Comprehensive Truck Size and Weight Limits Study - Compliance Comparative Analysis Technical Report

Chapter 2: Compliance Estimation of Enforcement Cost

2.1 Scope

This chapter documents the results from the estimation of cost of enforcement analysis performed as part of this compliance study. The purpose of this study is to assess the cost of enforcing truck size and weight (TSW) limits for trucks currently operating at or below current Federal truck weight limits as compared with a set of alternative truck configurations in six scenarios. It also estimates the enforcement cost impacts of introducing the alternative truck configurations into the traffic stream. To accomplish this, the objectives of the work are to:

- Document steps and procedures for the principal TSW enforcement methods used in North America, including the application and costs of technological components and systems;

- Gather and analyze truck enforcement program costs and resources (referred to as program inputs) at a national scale;

- Compare truck size and weight enforcement costs for States where trucks are authorized to operate above Federal limits with similar costs for States that adopt Federal truck weight limits; and

- Determine and compare the costs of weighing the alternative truck configurations and estimate the scenario cost impacts.

The scope of analysis for this work is constrained as follows:

- The base analysis year for the study is 2011. To capture annual trends in enforcement program costs, the analysis examines data reflecting program resources and activities from 2008 through 2012, inclusive, thereby using the most current, reliable data available.

- While the work focuses on TSW enforcement costs, much of the available cost data reflects the allocation of resources for both TSW and commercial vehicle safety enforcement. The costs reported by States reflect resources (e.g., personnel, facilities) directed at TSW enforcement and truck safety enforcement. No attempt has been made to disaggregate costs allocated to these separate programs.

- This work analyzes resources directed at enforcing truck size and weight. However, to support the purpose of this work, certain aspects of the analysis focus solely on truck weight.

- The work supports the comparative analysis of commercial motor vehicles that operate at or below an 80,000 lb. gross vehicle weight, a 20,000 lb. single-axle weight; a 34,000 lb. tandem axle weight ,and at or below weight limits as calculated through the Federal Bridge Formula as such limits are provided in Title 23 of the United States Code under Section 127. Per the legislation, vehicles that are exempted from the size and weight limits stated and provided in 23 USC Section 127 are to be treated as “vehicles operating in excess of federal size and weight limits.” Vehicles operating under a State-issued permit, including all divisible or non-divisible load movements, are to be treated in the same manner.

2.2 Methodology

As described in Chapter 1, enforcement program costs are considered inputs in the performance-based approach applied in this study. Within the context of this approach, this section provides specific details about the methodology and data applied for three of the four objectives. The methodology applied in this work extends the results of the previous 2000 CTSW Study in three main ways:

- It provides an updated and more comprehensive description of TSW enforcement methods and technologies. (The methodology used to achieve this objective is relatively straightforward, so no details are provided here.)

- It provides a more detailed analysis of the costs of enforcement at the national level, including an investigation of recent cost trends.

- It includes a comparative analysis of how costs may be impacted by the introduction of alternative truck configurations into the traffic stream. This type of analysis was not conducted as part of the previous 2000 CTSW Study.

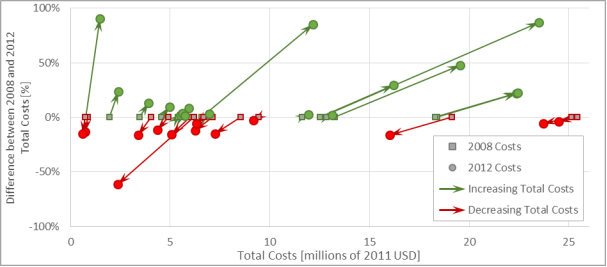

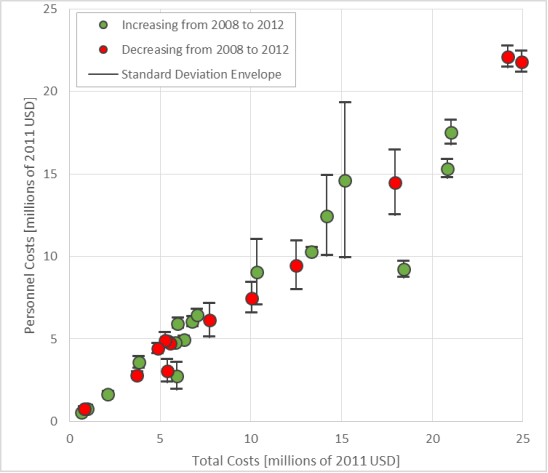

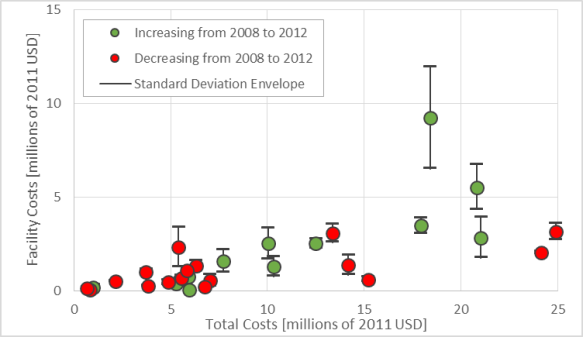

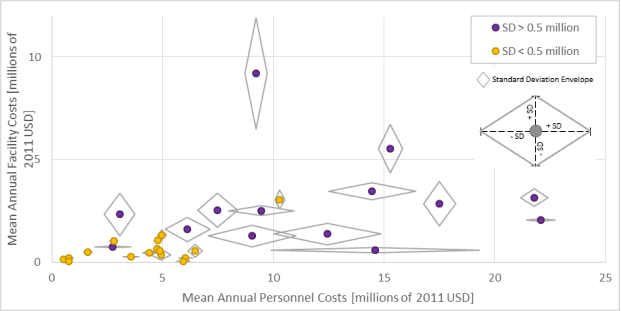

National-Level Trends

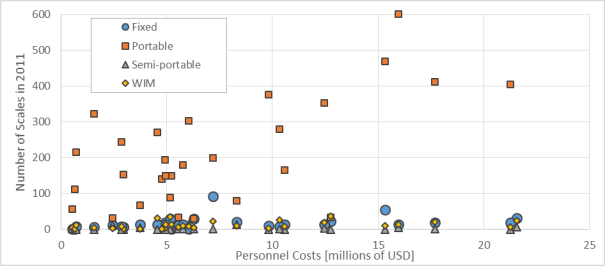

The measures of input included in the analysis of national-level trends are program cost (disaggregated into costs for personnel and facilities) and the number and type of weigh scales used to enforce truck weights, including WIM sites used for screening truck weights. State Enforcement Plans (SEPs), which are submitted annually by States to the FHWA, provide the primary source data for the analysis of enforcement costs and resources. The USDOT study team analyzed tabulated summaries for key metrics from 2008 to 2012 (i.e., total costs, facilities costs, personnel costs, quantity of weigh scale equipment). The following limitations apply to the data:

- The costs reported in the SEPs reflect those costs for truck size, weight, and safety enforcement. In most States, these programs overlap considerably—both personnel and facilities resources may be used to enforce size and weight limits and conduct vehicle safety inspections—and so no attempt was made to disaggregate costs allocated to these separate programs.

- The costs reported in the SEPs reflect those costs deemed by the State to be directed at enforcement activities in that State each year. For the most part, specific States show consistent cost trends over time; however, costs for certain States exhibit anomalies when major capital expenditures (e.g., for new enforcement facilities) are undertaken in a particular year.

- The SEPs do not contain any systematically reported information about TSW enforcement costs for specific vehicle configurations, routes, networks, industries, commodities, or permitted versus non-permitted trucks.

- It appears that certain States may be reporting the actual number of portable scales in operation while others may be reporting the number of locations at which portable scales are used or even the number of weighings conducted with portable scales.

