIM scales. Expanded VWS roadside technologies include driver identification technologies (e.g., biometrics, smart cards), OCR systems (e.g., LPRs and USDOT number readers), and dimensional sensors.

- State Data Center—This grouping provides the set of information technology systems and databases that enable the functionality of the VWS system. The State Data Center referenced in the context of this ConOps is a multi-agency data system fusing information stores maintained by Departments of Transportation or Highway Agencies, Departments of Motor Vehicles, State Enforcement Agencies, and State Revenue Agencies supporting high-speed information exchanges at roadside enforcement sites. In the basic VWS scenario, only a repository of transponder identifiers would be hosted in the State Data Center. Expanded VWS functionality is largely based on the increased amount of data/factors that can be queried at the roadside and/or stored from the roadside. As such, the expanded VWS scenario has several additional components that would be hosted at a State Data Center, including:

- CVIEW—repository of motor carrier, commercial vehicle, and commercial driver safety and credential information that can be queried to support the real-time screening at the roadside. CVIEW also could store wireless roadside inspection data that is collected from a VWS. CVIEW also serves as the conduit to exchange data to/from other jurisdictions and FMCSA. For instance, CVIEW is the means by which a State gains access to FMCSA’s screening algorithm data, as well as other states’ IRP and IFTA status information. Many State CVIEWs also store other commercial vehicle credentials (e.g., OS/OW permit, intrastate vehicle registration) that can be accessed in real-time at the roadside;

- Warning/citation generation—back-office process that could generate warning letters and/or citations to a motor carrier if a commercial vehicle is found to be noncompliant by a VWS; and

- Historical size and weight compliance database—back-office application that records a motor carrier’s long-term compliance with Federal and State size and weight regulations, in order to support planning activities, as well as development of warning letters.

- External User Services—This grouping encompasses future potential uses of VWS information to support public and private sector operations. Motor carriers would be provided with time-stamped vehicle location information that could support enhanced productivity, as well as tailored traveler information. Transportation management centers would receive tailored information concerning roadway congestion and conditions. Through CVIEW, State and Federal safety systems would receive key enforcement data outputs. State enforcement agencies would also receive key statistical information that could assist them in better planning for VWS deployment across a State.

The arrows connecting each of the components in Figures 4.5 and 4.6 illustrate the specific information interfaces for the VWS architecture. In general, the Roadside elements identify and weigh the commercial vehicle, as well as conduct enforcement activities. The screening computer integrates data from the Roadside systems and vehicle and uses this data to query (in the expanded scenario) data from the State Data Center in order to screen and target vehicles at the roadside. The screening computer also relays the data from the commercial vehicle and Roadside elements to enforcement personnel stationed at a fixed site or in a mobile unit. These enforcement personnel conduct roadside enforcement activities on targeted vehicles.

In addition to providing data to be queried by the screening computer, the State Data Center systems also provide the outputs necessary to support the External Users of the VWS data (e.g., traffic management centers, motor carriers, Federal safety systems, planning offices). State Data systems also could generate automatic citations and record a motor carrier’s historical compliance with size and weight regulations. In this construct, at a point in the future, two-way communication also could facilitate actual communication between the truck and back-office and External User systems.

Boxes shown in white are components of the basic VWS concept. Boxes shown in gray are components of the expanded VWS concept. The box shown in green is indicative of a future system (e.g., 5.9 GHz) that could support two-way communication between a commercial vehicle and back-office systems.

Figure 4.5 Basic Virtual Weigh Station Interfaces

Figure 4.6 Expanded Virtual Weigh Station Interfaces

4.6 Common Steps

There are five basic steps that are shared between the two operational scenarios:

Identify commercial vehicle—An accurate and timely identification of the commercial vehicle is at the core of all VWS functionality. The vehicle identification ensures that the proper vehicle is screened and/or targeted for additional enforcement activities. Most states that have augmented the basic camera system with AVI functionality currently are using LPRs to identify commercial vehicles. Performance of LPRs has been uneven and remains under investigation. Some states have reported LPR accuracy rates of 85 percent while others have reported rates as low as 30 – 50 percent. A variety of operational (e.g., speed, placement of license plate, ink used on license plate) and environmental (e.g., shadows, glare, weather) issues directly impact the effectiveness of these systems. Concerned about the long-term viability of LPRs as the identification technology, some states have begun to investigate alternate detection systems for use in their roadside enforcement systems. For instance, New York is investigating the use of 5.9 GHz (IntelliDrive/Vehicle Infrastructure Integration [VII]) technology, and Tennessee is studying the use of a cellular/satellite communication system. Other applications (e.g., tolls) also have begun to migrate towards inexpensive passive (“sticker”) tags that are affixed to vehicle windshields. FHWA is initiating a new project to identify which technology is best suited to attain its long-term objective of identifying all commercial vehicles in real-time at highway speeds.

