V. SPECIAL CHALLENGES

A. RAILROAD CROSSINGS

Because railroad crossings and other grade fluctuations present high levels of risk for oversize loads with low ground clearance, pilot/escort vehicle operators (P/EVO) must be familiar with the oversize load and its limitations in order to be able to warn highway users and load drivers of problematic crossings.

The combination of high-profile crossings and low-clearance vehicles presents great challenges in moving oversize loads. Railroad tracks are built up to create effective drainage. Frequently, abrupt changes in the level of the road surface as the road crosses the tracks increases the risk of low clearance vehicles becoming stuck at the crossing.

All railroad crossing and grade changes should (or as required by the States) be included in the route survey, along with emergency contact numbers for each crossing. This information should be reviewed daily; that is, before starting travel for the day, the load movement team should be reminded of the procedures to be followed if the load should become lodged at a crossing. However, it is important to remember that the decision about whether to traverse a crossing remains with the load driver.

The hazards include the fact that trains cannot stop quickly. It can take more than a mile for a train to stop once emergency brakes are applied. In addition, freight trains average a mile in length and travel at 50 to 60 mph and more.3

In addition, it is critical to remember that many trains have hundreds of passengers on them, and stopping distances for passenger trains are comparable to those for freight trains. A 150-car freight train at 50 mph needs 8,000 feet (1 and 1/2 miles) to stop; an 8-car passenger train at 79 mph needs about 6,000 feet (1 and 1/8 miles) to stop.

Stopping distances for trains are substantially longer primarily because of the weight of the train, but stopping a train includes processes similar to those involved in stopping other vehicles: stopping distance is the sum of perception time, reaction time, brake lag, and braking distance. The contact area between a train's steel wheels and the steel rails is about the size of a dime, producing limited amounts of the friction that is needed to stop a train.4

Vehicles with a deep-well or low-boy chassis are used to gain vertical clearance when transporting large loads through tunnels and under bridges. These trailers, however, may not have sufficient ground clearance to traverse high-profile rail crossings or other grade changes. Other vehicles, particularly long loads, may exceed the space available between highway-rail crossings and nearby highway-highway intersections or traffic control devices. This creates a situation in which a load may become stuck on the tracks during a red light. These situations must be avoided. A load vehicle should never start across a track or series of tracks unless the load can traverse all the tracks without stopping and without shifting.

IF LOAD BECOMES LODGED AT A RAILROAD CROSSING

Hanging up on a railroad crossing is a dangerous predicament, and is becoming too common as more very low trailers are manufactured. Lowboy trailers, car carriers, moving vans, and possum belly livestock trailers are particularly susceptible, as are single-axle tractors pulling a long trailer with landing gear which is set to accommodate a tandem-axle tractor.5

If hung at a railroad crossing, first, get out of the vehicle and off the tracks. Locate the crossing information (if it isn't on the route survey or permit), and call the railroad to let them know the vehicle is lodged on the track.

- Get out of the vehicle and off the tracks immediately. Do not go back onto the tracks for any reason.

- Move away from the tracks. Move TOWARD an oncoming train, and AWAY from the tracks. When a vehicle is struck by a train, debris moves in the same direction the train is moving.

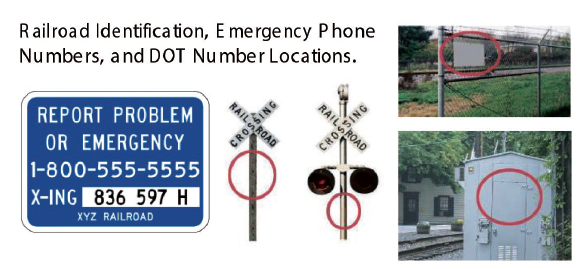

- Locate the emergency phone number and department of transportation crossing identification number (this should be included in the route survey) located near the intersection of road and rail. (See illustration below.)

- Call for help. Call the railroad's emergency phone number to let them know the vehicle is lodged on the track.

- Call the local police or 911. This is especially important if you cannot locate the railroad emergency phone number at the site. Describe the situation and the exact location. Ask local authorities to notify the railroad and assist on site as soon as possible.

- If a train approaches, move as far as possible from the track(s).6

Figure 1: Illustration. Information for reporting trouble on a track.