State-Level Comparative Analysis

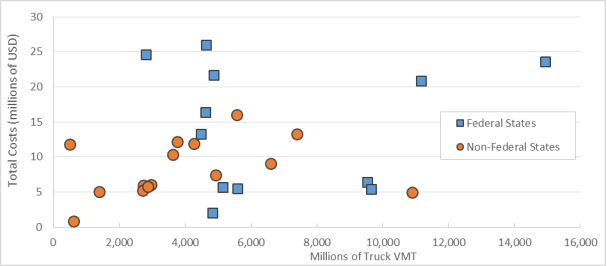

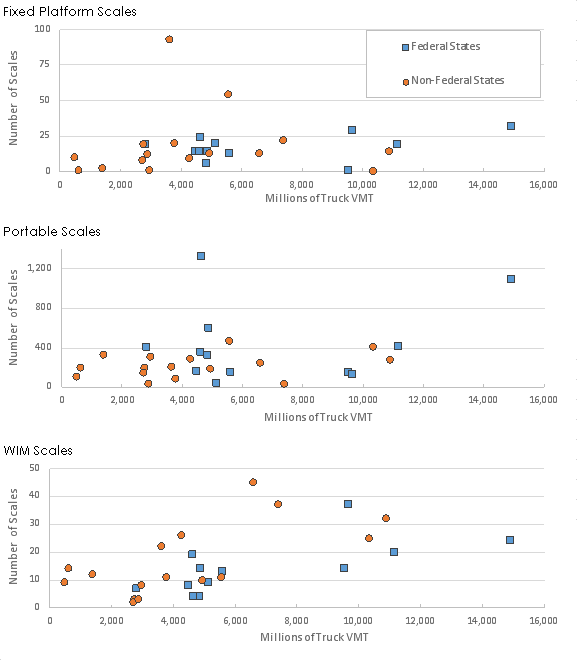

This component of the analysis in this work compares the enforcement costs and resources (i.e., weigh scales) for States that allow vehicles in excess of Federal truck weight limits (i.e., above-limit States) and States that do not allow vehicles in excess of Federal limits (i.e., at-limit States). The comparisons aim to identify state-level differences in enforcement costs and resources, and can be understood as a surrogate way of revealing potential vehicle-specific differences. The designation of the States as “at limit” and “above limit” considers three information sources:

- Relevant TSW regulations pertaining to single-semitrailer and multiple trailer trucks operating in each State (e.g., the U.S. Code of Federal Regulations, Title 23, Part 658, Appendix C) provide one indication about whether a State may be effectively at-limit or above-limit. For example, States that routinely permit triple trailer combinations on Interstate highways may be designated as above-limit States.

- Estimated 2011 vehicle miles travelled (VMT) for the scenarios’ alternative truck configurations (e.g., six-axle tractor semitrailers, triple trailer combinations) provide an indication of the extent of operation of above-limit trucks in a State by highway network type. For example, States where six-axle semitrailers commonly operate above 80,000 lb. GVW (other than those where a single-trip permit may be required) may be designated as above-limit.

- Insights from commercial motor vehicle State enforcement officials provide an experiential indication of whether a State may be designated as at limit or above limit.

As such, these comparisons do not account for State-specific variations in enforcement program delivery and permitting activities, nor do they fully consider the extent to which each truck configuration is allowed to operate within a State. Nevertheless, the comparisons provide one pragmatic approach for identifying potential cost differences associated with enforcing different types of truck configurations.

The scope of the comparative analysis includes the 29 comparison States. States included in each of these groups are listed in Table 3: States Included in Comparative Analysis. Based on these information sources for the purpose of this comparative analysis, 13 of the 29 comparison States are designated as at-limit and 16 as above-limit. As indicated earlier, the 29 comparison States were selected because they: (1) are considered to be enforcement programming leaders in the Nation, (2) have experience in enforcing vehicles subject to grandfather provisions (e.g., longer combination vehicles), or (3) have recently undertaken research and development projects related to TSW enforcement. In addition, the selection of these States addressed the need to represent general variations in trucking operations across the Nation (e.g., configurations in use, industries served) and geographic factors.

The comparative analysis focuses on costs reported for 2011 only. To help account for differences in the relative size of the TSW enforcement task in different States, all costs are normalized using 2011 estimates of truck VMT in that State. The truck VMT estimates include all single-unit trucks, single-semitrailer trucks, and multiple-trailer trucks. To reduce the impact of outlying data points, the comparison uses ranges and median values to compare costs and resources available for TSW enforcement in at-limit and above-limit States.

Truck Weight Enforcement Cost Comparisons for the Alternative Truck Configurations

The final component of the analyses in this work compares the costs associated with enforcing truck weights for the study scenarios’ alternative truck configurations relative to the control vehicles (as specified in the scenarios). As no publicly available systematic data source exists to support such analysis, information about the time required to weigh various truck configurations was gathered from seven commercial motor vehicle State enforcement officials. This information is used as the basis for estimating truck weight enforcement costs for the scenario analysis. These officials were part of a Working Group of representatives from the Commercial Vehicle Safety Alliance; this group assisted with various aspects of the Study by providing experienced-based insights. The Working Group’s membership included people in leadership positions within the CVSA community and featured several decades of experience in conducting truck size and weight enforcement program activities. All seven weighing time estimates received from the Working Group were included in the analysis. These estimates were obtained from: Arizona, Arkansas, Maryland, Michigan, North Carolina, Oklahoma, and Texas. Appendix E contains the instructions to participants and the form used to collect these data.

The time required to conduct a weighing may vary by the truck configuration being weighed and the type of weigh scale being used. State enforcement officials provided weighing times for the six alternative truck configurations and the two control vehicles being studied. The control vehicles, commonly referred to as Surface Transportation Assistance Act (STAA) vehicles, are:

- A five-axle tractor semitrailer at 80,000 lb. GVW with a 53-ft. semitrailer; and

- A five-axle tractor semitrailer-trailer at 80,000 lb. GVW[2] with one 28.5-ft. semitrailer and one 28.5-ft. trailer.

Three alternative truck configurations are compared to the five-axle tractor semitrailer control vehicle. These are:

- The five-axle tractor semitrailer at 88,000 lb. GVW with a 53-ft. semitrailer;

- The six-axle tractor semitrailer at 91,000 lb. GVW with a 53-ft. semitrailer; and

- The six-axle tractor semitrailer at 97,000 lb. GVW with a 53-ft. semitrailer.

The remaining three alternative truck configurations are compared to the five-axle tractor semitrailer-trailer (2-S1-2) control vehicle. These are:

- The five-axle tractor semitrailer-trailer at 80,000 lb. GVW one 33-ft. semitrailer and one 33-ft. trailer;

- The seven-axle tractor semitrailer-trailer-trailer at 105,500 lb. GVW with a 28.5-ft. semitrailer and two 28.5-ft. trailers; and

- The nine-axle tractor semitrailer-trailer-trailer at 129,000 lb. GVW with a 28.5-ft. semitrailer and two 28.5-ft. trailers.

For each of these truck configurations, weighing times were provided for the four main types of weigh scales: fixed static scales (including scales that weigh axle groupings and weigh bridges that weigh the whole vehicle at once), portable scales, semi-portable scales, and WIM scales (including the use of a WIM at a virtual weigh scale).

The following nine-step procedure was developed for estimating the system-wide enforcement cost impacts for each of the six scenarios. The analysis estimates the percentage change in personnel costs that could occur nationwide as a result of the traffic conditions specified by each scenario.

- Determine the proportion of VMT by truck configuration in each State for the base case defined in this Study.

- For the base case in each State, distribute the non-WIM weighings for each scale type (i.e., weighings using fixed static scales, semi-portable scales, and portable scales) according to the VMT proportions calculated in Step 1. This calculation assumes that all static weighings are conducted using scales that weigh axle groups independently, since: (1) there is no incremental weighing time associated with the alternative truck configuration when using a static weigh bridge (as is the case for single-semitrailer trucks), or (2) incremental weighing times are irrelevant if the length of the weigh bridge cannot accommodate the length of the alternative truck configuration (as may be the case for triple trailer combinations).

- Calculate base case weighing rates (i.e., the number of weighings per VMT) by State, truck configuration, and weigh scale type. These weighing rates are held constant in this analysis.

- Determine incremental weighing time factors for each truck configuration and scale type relative to the time it takes to weigh a five-axle tractor semitrailer (control vehicle) on a fixed (axle group) weigh scale. For example, according commercial motor vehicle State enforcement officials, on average, it takes about 17 minutes to weigh a six-axle tractor semitrailer using a semi-portable scale, compared to about four minutes to weigh a five-axle tractor semitrailer using a fixed (axle group) weigh scale. Therefore, the incremental weighing time factor for this comparison is 4.25 (17 divided by 4). It is assumed that the incremental time factors calculated in this way are equal to incremental personnel cost factors.

- Using the total personnel costs for each State and the incremental personnel cost factors determined in Step 4, develop an equation that can be solved to determine the average cost of weighing a five-axle tractor semitrailer (control vehicle) on a fixed (axle group) scale. This average cost is held constant in this analysis.

- In each State, multiply the new scenario VMT estimates for each vehicle configuration by the weighing rates calculated in Step 3 to determine the number of weighings by truck configuration and scale type for the scenario.