Weigh commercial vehicle—Like vehicle identification, accurately weighing a commercial vehicle is a core component of any VWS. The accuracy of the gross vehicle weight or axle weight estimate can be affected by the WIM scale technology in use. When installed on the mainline, more expensive WIM systems have less variance in their readings and may better compensate for filtering external factors that affect vehicle weight calculations. Conversely, less expensive WIM scales or sensors may not be as accurate at highway speed. An example of a low-cost WIM device that has been deployed in the United States is the piezoelectric sensor. More recently, several states have begun including quartz piezo WIM systems in their programs because of the acceptable level of accuracy these sensors produce. Quartz piezo WIM devices, like electric piezos, are relatively inexpensive and not difficult to install but feature a short service life, especially on routes with high truck volumes. More expensive systems like load cell and bending plate offer higher accuracy in weight estimates but are more expensive to procure and are significantly more intrusive to the pavement structure. Bending plate systems offer high accuracy but are quite difficult to maintain; their expected service life far outperforms piezo sensors. Load cell scales are very durable, feature a significantly longer service life than the other devices, if maintained properly, and are quite easy to maintain. The trade-off among “up-front cost,” expected service life, and ease of maintenance should be carefully worked through before procurements take place. Typically, accuracy rates for all of these devices range from 85 to 97 percent.

Establish vehicle dimensions—Another aspect of truck enforcement is measuring the vehicle dimensions to determine compliance with length, width, or State-specific height requirements. Verification of vehicle dimensions for State-issued oversize permit compliance can be automated by deploying overhead gantry or roadside elevated laser scanning systems. Many commercial vendors have vehicle dimension technology bundled into their “off-the-shelf” virtual weigh station packages. The military has had vehicle dimension detection systems in operation for quite some time now to support rapid deployments. Recently, more advanced laser-based systems have been emerging, offering enhanced image quality and greater accuracy in determining vehicle envelopes.

Determine screening decision—If a VWS is designed to support a manual screening model, the system simply delivers a photo of the vehicle and accurate weight information to a roadside enforcement resource in real-time. The system also may use color (i.e., a red border around the photo, red text for overweight data) to highlight an overweight vehicle. If a VWS is designed to automatically screen commercial vehicles based on a series of criteria (e.g., weight, safety algorithms, past compliance with size and weight standards), the screening software must be programmed to weigh the various criteria and determine what factor or combination of factors will yield a decision to target a commercial vehicle for further scrutiny. A similar approach (e.g., pre-determined weights are assigned to specific evaluation criteria with the sum total of the criteria yielding a pull-in/bypass decision) is used to support electronic screening in some states.

Share data—Conceptually, a VWS is designed to take data from a commercial vehicle and share it with authorized users. In the basic VWS concept, only vehicle identification (either via a transponder or a photo) and weight data is shared and enforcement personnel are the only authorized personnel authorized to access this data. In the expanded VWS concept, a larger amount of data is shared between the commercial vehicle and the roadside and a broader range of authorized users can access specific types of data. The expanded data being shared from the commercial vehicle includes vehicle identification via OCR, driver identification, weather data, and operational data. Further with the expanded VWS concept, data also may be shared from the roadside (e.g., truck parking information, traffic/traveler advisories) to the commercial vehicle and from back-office systems to the motor carrier (e.g., tracking data, citation data). Regardless of the type or amount of data being shared, the VWS concept provides a platform that serves as a conduit for information sharing.

4.7 Operational Policies

While VWS deployments vary widely by states, the following policies summarize the minimum policies that should be enacted by all states deploying VWS technology:

- All commercial vehicles must be identified and weighed by a VWS;

- Commercial vehicles should be allowed to proceed at the normal speed for the road on which they are operating when passing a VWS;

- Deployment of VWS technology should be designed to limit driver distraction;

- VWS deployments should leverage existing information technology (IT) and data infrastructure and standards (e.g., a State’s CVISN systems, existing WIM deployments) whenever possible;

- Motor carriers should be made aware of how data collected by a VWS will be used;

- Access to VWS data should be limited to authorized users that have a clear and pertinent business need for the information (e.g., roadside enforcement personnel to support screening decisions, motor carriers to track their own vehicles);

- Motor carriers should be provided with a means to challenge any data that they believe to be inaccurate;

- Direct enforcement and/or a change to a motor carrier’s safety rating will occur only if the VWS data (e.g., motor carrier/vehicle identification, weight information) can be certified as being accurate;

- Standards should be developed to govern the storage and retention (e.g., how long will data be kept) of all data associated with VWS deployments; and

- Data used by government agencies for non-enforcement purposes (e.g., planning) should be anonymous.

