Anti-Icing Saves Time and Money

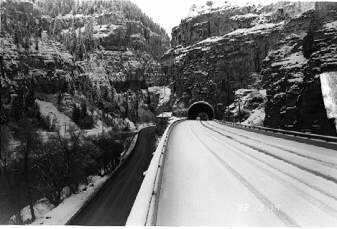

By applying anti-icing chemicals to roads before snow and frost accumulate and bond to the pavement, Colorado is cutting costs, reducing maintenance requirements, and making travel safer.

The Challenge

A large portion of the highway department budget in Colorado is consumed by winter maintenance operations directed at snow and ice removal. The Colorado Department of Transportation (DOT) sought a better strategy than the traditional method of waiting for snow to fall and then dispatching plows and salt or sand trucks to clear the roads. This method can be inefficient in several ways:

- It is more difficult to clear snow and ice once they have bonded to the pavement than it is to prevent that bond from forming initially.

- There is often a delay between when the storm hits and when maintenance crews are geared up and ready to go.

- Road crews often do not have enough information about a storm's intensity, causing them to treat the pavement with too much or too little sand and chemicals.

Developing a Strategy

Colorado DOT, as well as the cities of Aspen, Boulder, Denver, and Lakewood, decided to try new anti-icing techniques that were evaluated under the Strategic Highway Research Program (SHRP). These new techniques rely on accurate, site-specific weather forecasts that pinpoint when and where a storm will hit and how much precipitation will occur.

Putting the Strategy to the Test

Using liquid magnesium chloride, "crews are sent out in advance of the storm to treat roads and bridges to prevent snow and ice from sticking to the pavement," says Alex Ariniello, director of the Colorado Transportation Information Center at Colorado State University.

What They Learned

The anti-icing techniques have proved successful. For example, since Boulder began using a liquid solution comprising 29 percent magnesium chloride and 71 percent water in 1993, sand use has decreased by 55 percent. When all costs are considered, using the liquid chemical costs $2,500 per lane mile, as compared to $5,200 for deicing and sanding operations.

Denver is also discovering the benefits of magnesium chloride. In 1995, the city reduced its 40,000 tons of sand and salt mixture by 2,000 tons and replaced it with 130,000 gallons of the anti-icing chemical.

The Benefits

- Clearer roads meant safer driving conditions.

- Maintenance costs were reduced.

- Fewer chemical applications resulted in less damage to cars, pavements, and roadside landscaping.