- Multiply the number of weighings for each truck configuration and scale type by the incremental personnel cost factors (for each truck configuration and scale type) determined in Step 4. The sum of these costs is the total personnel cost in each State under the scenario traffic conditions.

- Sum up the total personnel costs in each State determined in Step 7 for the scenario and compare these totals to the base case total personnel costs to determine the system-wide impacts of the scenario on personnel costs.

- Repeat Steps 6 to 8 for each scenario.

2.3 Results

This section summarizes steps and procedures for the principal TSW enforcement methods used in North America, including the application and costs of technological components and systems used to enforce truck weights. It also summarizes national-level truck weight enforcement program costs and resources (such as weigh scales) used to accomplish the enforcement task. The analysis based on this data provides information at the national level in addition to state-specific cost and resource trends (specific State names are withheld). This section also compares the enforcement costs for States that allow vehicles in excess of Federal limits and States that effectively do not allow vehicles in excess of Federal limits. Data from the subset of 29 comparison States supports this analysis. Finally, this section compares the costs of weighing the alternative truck configurations identified for the scenario analysis. By applying the nine-step procedure described in the foregoing section, the analysis also estimates the percentage change in personnel costs that could occur nationwide as a result of the traffic conditions specified by each scenario. It also estimates the enforcement cost impacts at a system-wide level for each of the six scenarios.

Principal TSW Enforcement Methods and Technologies

Technology Components

Technologies play an important role in TSW enforcement. In light of current truck travel demand levels, the resources available for TSW enforcement, and the support of ongoing research being conducted by the FHWA and the Federal Motor Carrier Safety Administration (FMCSA), technologies designed to automate enforcement activities are becoming increasingly popular with State enforcement agencies. Some technologies work well alone while others are more effective when used as a component in a broader technology system. The technologies presented in this sub-section are the components that serve as the building blocks for enforcement technology systems.

There is a subset of technologies that solely measure vehicle or axle weights for the purpose of weight enforcement. This subset (fixed static scales, semi-portable scales, and portable scales), becomes much more effective when deployed in a system-based enforcement approach. For example, when the time required to use one of these basic weighing technologies to weigh a passing truck exceeds the arrival rate of trucks required to be weighed, a more systematic approach should be considered to increase enforcement resource efficiency.

Static Scales

A static scale is a permanently fixed mechanism that is used to weigh trucks with a precision and accuracy that is suitable for issuing overweight vehicle or axle citations. The static scales require regular calibration services for certification purposes to maintain accuracy. They are typically used at weigh stations as well as private sector locations. Weigh station applications are key for weight enforcement, while private sector static scale locations are necessary for weight certification of vehicles and cargo, and are typically used for payment verification purposes by private sector businesses.

A static scale is a permanently fixed mechanism that is used to weigh trucks with a precision and accuracy that is suitable for issuing overweight vehicle or axle citations. The static scales require regular calibration services for certification purposes to maintain accuracy. They are typically used at weigh stations as well as private sector locations. Weigh station applications are key for weight enforcement, while private sector static scale locations are necessary for weight certification of vehicles and cargo, and are typically used for payment verification purposes by private sector businesses.

Static scale deployment at weigh stations provides the data necessary to identify those motor carriers that may be operating illegally (overweight without a permit). Enforcement officers sometimes use static scales to weigh vehicles that were flagged by other means (as potentially overweight) at locations in the vicinity of a weigh station. The enforcement personnel accompany the vehicle in question to the weigh station to verify the vehicle (or one or more of its axle configurations) is actually overweight and can then issue a legally enforceable citation based on the data generated by the static scale. The static scale can be used to measure the weight of the entire vehicle or it can measure axle groupings independently.

Approximate Cost:

The cost of static scales includes the necessary construction to support the in-ground equipment as well as the maintenance costs and periodic Weights and Measures certifications to ensure accuracy. Prices for static scales can range from $100,000 to $200,000 (Hanson, 2014). The size of the scale varies as does the pricing. Annual maintenance costs range from $9,000 to $18,000.

Portable Scales

Portable scales are pieces of equipment that can be transported in the enforcement officer’s vehicle and can be used on the roadside to weigh a truck. The accuracy level of portable scales is considered legally acceptable for issuing overweight citations. Portable scales are only used for individual vehicle axles; a scale is used for each side of the axle to obtain total axle weight (the measured weight of the right side of the axle is added to the measured weight of the left side of the axle to obtain a total axle weight). The enforcement officer typically places the portable scale in front of the tires of the axle to be weighed and then asks the commercial vehicle driver to roll forward and stop on top of the scale. This is done for each axle to obtain total vehicle weight as well as individual axle weights. While a truck’s total weight may not exceed the maximum allowable to operate on the roadway, it is possible that one particular axle on the truck may exceed the legal axle weight limit. A truck can be cited for exceeding the total weight or exceeding individual axle weight limits. In dangerous conditions the enforcement officer may request that, in lieu of using the portable scales, the driver follow the officer to the nearest weigh station where static scales can be used.

Portable scales are pieces of equipment that can be transported in the enforcement officer’s vehicle and can be used on the roadside to weigh a truck. The accuracy level of portable scales is considered legally acceptable for issuing overweight citations. Portable scales are only used for individual vehicle axles; a scale is used for each side of the axle to obtain total axle weight (the measured weight of the right side of the axle is added to the measured weight of the left side of the axle to obtain a total axle weight). The enforcement officer typically places the portable scale in front of the tires of the axle to be weighed and then asks the commercial vehicle driver to roll forward and stop on top of the scale. This is done for each axle to obtain total vehicle weight as well as individual axle weights. While a truck’s total weight may not exceed the maximum allowable to operate on the roadway, it is possible that one particular axle on the truck may exceed the legal axle weight limit. A truck can be cited for exceeding the total weight or exceeding individual axle weight limits. In dangerous conditions the enforcement officer may request that, in lieu of using the portable scales, the driver follow the officer to the nearest weigh station where static scales can be used.

Approximate Cost:

Portable scale prices vary and can cost between $2,000 and $4,700 per device (Hanson, 2014). Enforcement personnel typically have four portable scales per patrol vehicle and each scale must be calibrated and certified at periodic intervals to ensure their accuracy and legality. Annual maintenance costs range from $180 to $425 and include scale recertification costs.

Semi-Portable Scales

Semi-portable scales (also referred to as axle scales) are larger than portable scales, and various States use them for weight enforcement details that are temporary in nature and that can benefit from this technology, which allows for much shorter weighing times than portable scales. Semi-portable scales are suitable for issuing citations – which means they satisfy legal certification requirements. While they are cumbersome to move around (relative to transporting portable scales) and require special equipment (a trailer), they are sometimes preferred for temporary enforcement sites due to their ability to measure axle weights and total vehicle weights without the need to place individual portable scales in front of each wheel and then have the driver roll forward and stop on top of them.

Semi-portable scales allow the enforcement officer to tell the commercial vehicle driver to drive on top of the scales and stop. The officer can then record the axle weights before allowing the driver to drive forward – to be followed by the next commercial vehicle. There is no need to move the scales during this process.

Approximate Cost:

Semi-portable scale prices vary and can cost between $10,000 and $59,000 (Arizona DOT) per set. The accompanying trailer has a typical cost of approximately $10,000 (Van Heel, 2014). Annual maintenance costs for the system range from $900 to $5,300. As with portable scales, semi-portable scales must be calibrated and certified for accuracy at periodic intervals.

Weigh-in-Motion Systems

Weigh-in-motion (WIM) systems vary in appearance, cost, and accuracy. While the different technologies have their unique characteristics, all WIM systems perform the function of weighing vehicles without requiring them to stop. Some of the most popular WIM systems can be classified as:

- Piezoelectric

- Piezoquartz (Kistler)

- Bending Plate

- Single Load Cell

These systems can be placed on mainline roadways, entrance and exit ramps, city streets, and even in parking lots. Their primary value is to allow vehicles to be weighed without requiring commercial vehicle traffic to come to a complete stop. Different systems have different operating characteristics. Some WIM systems are effective at highway speeds while others are more accurate at lower speeds (0-12 MPH/0-20 KPH).

