Enhancing Transportation: Connecting TSMO and DesignPrintable version [PDF 834 KB]

U.S. Department of Transportation FHWA-HOP-18-088 December 2018 WHAT IS TSMO? Transportation systems management and operations (TSMO) is the use of strategies, technologies, mobility services, and programs to optimize the safety, mobility, and reliability of the existing and planned transportation system. A significant cause of congestion and unreliable travel is non-recurring events, such as crashes, and transportation network disruptions, such as bad weather, and special events. TSMO enables agencies to target the underlying operational causes of congestion and unreliable travel through innovative solutions that typically cost less and are quicker to implement than adding capacity. TSMO expands the range of mobility choices available to system users, including shared mobility and nonmotorized options. This Fact Sheet is part of a series that explains how TSMO relates to other State and local transportation agency functions and offices. Other Fact Sheets focus on how TSMO relates to: performance management, maintenance, design, safety, environment, planning, human resources, and construction. The typical highway project life cycle starts with planning and then moves to design, construction, and maintenance. Historically, the day-to-day operation of the facility after project completion has received less attention. Design personnel, transportation planners, and operations staff can work together to enhance the linkage between design and operations. For example, some States are now working to more fully incorporate operations into their project development processes and design manuals. Considering facility operation during the design process and incorporating TSMO strategies into facility design can improve system performance for little cost. TSMO strategies help agencies improve the safety, reliability, and cost-effectiveness of their infrastructure projects. Designing with TSMO in mind results in several benefits, including:

Designing for TSMO can reduce the frequency and impacts of temporary transportation system disruptions that cause congestion and unreliable travel times. For example:1

TSMO can Play Multiple Roles in the Infrastructure Design Process

Considering TSMO in the Project Design PhasesSample design treatments that support TSMO:

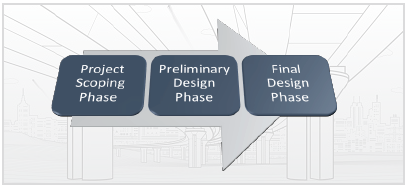

TSMO strategies can be implemented at each point of the design process to improve project outcomes and long-term operational efficiency. Agencies benefit from developing formal policies and procedures for including TSMO strategies and making operational considerations throughout the design process, as outlined in Figure 1.  Figure 1. Project Design Phases

Performance Based Practical Design modifies the traditional highway design process by taking a "design up" approach, where transportation decision makers exercise engineering judgment to build up the improvements from existing conditions to meet both project and system objectives. By taking into account TSMO strategies during the performance-based practical design process, designers can expand the variety of design options available to them and perhaps postpone or reduce the need for conventional capacity improvements. For example, designing shoulders to support the TSMO strategy of part-time shoulder use by public buses reduces delay during peak congestion periods and provides additional capacity as needed, but the shoulder reverts to its original use during non-peak travel periods. How Has This Worked In Practice?

The SHRP2 Reliability by Design tool can help with analyzing how design strategies can improve travel time reliability. This is a spreadsheet-based analysis tool that helps agencies estimate the effectiveness and comparative economic benefits of design treatments at specific locations. To download the tool, go to: http://www.trb.org/Main/Blurbs/169768.aspx.

For More Information

Joseph Gregory, Federal Highway Administration 1 Strategic Highway Research Program (SHRP 2) Report S2-L07-RR-2: Design Guide for Addressing Nonrecurrent Congestion, 2014. Available at: http://www.trb.org/Main/Blurbs/169768.aspx. [ Return to note 1. ] 2 Transportation Systems Management and Operations and Performance Based Practical Design Case Study 4: Demonstrating Performance-Based Practical Design through Regional Performance-Based Planning, FHWA, 2016. Available at https://ops.fhwa.dot.gov/publications/fhwahop16038/index.htm. [ Return to note 2. ] 3 Designing for Transportation Management and Operations: A Primer, FHWA, 2013. Available at https://ops.fhwa.dot.gov/publications/fhwahop13013/fhwahop13013.pdf [ Return to note 3. ] 4 Ibid. [ Return to note 4. ] 5 Ibid. [ Return to note 5. ] 6 TSM&O Evaluation, Colorado Department of Transportation, 2018. Available at https://www.codot.gov/programs/operations/tsmo-evaluation.[ Return to note 6. ] |

|

United States Department of Transportation - Federal Highway Administration |

||