Figure 1: Illustration. Information for reporting trouble on a track.

Detailed plans about the response of each individual team member if the load becomes lodged at the crossing should be set out during the pre-trip meeting. Every member of the team must know how to find the emergency contact information for railroad companies and what his or her exact responsibility is if this hazard becomes an emergency. P/EVOs should assist local law enforcement in controlling traffic until the issues are resolved and the load is safely off the tracks.

RAILROAD CROSSING SAFETY REMINDERS

Based on safety information from Operation Lifesaver, the Federal Motor Carrier Safety Administration (FMCSA), American Association of Motor Vehicle Administrators, and others, P/EVOs must keep the following things in mind when the designated route includes railroad crossings:

- Never race a train to a crossing.7 Slow down when approaching a crossing in case a train is present. Be prepared to stop at the first railroad warning sign, at least 15 feet from the crossing.

- Look up and down the tracks. It is difficult to judge the distance and approach speed of a train. If in doubt, be safe, stop, and wait.

- Keep your rear in the clear. Trains are wider than the tracks, typically 6 feet beyond the rail.8 Be sure to leave some "living" room.9

- If it won't fit, don't commit. FMCSA states, "Do not enter a crossing unless you can drive completely though without stopping." Further, because trains are wider than the track, there must be enough room on the other side for the back of the truck and any overhanging cargo to avoid stopping until the load is at least 6 FEET past the last rail at the crossing.10

- Don't expect to hear a train both because of the noise inside the vehicle and the sounds of the engine. Don't rely on the signals. Don't rely on the train whistle. Noise inside the vehicle may be too loud to hear the warning.

- Remember that a full stop is required for certain vehicles and cargo, especially hazardous materials and tankers. When stopping, be sure to watch traffic from behind, and turn on emergency flashers when stopping to reduce the likelihood of being struck from behind.

- Be especially alert at passive crossings—those that do not have gates or flashing red signal lights.

- Remember that multiple tracks require multiple checks; a train on one track may hide a train on another track.

- Be cautious about obstructions that may block the view of an approaching train— vegetation, buildings, standing railcars, etc.

- Be completely sure that the load is able to cross all tracks without changing gears, braking, or stopping.11 FMCSA recommends the load driver keep moving once starting over the tracks, even if lights start flashing and the gates come down. Make sure any traffic lights or stop signs are far enough past the tracks to allow the load to completely cross and be an adequate distance from the tracks before stopping.

- Expect a train on any track at any time. Approach each crossing with the expectation that a train is coming.12

- Be alert to weather and how it affects conditions at the crossings, such as impaired sight distance and substantially increased stopping distances not only for highway traffic but also for the train.

- Recognize that in certain areas and at certain times, trains may have several hundred passengers on them.

As a quick reference, print the FMCSA's railroad safety visor card and put one in every escort vehicle and the load vehicle(s). Be sure to mention the rules and hazards of any crossings anticipated for that day at daily pre-trip meetings, and review the contingency plans. Verify the contact information for notifying railroads of emergency situations.

B. TALL LOADS AND OVERHEAD OBSTRUCTIONS

When loads are tall, the lead P/EVO must use a height pole. States vary, but if a height pole is required it is typically specified on the permit. Height pole operation is designed to prevent the load from hitting bridges, power and utility lines, signs, traffic lights, and other primarily overhead obstructions. In many States, a load is considered over-height if it is taller than 13' 6", although Western States frequently have higher thresholds.

The height pole should (or as required by the States) be made of a non-conductive, non- destructive flexible material and should (or as required by the States) be securely mounted on the escort vehicle in order to avoid creating a hazard to surrounding motorists and vehicles, transportation infrastructure, the escort vehicles, or the load vehicle. The height pole is mounted on the front of the lead escort vehicle and must be calibrated as described below.

The P/EVO operating the height pole must have an unobstructed view of the pole and must be far enough ahead of the load to be able to communicate to the load driver in enough time to get the load stopped before striking any overhead obstruction.

CALIBRATION OF THE HEIGHT POLE

States vary in what they require when installing the height pole; the established best practice is that all height poles should be, at a minimum, set from 3 to 6 inches above the tallest part of the load. Measure the load and set the height pole, with the assistance of the load driver. Confirm the height with the load driver.