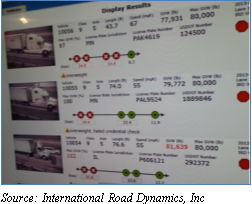

Typically, WIM systems are used as screening or sorting devices to eliminate the need to stop and weigh every truck while in transit. While WIM systems have proven to be valuable screening tools when working properly, they are not yet approved by U.S. Courts as legally acceptable for directly issuing overweight citations in the United States. When a WIM system identifies a commercial vehicle as being overweight, the enforcement officer must conduct a follow-up weighing using portable, semi-portable scales or a static scale as these are the only legal weighing systems that can be used as the basis for issuing a citation.

In addition to their use as a screening tool, WIM systems are able to store the data collected at unmanned sites for later analysis to determine commercial vehicle violation patterns and employ intelligent enforcement details. This type of data can also be used for planning purposes to determine pavement loadings experienced on roadways throughout the network. In the United States, quite often locations where WIM is installed was decided by non-truck weight enforcement purposes. Pavement engineers have used WIM for many years supporting their research programs. WIM is also installed by the states for traffic monitoring purposes that support planning activities and, hence, do not always coincide with the strategic locations required for truck weight enforcement purposes.

In terms of data availability, depending upon the system configuration, some WIM data is retrievable over the Internet and can be viewed in the home office or in manned field stations (PBS&J, 2008, pp. 4-11).

Piezoelectric Weigh-in-Motion

The basic construction of the typical piezoelectric WIM sensor consists of a copper strand surrounded by piezoelectric material, which is covered by a copper sheath. When pressure is applied to the piezoelectric material, an electrical charge is produced. The sensor is actually embedded in the pavement and the load is transferred through the pavement. The characteristics of the pavement (level approach, temperature, etc.) will therefore affect the output signal. By measuring and analyzing the charge produced, the sensor can be used to measure the weight of a passing tire or axle group.

For a complete data collection system, it is common to install two inductive loops and two piezoelectric sensors in each lane that is being monitored. Installation begins with making a relatively small saw cut in the road into which the sensor is installed. The size of the cut varies depending on the sensor being installed, but is generally 1” to 2” deep and 1” to 2” wide. The sensor is placed in the cut and secured in place by a fast-curing grout. A complete lane installation consisting of two sensors and two loops can be accomplished in less than a full day, including curing time.

For a complete data collection system, it is common to install two inductive loops and two piezoelectric sensors in each lane that is being monitored. Installation begins with making a relatively small saw cut in the road into which the sensor is installed. The size of the cut varies depending on the sensor being installed, but is generally 1” to 2” deep and 1” to 2” wide. The sensor is placed in the cut and secured in place by a fast-curing grout. A complete lane installation consisting of two sensors and two loops can be accomplished in less than a full day, including curing time.

When properly installed and calibrated, a piezoelectric WIM system should be expected to provide gross vehicle weights that are within 15 percent of the actual vehicle weight for 95 percent of the trucks measured.

Two of the advantages of this technology are that the costs are low and the technology is accepted and widely utilized. Another advantage is the minimal traffic disruption during installation.

The disadvantages, however, include inadequate precision for vehicle weight accuracy (loads can vary by as much as ±15 percent). While this technology can be used for distinguishing between loaded or empty trucks, it is not precise enough to be used for accurate screening of loaded trucks to determine which ones are overweight. In addition, this technology is highly susceptible to pavement perturbations. Equipment lifespans are shorter than some of the more expensive WIM technologies, with the piezoelectric system having a lifespan of approximately 4 years; further, pavement life affects the technology’s longevity.

Approximate Cost:

The piezoelectric system offers the lowest capital cost, the lowest cost to install and is suitable for data collection applications (low accuracy) (PBS&J, 2008, pp. 4-11).

While the initial costs for this technology are low, the necessary maintenance and calibration expenses can be considerable. The equipment cost, including electronics, for one lane is approximately $10,000 - $15,000. The total installed cost for one lane is between $25,000 and $30,000 excluding communications or traffic control costs. Tieing in additional installations within lanes at the same site cost approximately $3,500. Annual maintenance costs range from $2,250 to $2,700.

Piezoquartz (Kistler) Weigh-in-Motion System

The piezoquarts or Kistler WIM system consists of a light metal profile in the middle of which quartz disks are fitted under preload. When force is applied to the sensor surface the quartz disks yield an electric charge proportional to the applied force through the piezoelectric effect. A charge amplifier converts this electric charge into a proportional voltage, which can then be further processed as required.

The sensors can be installed in combination with other traffic detectors like induction loops, switching cables, etc. Compared to other weight enforcement technologies, Kistler WIM sensors are relatively easy to install both individually and in groups for comprehensive recording over a wide roadway.

The sensors can be installed in combination with other traffic detectors like induction loops, switching cables, etc. Compared to other weight enforcement technologies, Kistler WIM sensors are relatively easy to install both individually and in groups for comprehensive recording over a wide roadway.

Installation begins by making a relatively small saw-cut in the road into which the sensor will be installed. The size of the cut varies depending on the sensor being installed, but is generally 2.25” deep and 3” wide. The sensor is placed in the cut and secured by a fast-curing grout. A complete lane installation consisting of eight sensors and two loops can be completed in less than a day, including curing time. When properly installed and calibrated, the Kistler WIM system should be expected to provide gross vehicle weights that are within 10 percent of the actual vehicle weight for 95 percent of the trucks measured.

Installation begins by making a relatively small saw-cut in the road into which the sensor will be installed. The size of the cut varies depending on the sensor being installed, but is generally 2.25” deep and 3” wide. The sensor is placed in the cut and secured by a fast-curing grout. A complete lane installation consisting of eight sensors and two loops can be completed in less than a day, including curing time. When properly installed and calibrated, the Kistler WIM system should be expected to provide gross vehicle weights that are within 10 percent of the actual vehicle weight for 95 percent of the trucks measured.

Kistler WIM is a relatively new technology that provides suitable screening accuracy. The cost, while slightly more expensive than piezoelectric, still requires relatively little disruption of traffic for installation. Kistler WIM, as with many other WIM technologies, is not precise enough to issue a citation. This technology’s accuracy is also susceptible to pavement conditions (weather, rutting, plow damage, etc.) Additionally, an equipment lifespan of approximately 6 years is shorter than some of the more expensive WIM technologies (PBS&J, 2008, pp. 4-11).

Approximate Cost:

While the initial costs for this technology are low, the necessary maintenance and calibration expenses can be considerable. Equipment cost including electronics for one lane is approximately $25,000 to $30,000. The total installed cost for one lane is between $45,000 and $60,000 and does not include communications costs or traffic control costs. Installations in additional lanes at the same site cost between $15,000 and $18,000 (Hanson, 2014). Annual maintenance costs range from $4,100 to $5,400.

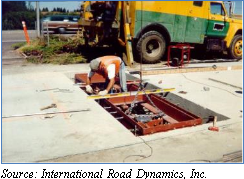

Bending Plate Weigh-in-Motion

The Bending Plate scale consists of two steel platforms, which are each 2’ by 6’, placed adjacent to each other to cover a 12’ lane. The steel plate is instrumented with strain gauges at critical points to measure the pressure in the plate as a tire or axle passes over. The measured strain is analyzed to determine the axle load. The Bending Plate scale is typically installed in a lane with two inductive loops and an axle sensor to provide vehicle length and axle spacing information.

There are two basic installation methods for a Bending Plate scale. In concrete roadways of sufficient depth, a shallow excavation is made in the surface of the road (Quick Installation). The scale frame is anchored into place using anchoring bars and epoxy. In asphalt roads or thin concrete roads, it is necessary to install a concrete foundation for support of the frame (Vault Installation). The roadway is cut and excavated to form a pit of 30” deep by 4’10” wide by 13’10” long. Then, the frame is positioned in place and cast into concrete to form a secure and durable foundation for the scale.

There are two basic installation methods for a Bending Plate scale. In concrete roadways of sufficient depth, a shallow excavation is made in the surface of the road (Quick Installation). The scale frame is anchored into place using anchoring bars and epoxy. In asphalt roads or thin concrete roads, it is necessary to install a concrete foundation for support of the frame (Vault Installation). The roadway is cut and excavated to form a pit of 30” deep by 4’10” wide by 13’10” long. Then, the frame is positioned in place and cast into concrete to form a secure and durable foundation for the scale.

Installing a complete lane of scales, loops and an axle sensor can be accomplished in less than a day using the shallow excavation method and in 3 days using the concrete vault.

When properly installed and calibrated, the Bending Plate WIM system should be expected to provide gross vehicle weights that are within 10 percent of the actual vehicle weight for 95 percent of the trucks measured.