4.8 Impacts

Deployment of VWS technology has the potential to fundamentally change the way truck size and weight standards and regulations are enforced in the United States. Anticipated impacts include:

- All commercial vehicles subject to electronic screening—Current deployments of electronic screening are voluntary in nature (i.e., motor carriers determine if they wish to participate and thereby install a transponder). VWS deployments are designed to enable the screening of all commercial vehicles. This “100 percent” screening would be attained by the reading of identifiers that all commercial vehicles are required to have (i.e., license plate, USDOT number) or through the adoption of a new technology that all commercial vehicles would be required to install. With respect to current identifiers, additional research and refinement of technology are required to achieve 100 percent accuracy in reading commercial vehicles.

- Improved operational efficiency for enforcement personnel—VWS technology has the potential to dramatically improve the efficiency and effectiveness of the nation’s size and weight enforcement regime. Currently, less than one percent of commercial vehicles that are weighed at the roadside are found to be overweight. While this is in part a testimony to the number of legal carriers operating in the United States, it also is an indication that noncompliant carriers are successful in bypassing enforcement activities. VWS deployments will allow roadside enforcement personnel to target their efforts at commercial vehicles that are known to be operating over legal limits and allow compliant carriers to avoid roadside enforcement stops. VWS deployments also have the potential to exponentially expand the geographic scope of a State’s enforcement program and limit the number of routes on which a noncompliant vehicle can operate without being detected and/or monitored by enforcement personnel. This improved efficiency is a key factor in states’ decisions to deploy VWS technology, especially given the budget constraints under which many states currently are operating.

- More frequent verification of commercial vehicle compliance—The use of automated systems will allow for the frequent verification of commercial vehicle compliance with Federal and State size and weight regulations, as well as safety and credentialing regulations (if expanded VWS functionality is deployed). These more frequent inspections will be enabled by the deployment of enforcement assets (i.e., VWS) on bypass roads and in remote/urban areas that currently cannot accommodate roadside enforcement actions. More frequent inspections also will be supported by the 24X7 operational nature of VWS, as opposed to the shift deployments associated with human assets. Expanded VWS functionality (i.e., maintenance of a historical size and weight compliance database, issuance of warning letters/citations, targeting of motor carriers that regularly operate beyond legal limits) also will improve motor carrier compliance even in cases where enforcement personnel cannot be dispatched to execute a roadside inspection based on VWS data. Enforcement interventions (e.g., warning letters, company visits, inspections) also could be utilized on noncompliant carriers that cannot be addressed in real-time when fixed inspection sites become occasionally overwhelmed by commercial vehicle traffic, which likely will happen even if 100 percent of commercial vehicles could be identified electronically.

- Improved mobility for compliant motor carriers—VWS technology will continually verify the compliance of all commercial vehicles with Federal and State regulations but only target enforcement resources at high-risk motor carriers and commercial vehicles. This robust targeting will ensure that compliant commercial vehicles will avoid being stopped for a roadside inspection even though their compliance with Federal and State regulations will frequently be checked. The targeting will save time and money for compliant carriers while disproportionately delaying unsafe and noncompliant carriers, which should encourage compliance and ensure that noncompliant carriers do not enjoy an operational advantage over compliant carriers.

- Greater geographic enforcement coverage from limited financial resources—Many states continue to struggle with deep budget crises that are requiring them to seek alternate and more cost-effective means of doing business. Deployment of VWS has the potential to improve the efficiency of states’ roadside enforcement programs while reducing the costs associated with the deployment and operation of roadside assets.

- Development and maintenance of new data interfaces—The greatest benefits from VWS technology will be achieved through the deployment of expanded VWS functionality that will leverage deployments to monitor compliance with both size/weight and safety/credentialing regulations. In order to support this expanded functionality, interfaces must be developed and maintained from the roadside to the State’s CVISN architecture. CVISN is a national initiative designed to share safety and credentialing information across jurisdictional boundaries; it provides a rich repository of safety and credentialing data for the screening of commercial vehicles and targeting of high-risk commercial vehicles and motor carriers. Other Federal programs (e.g., Performance and Registration Information Systems Management [PRISM], Comprehensive Safety Analysis for 2010 [CSA 2010]) also can provide data to support the real-time screening of commercial vehicles. A forum to discuss these interfaces is provided through FMCSA’s Expanded CVISN Roadside Identification Ad Hoc Team, in which FHWA, states, industry, and other parties also participate.

- Development of new targeting data—Numerous targeting resources (e.g., ISS, PRISM, Safety Status Measurement System [SafeStat], CVIEW) exist to focus enforcement resources on carriers with poor histories of safety performance and/or noncompliance with credentialing regulations. At this point, there is no similar electronic repository of past performance data for a carrier’s compliance with Federal and State size and weight issues and as such, resources cannot be targeted at commercial vehicles operated by motor carriers that routinely operate overweight. FHWA and FMCSA could discuss the possibility to leverage the existing CVISN architecture to provide this information. Similarly, one of the new Behavioral Analysis Safety Improvement Categories (BASICs)—Improper Loading/Cargo—that will be at the core of FMCSA’s CSA 2010 program may provide a means to target enforcement resources at carriers that are routinely noncompliant with size and weight standards.

previous | next

|