C. STEERABLE TRAILERS/TILLERMAN OPERATIONS

A tillerman or steerman is an individual who steers any axle of an articulated trailer. The FMCSA has revised current regulatory guidance13 on the role of the "driver" versus that of the "tillerman," a person exercising control over the movement of a steerable rear axle on a commercial motor vehicle. The agency had previously determined that although a tillerman does not control the vehicle's speed or braking, the rear-axle steering he/she performs is essential to prevent the trailer from offtracking into other lanes or vehicles or off the highway entirely, and because this function is critical to the safe operation of vehicles with steerable rear axles, the tillerman was considered a driver and thus subject to commercial motor vehicle (CMV) regulations. However, the agency more recently concluded the person operating the steerable rear axle should be classified as a "tillerman." FMCSA indicated it considers the tillerman's physical location in, on, or around a CMV to be the most relevant factor in determining whether the person is a driver, and that anyone controlling a steerable rear axle from outside the CMV would be doing so under the direction of the person in the cab, and therefore should not be considered a driver.14 (See 49 CFR Parts 383 and 390 for clarification.)

As with most other P/EVO regulations, it is necessary to check with the State agency that oversees oversize load permits and P/EVO operations to find out what the rules are regarding steering articulated trailers. It is not recommended and unlawful in many States, for a single individual to perform two driving tasks simultaneously; that is, functioning as both the P/EVO and the tillerman at the same time. This is true regardless of how the trailer is steered. In many States, a tillerman/ steerman must have a Class A commercial drivers license.

3 Federal Highway Administration, Pilot Car Escort Best Practices Guidelines, FHWA-HOP-04-026 (Washington, DC: FHWA, 2004), p. 25-26. [ Return to note 3. ]

4 Ibid. [ Return to note 4. ]

5 American Association of Motor Vehicle Administrators, AAMVA Commercial Driver's License Manual, (n.d.), p. 2-28 to 2-30. Available at: http://www.aamva.org/CDL-Manual/. [ Return to note 5. ]

6 U.S. Department of Transportation, Accidents That Shouldn't Happen: A Report of the Grade Crossing Safety Task Force to Secretary Federico Pena, p. 28. Available at: https://safety.fhwa.dot.gov/xings/docs/taskforcereport.pdf. [ Return to note 6. ]

7 American Association of Motor Vehicle Administrators, AAMVA Commercial Driver's License Manual, (n.d.), p. 2-29. Available at:

http://www.aamva.org/CDL-Manual/. [ Return to note 7. ]

8 Ibid. [ Return to note 8. ]

9 Operation Lifesaver, "Highway-Rail Grade Crossing Training for Professional Truck Drivers," (n.d.). Available at: http://oli.org/images/page/OLTDGuide15stayalive(1).pdf. [ Return to note 9. ]

10 Federal Motor Carrier Safety Administration, 7 Steps for Safety: Highway-Rail Grade Crossings, FMCSA–ESO–06–0014 (Washington, DC: FMCSA, 2015 revision). Available at: https://www.fmcsa.dot.gov/sites/fmcsa.dot.gov/files/docs/Highway-Rail%20Safety_English.pdf.. [ Return to note 10. ]

11 American Association of Motor Vehicle Administrators, AAMVA Commercial Driver's License Manual, p. 2-30. [ Return to note 11. ]

12 Ibid., p. 2-28. [ Return to note 12. ]

13 "Regulatory Guidance on the Designation of Steerable Rear Axle Operators (Tillermen) as Drivers of Commercial Motor Vehicles," A Rule by the Federal Motor Carrier Safety Administration issued on June 06, 2011, Federal Register. Available at: https://www.federalregister.gov/articles/2011/06/06/2011-13902/regulatory-guidance-on-the-designation-of-steerable-rear-axle-operators-tillermen-as-drivers-of . [ Return to note 13. ]

14 "Groups ask for clarification on 'tillerman' definition," Commercial Carrier Journal, June 6, 2011. Available at: http://www.ccjdigital.com/groups-ask-for-clarification-on-%E2%80%98tillerman%E2%80%99-definition/. [ Return to note 14. ]