Bending Plate WIM is a much more robust WIM technology than the piezo systems described earlier. This system is capable of withstanding weather extremes, but if incorrectly installed it can create substantially more severe consequences to the traveling public. The labor and the traffic disruption necessary to install this system are slightly greater than the piezo approaches, and the accuracy is not much better considering the additional costs. The Bending Plate system has a lifespan up to twice as long as the piezoelectric-based approaches (PBS&J, 2008, pp. 4-11).

Approximate Cost:

The costs for this technology are ‘moderate’ and the necessary maintenance and calibration expenses can be considerable. Equipment cost including electronics for one lane is approximately $25,000 - $32,500. The total installed cost for one lane is between $55,000 and $65,000 excluding communications or traffic control costs (Hanson, 2014). Installations at additional lanes at the same site cost between $15,000 and $20,000. Annual maintenance costs range from $5,000 to $5,900.

Single Load Cell Weigh-in-Motion

The Single Load Cell Scale consists of two weighing platforms with a surface size of 6’ by 3’2” placed adjacent to each other to fully cover a normal 12’ traffic lane. A single hydraulic load cell is installed at the center of each platform to measure the force applied to the scales. The load measurements are recorded and analyzed by the system electronics to determine the axle loads.

The Single Load Cell Scale consists of two weighing platforms with a surface size of 6’ by 3’2” placed adjacent to each other to fully cover a normal 12’ traffic lane. A single hydraulic load cell is installed at the center of each platform to measure the force applied to the scales. The load measurements are recorded and analyzed by the system electronics to determine the axle loads.

The installation of a single load cell scale requires the use of a concrete vault. The roadway is cut and excavated to form a pit. The frame is positioned in place and then cast into the concrete to form a secure and durable foundation for the scale. The size of the vault required measures 165” by 58” by 38”. The Single Load Cell scale is typically installed in a lane with two inductive loops and an axle sensor to provide vehicle length and axle spacing information. A complete installation of of scales, loops, and axle sensor in a single lane can be accomplished in 3 to 4 days.

The installation of a single load cell scale requires the use of a concrete vault. The roadway is cut and excavated to form a pit. The frame is positioned in place and then cast into the concrete to form a secure and durable foundation for the scale. The size of the vault required measures 165” by 58” by 38”. The Single Load Cell scale is typically installed in a lane with two inductive loops and an axle sensor to provide vehicle length and axle spacing information. A complete installation of of scales, loops, and axle sensor in a single lane can be accomplished in 3 to 4 days.

When properly installed and calibrated, the Single Load Cell WIM system should be expected to provide gross vehicle weights that are within 6 percent of the actual vehicle weight for 95 percent of the trucks measured.

Single Load Cell WIM is a more accurate WIM technology than the WIM systems described earlier. This system is capable of withstanding weather extremes, but incorrect installation consequences are substantially more severe to the traveling public. According to a FHWA study result (USDOT, FHWA, 2014a, p. 5), the Single Load Cell WIM has an accuracy level of ± 6 percent and with proper calibration and maintenance, is considered the highest among the WIM systems investigated (PBS&J, 2008, pp. 4-11).

Approximate Cost:

Approximate Cost:

The costs for this technology and the necessary maintenance and calibration expenses can be considerable; however, these are offset by the extended lifespan of the system. The equipment cost including electronics for one lane is approximately $70,000 to $90,000. The total installed cost for one lane is between $100,000 and $150,000 excluding communications or traffic control costs (Hanson, 2014). Annual maintenance costs range between $12,600 and $16,200.

It is important to note that the useful lifespan of the single load cell WIM is considerably longer than some other WIM systems, making total lifecycle costs and increased accuracy a consideration. The actual service life of a properly installed and maintained load cell site has not been estimated since load cell technology usefulness is impacted by the condition of adjacent pavement. Well-maintained surrounding pavement can yield a considerable load cell service life. Conversely, poorly maintained pavement can reduce the load cell service life due to damage caused by a non-smooth interface between the load cell and surrounding pavement.

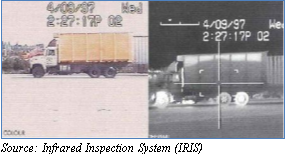

Thermal Imaging

Thermal imaging technology is a highly innovative screening tool. Many States are using this technology, which qualifies for Motor Carrier Safety Assistance Program (MCSAP) funding. What makes thermal imaging unique is that it can screen trucks, cars and even buses while they travel at normal speeds. The primary purpose for this technology is to check brakes – the single most frequent form of equipment failure responsible for placing commercial vehicles out of service. An ancillary benefit of thermal imaging is its ability to detect overloaded vehicles through the heat signature of the tires. Experienced enforcement officers have long known that overloaded tires produce large amounts of heat, which is visible to thermal imaging technology.

Thermal imaging technology is a highly innovative screening tool. Many States are using this technology, which qualifies for Motor Carrier Safety Assistance Program (MCSAP) funding. What makes thermal imaging unique is that it can screen trucks, cars and even buses while they travel at normal speeds. The primary purpose for this technology is to check brakes – the single most frequent form of equipment failure responsible for placing commercial vehicles out of service. An ancillary benefit of thermal imaging is its ability to detect overloaded vehicles through the heat signature of the tires. Experienced enforcement officers have long known that overloaded tires produce large amounts of heat, which is visible to thermal imaging technology.

Because an infrared scanner is able to measure heat, when vehicles drive along a flat grade and the brakes are not in use, the technology can detect possible brake problems. If any of the wheels measure “hot” or appear bright on the enforcement official’s display, then there is a strong possibility that this particular brake is malfunctioning. Conversely, if a truck is coming to a stop and is using the brakes, all the wheels should measure “hot” or bright on the infrared monitor. If any of the wheels are “cool” or appear dark, then those particular wheels do not have properly functioning brakes. In either case, the thermal imaging serves as a good screening tool to select vehicles for more in-depth brake inspection.

Because an infrared scanner is able to measure heat, when vehicles drive along a flat grade and the brakes are not in use, the technology can detect possible brake problems. If any of the wheels measure “hot” or appear bright on the enforcement official’s display, then there is a strong possibility that this particular brake is malfunctioning. Conversely, if a truck is coming to a stop and is using the brakes, all the wheels should measure “hot” or bright on the infrared monitor. If any of the wheels are “cool” or appear dark, then those particular wheels do not have properly functioning brakes. In either case, the thermal imaging serves as a good screening tool to select vehicles for more in-depth brake inspection.

Thermal imaging technology is deployed in multiple ways:

- Hand-held devices require an enforcement officer to merely point the device at the tires as the vehicle drives by or is stopped.

- Van-mounted devices allow the enforcement officer to sit inside the van and remotely aim the infrared device at trucks to view heat signatures.

- Devices installed at roadside (at wheel level) capture heat signatures for each truck passing the equipment.

- Devices installed beneath the pavement in the middle of a lane captures a heat signature for each wheel/brake/axle as the truck rolls over the device.

Enforcement personnel can use this thermal imaging data to select potentially unsafe (or overweight) trucks to intercept, inspect, and, if warranted, remove the unsafe or overweight vehicles from the roadway.

Approximate Cost:

The costs for thermal imaging technologies can vary.

- Hand-held units can cost between $6,000 and $10,000, depending upon the unit.

- Roving vans fully equipped with thermal imaging systems can cost approximately $300,000.

- Roadside-mounted thermal imaging technology can cost approximately $150,000.

- Subsurface thermal imaging technology can cost approximately $250,000 and has the added cost of roadway construction (Taylor, 2014).

Maintenance costs for these technologies vary depending upon the type of system used. Handheld maintenance costs can range from $540 to $900, and mobile van systems maintenance costs are approximately $27,000 per year. Roadside fixed system maintenance costs are $13,500 and subsurface mounted system maintenance costs can reach $22,500 per year.

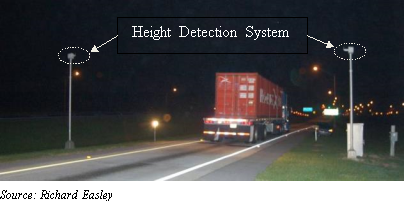

Height Detection System

A height detection system will consist of a laser detector or optical sensor which points across the roadway at a certain height and includes a method of communication to alert the driver, or enforcement personnel, when a vehicle exceeding an pre-determined height drives past. When a vehicle breaks the laser beam, it can trigger a series of safety measures including warning the driver, providing the driver with an alternate and safe diversion, or alerting motor carrier enforcement that a triggering event has occurred. While there are no height restrictions in Federal law or regulation, most States impose enforceable State height limits ranging from 13.6 feet to 14.6 feet (USDOT, FHWA, 2014b).

Height detection systems can be valuable in areas with low overpasses or where tunnels are present. In addition, these systems can prove valuable in areas where accidents related to high winds regularly occur, such as on bridges. With respect to size and weight enforcement, when this technology is deployed near a weigh station, any triggered events can alert enforcement personnel to check for the proper permits or issue citations if the proper permits have not been purchased (i.e., the oversized vehicle is not operating legally).

Approximate Cost:

The cost to furnish and install the two poles, light source, optical sensor and associated equipment is approximately $30,000 (Hanson, 2014). Yearly maintenance costs are approximately $2,700.

Three Dimensional Measuring Systems

Three dimensioning (3D) technology is one of the tools used to measure a vehicle’s width, height, and length. By scanning the vehicle as it passes the reader, an image is processed and analyzed. This data is then converted into the vehicle’s dimensions.

Three dimensioning (3D) technology is one of the tools used to measure a vehicle’s width, height, and length. By scanning the vehicle as it passes the reader, an image is processed and analyzed. This data is then converted into the vehicle’s dimensions.

There are several approaches to obtaining 3D imaging, which can include side readers as well as overhead readers, as image accuracy is sensitive to laser reader installation angle. While this technology cannot determine a vehicle’s weight for enforcement purposes, it can identify those commercial vehicles that exceed legal width restrictions. As noted previously, while there are no Federal height restrictions, most States impose enforceable State height limits ranging from 13.6 feet to 14.6 feet (USDOT, FHWA, 2014b).

There are several approaches to obtaining 3D imaging, which can include side readers as well as overhead readers, as image accuracy is sensitive to laser reader installation angle. While this technology cannot determine a vehicle’s weight for enforcement purposes, it can identify those commercial vehicles that exceed legal width restrictions. As noted previously, while there are no Federal height restrictions, most States impose enforceable State height limits ranging from 13.6 feet to 14.6 feet (USDOT, FHWA, 2014b).

To date this technology is not approved for citation issuance purposes, but is an efficient screening and data collection tool.

Approximate Cost:

Costs for 3D systems vary; the furnish and install price is estimated at $235,000 (Hanson, 2014). Annual maintenance costs for these systems are estimated at $21,200.

Closed Circuit Television (CCTV) Systems

Closed Circuit Television (CCTV) Systems

Closed Circuit Television (CCTV) cameras and more advanced video image detection systems are relatively inexpensive technologies that can monitor truck activity on weigh station bypass routes. Video image detection systems use machine vision technology to compile and analyze traffic data collected with CCTV systems. Video image detection can automatically monitor freeway conditions, capture speeds, and count and classify vehicles.

There are many benefits to CCTV deployment including the ability to “see” commercial vehicle traffic on remote roadways, on major thoroughfares, or any location that can be viewed from the public right-of-way. These traffic images can be viewed in real-time or the images can be stored and viewed at a later date. An added benefit is that the CCTV data can be viewed from anywhere with Internet access and by any enforcement personnel with the appropriate access permissions.

Using CCTV Cameras to monitor bypass routes can provide true counts of commercial vehicles, and limited truck body type information (e.g., logging trucks, car carriers, tanker trucks, etc.) can be collected. Today there are many cameras in use that capture images of vehicles as they are detected (by various types of sensor technologies) when certain sensor criteria are met. For example, sensors can activate CCTV cameras when a specific classification of vehicle is detected, a weight threshold is exceeded, speeds are exceeded, etc. This is helpful for enforcement when a vehicle is determined to be overloaded, over-height, or over-length. The CCTV image can be used to identify the vehicle by an enforcement officer in the immediate vicinity or for analysis at a later date.

Approximate Cost:

The cost for this technology ranges from $10,000 to $50,000 for a color CCTV camera, and annual maintenance costs range from $200 to $1,000 (Hanson, 2014). This assumes an existing communications link and does not include the software systems and algorithms for automated surveillance.

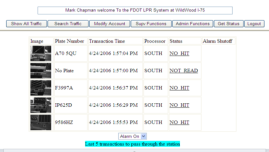

License Plate Recognition

License plate reader (LPR) technology is the application of a camera and sophisticated software (optical character recognition (OCR)) which takes the image of a license plate and converts that image to alpha-numeric characters. This license plate information can be stored in a database or the software can perform a “look up” for a matching license plate in a database that may contain stolen tags, Amber Alert information associated with a tag or other information.

License plate reader (LPR) technology is the application of a camera and sophisticated software (optical character recognition (OCR)) which takes the image of a license plate and converts that image to alpha-numeric characters. This license plate information can be stored in a database or the software can perform a “look up” for a matching license plate in a database that may contain stolen tags, Amber Alert information associated with a tag or other information.

Applications can include such simple “look ups” as identifying truck license plates that regularly use a bypass route.

LPR technology can be used in daylight as well as nighttime using various lighting techniques including infrared lighting, Xenon lighting, light-emitting diode (LED) lighting, etc.

LPR technology can be used in daylight as well as nighttime using various lighting techniques including infrared lighting, Xenon lighting, light-emitting diode (LED) lighting, etc.

LPR technology can be used on virtually any truck with a license plate—in other words, all of them, since every commercial vehicle has to mount a license plate in order to operate legally on US roadways. In addition, the technology does not require any additional equipment to be installed on the truck – such as a transponder. The camera captures a license plate image for each truck bypassing the sensors. Using OCR software, the system attaches data to the image that indicates whether or not the plate was successfully read and the time, date and location of the read; and it also indicates whether or not the license plate number is in either a State or Federal crime database.

While LPR can be used to capture vehicle identification and conduct license plate “look ups,” it cannot capture the weight of the vehicle. LPR technology is generally used in conjunction with WIM technology. While LPR is used in various applications around the world including toll enforcement, parking operations, and speed enforcement, it is still rather limited in its accuracy for trucking enforcement operations. Due to the large number of license plate designs, finishes (reflective), colors, and various states of disrepair (paint chipped off, dirty, bent, swinging from a hinge, odd location on the front of the truck, etc.) the technology has a limited “read” capability. However, vendors for such equipment continue to improve LPR technology performance.

While LPR can be used to capture vehicle identification and conduct license plate “look ups,” it cannot capture the weight of the vehicle. LPR technology is generally used in conjunction with WIM technology. While LPR is used in various applications around the world including toll enforcement, parking operations, and speed enforcement, it is still rather limited in its accuracy for trucking enforcement operations. Due to the large number of license plate designs, finishes (reflective), colors, and various states of disrepair (paint chipped off, dirty, bent, swinging from a hinge, odd location on the front of the truck, etc.) the technology has a limited “read” capability. However, vendors for such equipment continue to improve LPR technology performance.

Approximate Cost:

Costs for LPR systems will vary; installed costs range from $90,000 to $150,000 including OCR (Hanson, 2014). This includes the necessary software required to analyze the images and produce the digital numbers and text suitable for recordkeeping and running database queries. Annual maintenance costs can range from $8,100 to $13,500.

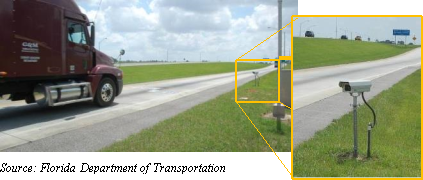

Optical Character Recognition (USDOT Readers)

Similar to LPR technology, optical character recognition technology in its simplest form is the application of a side-fired digital camera and sophisticated OCR software that takes the image of a USDOT number and converts that image to alpha-numeric characters. This USDOT information can be stored in a database or the software can “look up” the matching DOT number in a database that may contain DOT numbers of motor carriers with poor safety records, motor carriers that are delinquent on payment of International Registration Plan (IRP) or International Fuel Tax Agreement (IFTA) fees, or other violation information. This technology can be used in daylight as well as nighttime. The system employs various lighting techniques to illuminate the USDOT number, including infrared lighting, Xenon lighting, LED lighting, etc.

OCR systems can be used to identify motor carriers that consistently bypass weigh stations or that consistently operate when weigh stations are closed. Using this type of motor carrier-specific operations data—in conjunction with WIM scale data—enforcement officials can identify violators and respond with appropriate legal actions.

OCR, while becoming more popular, is still not close to 100 percent accuracy, and errors are not uncommon. Experience has shown that OCR performance has not matched that of LPR because of the technical challenges of interpreting the non-standard presentation of the USDOT numbers (varying size, color, location and background color).

Approximate Cost:

Costs for USDOT reader systems will vary; installed costs range from $90,000 to $150,000 including OCR. This includes the necessary software required to analyze the images and produce the digital numbers and text suitable for recordkeeping and running database queries. Annual maintenance costs can range from $8,100 to $13,500.

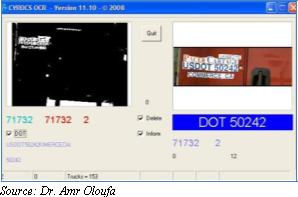

Container Character Recognition

Similar to LPR technology, container character recognition (CCR) technology is the application of a camera and sophisticated OCR software that takes the image of a container number and converts that image to text and numbers. This container ID information can be stored in a database or the software can search for a matching container number in a database that may contain stolen container information, Homeland Security information, or other information.

This technology can be used in daylight as well as nighttime. The system employs various lighting techniques, including infrared lighting, Xenon lighting, LED lighting, etc. Especially relevant for overweight violation detection and citation is the ability to identify the container separate from the chassis. Each chassis has a license plate, but if the container is transferred to a different chassis, the overloaded container could not be traced without the container’s unique ID. Because chassis are an interchangeable component of all intermodal freight movements, a technology that specifically identifies the container, regardless of the chassis underneath, becomes valuable for locating overweight containers.

CCR systems can be used in the vicinity of marine and rail intermodal operations. This technology allows enforcement officials to track containers from the time they are unloaded from a ship or train until the container crosses jurisdictional boundaries. This information could be helpful in achieving the U.S. Department of Homeland Security’s desire for cargo visibility, which could prove useful to State and local agencies as well as the Federal government.

CCR systems can be used in the vicinity of marine and rail intermodal operations. This technology allows enforcement officials to track containers from the time they are unloaded from a ship or train until the container crosses jurisdictional boundaries. This information could be helpful in achieving the U.S. Department of Homeland Security’s desire for cargo visibility, which could prove useful to State and local agencies as well as the Federal government.

CCR camera placement is not the same as LPR placement in that CCR cameras must capture the container number on the rear or side of the container whereas LPR must find and read the license plate on the front of the truck.

Approximate Cost:

Costs for these systems vary; the installed price is estimated between $90,000 and $150,000 including OCR. This includes the necessary software required to analyze the images and produce the digital numbers and text suitable for recordkeeping and running database queries. Annual maintenance costs can range from $8,100 to $13,500.

Transponder Technology (DSRC)

Transponder Technology is synonymous with Radio Frequency Identification (RFID) Tags or dedicated short range communications (DSRC) and uses radio frequency to communicate between a truck-mounted tag and a roadside tag reader. This two way communication link is primarily utilized on the Interstate system to identify a specific truck (or company) or run a quick database check to determine if the truck is in compliance (paid taxes, etc.). It can also alert the driver to pull into the weigh station or port-of-entry to be inspected. Transponder readers need to be compatible with transponders used for any particular DSRC system.

One of the advantages of using RFID technology is that it can identify the motor carrier as the truck travels down the highway without decreasing speed. As long as the jurisdiction has a database link to the truck, a great deal of information can be obtained – especially when married with a WIM system. When combined with a WIM system, commercial vehicle enforcement officers can stop the truck and issue an overweight citation (using a portable or static scale) or the data can be analyzed at a later date and warnings can be issued to the offending motor carriers. The disadvantage of DSRC in this application is that it can only identify the carrier and the truck; without combining DSRC with WIM, there is no weight information. The other challenge with relying solely on using DSRC for vehicle identification is that only a very small percentage of trucks actually carry these DSRC tags and participate in the electronic screening programs. To compound this, the various DSRC programs are not interoperable, so a transponder that can be identified in one State may not be recognized in another State.

Approximate Cost:

The costs for DSRC screening technology is approximately $25-$75 per tag. Depending upon the program the carrier enrolls with, the carrier may or may not have to purchase the tag. Additional costs are necessary to purchase transponder readers, deploy the requisite communications technology, and install/support the software programming necessary to operate the system.

CVIEW and Automated Permitting Systems

The Commercial Vehicle Information Exchange Window (CVIEW) is a system that allows enforcement personnel to collect the pertinent data for a commercial vehicle from several disparate databases. Rather than stopping a commercial vehicle and then checking multiple databases for information pertaining to operating authority, possession of appropriate permits, etc., the CVIEW software system searches all relevant databases and compiles the information on one screen so the enforcement officer can run all necessary checks and the commercial vehicle driver is not delayed any longer than necessary.

The Commercial Vehicle Information Exchange Window (CVIEW) is a system that allows enforcement personnel to collect the pertinent data for a commercial vehicle from several disparate databases. Rather than stopping a commercial vehicle and then checking multiple databases for information pertaining to operating authority, possession of appropriate permits, etc., the CVIEW software system searches all relevant databases and compiles the information on one screen so the enforcement officer can run all necessary checks and the commercial vehicle driver is not delayed any longer than necessary.

Automated Permitting Systems allow the motor carrier to apply for, pay for, and receive oversize and overweight permits online in an automated fashion. This method is much quicker for the motor carrier and allows permit office personnel to concentrate on more complex duties while the simple permit requests are handled through an automated process. An automated permitting benefits both the motor carrier and permit office staff in terms of efficiency, but it also benefits enforcement personnel at the roadside because the overweight or oversized vehicles’ permits can quickly be verified through a CVIEW link to the automated permit database.

Approximate Cost:

CVIEW technology costs vary from jurisdiction to jurisdiction and depend upon the legacy system interfaces as well as development of any new databases. A CVIEW (or CVIEW equivalent) can cost as little as $30,000 or as much as $600,000. Annual maintenance costs for these systems can range between $2,700 and $54,000 depending upon the complexity of the system.

Automated Permitting Systems can vary greatly in price as well. An important factor is the required system functionality. The complexity of the programming greatly increases the cost. Also, some jurisdictions have the ability to develop their own systems while other jurisdictions choose to hire an outside vendor to create their program. Still other systems are created and operated by a third party vendor that charges service fees to the jurisdiction, thereby reducing the initial programming and hardware procurement cost.

Technology Systems

Technologies serve a specific purpose and most are designed to fulfill that purpose efficiently and effectively. It is often advantageous to deploy combinations of technologies to satisfy multiple and varying enforcement objectives. Such strategic enforcement systems utilize the technologies discussed previously.

The following technology system descriptions will vary from agency to agency depending upon capital budgets, locations, traffic conditions, weather, availability of space, type of freight movements, and availability of weight enforcement personnel.

Non-Fixed Weigh Sites

Non-fixed weigh sites are those locations that are used for inspections or weighing vehicles. Unlike weigh stations which are typically staffed and fully configured for commercial vehicle enforcement activities, non-fixed weigh sites are locations that are not staffed, may or may not have any commercial vehicle enforcement equipment, and are only utilized on a temporary basis. For purposes of this report, only the following two types of non-fixed weigh sites will be discussed.

- Plug and Play Sites

- Roving Sites

Both Plug and Play Sites, and the Roving Sites have a variety of configurations. They are used for conducting short term enforcement activities with a relatively low budget. However, once the commercial vehicle industry members that are operating illegally learn where a non-fixed weigh site is in operation, they may either reroute their trips or park and wait for the non-fixed weigh site to shut down – typically, just a matter of hours.

Both Plug and Play Sites, and the Roving Sites have a variety of configurations. They are used for conducting short term enforcement activities with a relatively low budget. However, once the commercial vehicle industry members that are operating illegally learn where a non-fixed weigh site is in operation, they may either reroute their trips or park and wait for the non-fixed weigh site to shut down – typically, just a matter of hours.

Plug and Play Sites

Plug and Play sites are those locations where some level of infrastructure exists but it is not used for enforcement if enforcement officers are not onsite. There are many configurations for this type of site, and any number of combinations of infrastructure may accommodate the types of technology used in such sites, including:

- Weigh-in-Motion Technology

- License Plate Reader Technology

- Closed Circuit Television Cameras

- Optical Character Recognition (for USDOT number reads)

- Container Character Recognition (for container number reads)

- Variable Message Signs (to alert trucks to stop)

- Height Detection Technology

- A small building structure to house or plug in computer equipment to operate any of the onsite technology

Plug and Play sites can also have any combination of equipment brought along with the enforcement personnel to complement the existing equipment already onsite. This can include:

- Portable Scales

- Thermal Imaging Technology

Approximate Cost:

The cost for a Plug and Play site is dependent upon the technologies used at the particular location. Some Plug and Play sites may be configured differently depending upon geographic limitations or the targeted violator group (e.g., logging trucks, containers, etc.).

Roving Sites

Roving Sites are those locations chosen for commercial vehicle enforcement activities that contain no enforcement facilities or technologies but simply have enough space to perform weighings and inspections safely. These sites are typically chosen based on a calculated enforcement strategy.

A roving site could be located at:

- A rest area parking lot,

- A paved or gravel pullout along the roadway, or

- Any site deemed safe for weighing and inspection that is utilized by commercial vehicle traffic.

Roving sites require the commercial vehicle enforcement personnel to bring all of the equipment they would need to conduct their weighings and inspections. The combination of equipment used at a Roving Site depends upon the objectives of the inspections. A roving site could be a random location to pull over one truck based on a suspected safety violation, or it could be a pre-determined location where all trucks are stopped along that particular route. Inspections could be for any combination of the following objectives:

- Checking weight of the vehicles,

- Conducting an equipment check (brakes, cargo securement, tires, lights, etc.),

- Driver credentials or operating credentials (IRP, IFTA, permits, etc.), or

- Other reasons.

Equipment utilized at a Roving Site could include:

- Portable Scales

- Semi-Portable Scales (larger scales that require a hauling trailer and assembly is required)

- Portable Transponder Reader

- Thermal Imaging Device

- Brake Testing Device

Some enforcement agencies use vans that are adequately equipped to set up inspection or weigh sites at any location deemed appropriate.

Approximate Cost:

The cost for a Roving Site is dependent upon what technologies would be used at the particular location. Some Roving Sites may require different equipment depending upon the geographic limitations, objective of the mission, etc.

Fixed Weigh Sites

Fixed weigh sites are those locations that are permanent and have staff assigned to operate them. Commercial vehicle enforcement personnel operate the facility on a regularly scheduled basis. Some sites operate 24 hours per day while others may shut down every evening. Fixed weigh sites typically require a large amount of land and can be very expensive to build. Space requirements vary by jurisdiction. Some jurisdictions require office space for multiple agencies (e.g., weight enforcement and law enforcement). In some areas of the country all weigh station activities are conducted under a single agency while in others States share duties between various agencies. Fixed sites are usually located on high-volume roadways (Interstate System, National Highway System routes, etc.) and several activities are conducted onsite. These activities can include:

- Weighing the trucks (issuing citations if warranted),

- Conducting safety inspections,

- Issuing permits,

- Checking for proper operating credentials,

- Examining Bills of Lading to ensure taxes are paid and cargo is not prohibited,

- Providing restroom facilities for drivers, and

- Providing a parking area for trucks that are placed out of service or for drivers that need rest (some include WiFi).

The fixed weigh sites can use many technologies to perform commercial vehicle enforcement duties more efficiently. The technologies that can be found at a fixed weigh site can include:

The fixed weigh sites can use many technologies to perform commercial vehicle enforcement duties more efficiently. The technologies that can be found at a fixed weigh site can include:

- Static Scales

- Weigh-in-Motion

- License Plate Readers

- Optical Character Readers (USDOT Readers)

- Container Character Reader

- CCTV

- Thermal Imaging

- Height Detectors

- Three Dimensional Imaging

- Brake Testing Technologies

- Vehicle and Cargo Inspection Systems (VACIS)

- Transponder Readers

Fixed weigh sites are costly and most jurisdictions have found that while the need for more sites is increasing, the costs for additional sites makes building the number of facilities needed cost prohibitive. Because there are relatively few fixed weigh sites and many route alternatives, some motor carriers that may be overweight or unable to pass a safety inspection find bypass routes to avoid being stopped at a fixed weigh site. Also, some carriers find that they lose valuable time when they have to undergo inspections or other time consuming requirements at fixed weigh sites and attempt to find bypass routes. The technologies operating at fixed weigh sites help to minimize commercial vehicle delays by automating time consuming activities, but these technological advancements have minimal value if overweight and unsafe carriers choose to find bypass routes and never enter a fixed weigh site.

Fixed weigh sites are costly and most jurisdictions have found that while the need for more sites is increasing, the costs for additional sites makes building the number of facilities needed cost prohibitive. Because there are relatively few fixed weigh sites and many route alternatives, some motor carriers that may be overweight or unable to pass a safety inspection find bypass routes to avoid being stopped at a fixed weigh site. Also, some carriers find that they lose valuable time when they have to undergo inspections or other time consuming requirements at fixed weigh sites and attempt to find bypass routes. The technologies operating at fixed weigh sites help to minimize commercial vehicle delays by automating time consuming activities, but these technological advancements have minimal value if overweight and unsafe carriers choose to find bypass routes and never enter a fixed weigh site.

Approximate Cost:

Fixed weigh sites can cost upwards of $15 to $35 million dollars depending upon the weigh site configuration, the various environmental studies, construction costs, land acquisition costs, etc. The VACIS technology by itself can cost more than $1.5 million dollars. The VACIS utilizes gamma ray technology to produce images revealing cargo content without the need to open trailers or containers. Annual maintenance costs for technologies associated with a fixed weigh site can average $80,000, depending upon the configuration (Taylor, 2014).

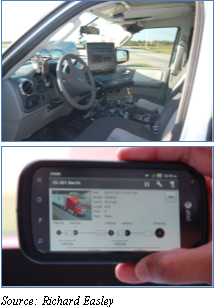

Unmanned Fixed Weigh Sites

The unmanned fixed weigh site is similar in concept to the fixed weigh site, but it is operated remotely. This concept is one that allows enforcement personnel to use technology to weigh vehicles, check vehicle dimensions, determine if a vehicle is current on taxes, registrations, permits, etc. This concept also allows for thermal imaging brake checks as well as visual inspections. While unmanned fixed weigh sites cannot match the full services that a fixed weigh site can with onsite enforcement personnel, it utilizes technology to the fullest extent to perform some basic weigh site functions.

One of the models of an unmanned fixed weigh site is to use channelized lane flows that direct trucks to a window-height kiosk with a camera. The driver is then asked questions, if warranted, and required to places any needed paperwork on the scanner located in the kiosk. This information is relayed to the weigh station operator that may be at the manned fixed weigh station on the opposite side of the highway, or the operator may be in a central location where multiple unmanned fixed weigh sites across the jurisdiction are managed.

The configurations for an unmanned fixed weigh site can vary greatly, but typically will have CCTV visibility, static scales, WIM technology, and perhaps restroom facilities. Most will have ample parking space for vehicles to wait until enforcement personnel arrive to provide assistance or issue citations if warranted. This space can also be used when vehicles are placed out of service for oversize or overweight violations, incomplete paperwork, or visual safety inspection irregularities.

Approximate Cost:

Costs for unmanned weigh sites vary depending upon the size and cost of real estate and needed improvements (pavement, utilities, construction, etc.), the technologies deployed, and the facilities included (restrooms, small office, etc.). Costs range from $10 – $20 million. Annual maintenance costs for technologies associated with an unmanned fixed weigh site can average $80,000, depending upon the configuration (Taylor, 2014).

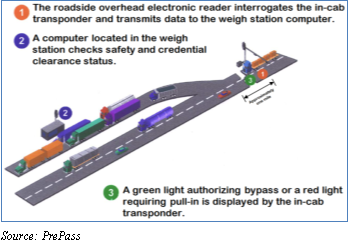

Electronic Screening Systems

Electronic screening systems originated in the early 1990’s to demonstrate the concept that trucks could travel from Texas to California and north to British Columbia without being required to stop at weigh stations. This electronic screening demonstration would enable those carriers that are operating safely and legally to bypass crowded weigh stations so long as they continue to operate safely and legally. The concept for electronic screening systems is based on an electronic check of a truck or motor carrier’s information, which is located in a database and accessed when the truck comes into the vicinity of a weigh station. If, based on the information in the jurisdiction’s database, the truck is deemed to have a satisfactory safety record and is operating with all legally required credentials, the driver is electronically notified that he/she may bypass the weigh station.

Electronic screening programs exist in most States today, but not all systems are interoperable. There are variations in communication methods, variations in technology system requirements, variations in database ownership (State-owned or third-party-provider owned database for checking motor carrier records to determine eligibility for weigh station bypass), and variations in cost structures for electronic screening systems (State funded, motor carrier funded, or combination).

Electronic screening systems use a combination of technologies including:

- Transponders and Transponder Readers

- Weigh-in-Motion

- Cellular Communications (smart phones, e-tablets, laptops, etc.)