Slide 1:

KANSAS CITY TERMINAL RAILWAY FLYOVER PROJECT

A Public / Private Cooperative Success

Slide 2:

Success and Inter-Railroad Cooperation...

Slide 3:

Public/Private Partnership that Worked.

Slide 4:

CURRENT PROBLEM

Slide 5:

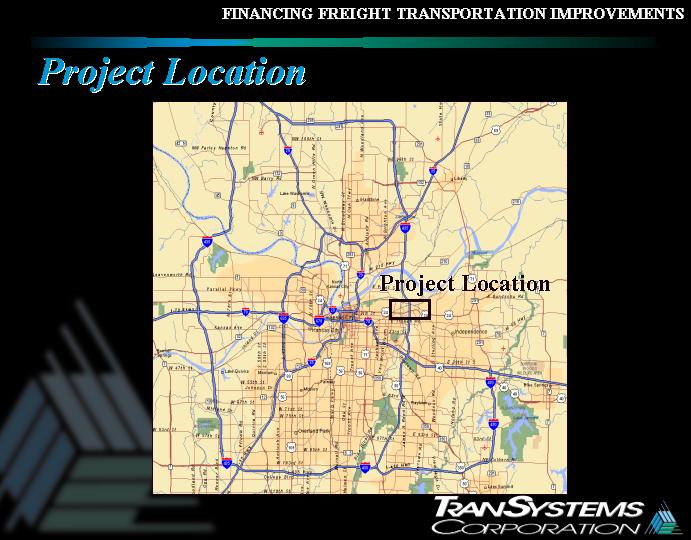

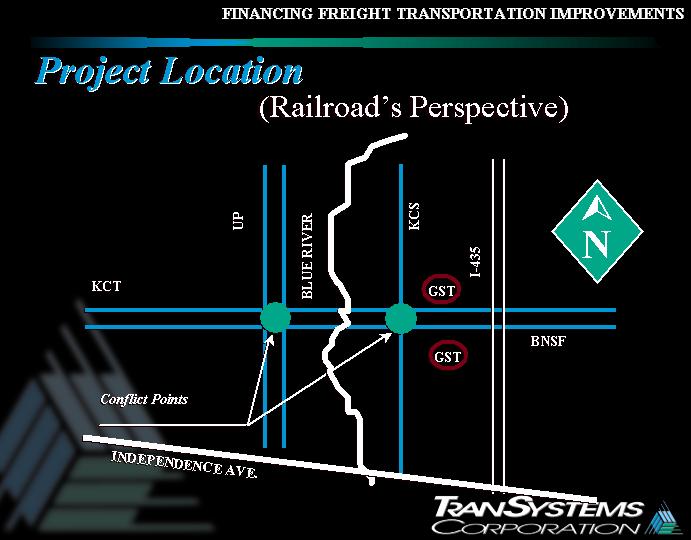

Project Location

Slide 6:

Project Location (Railroad’s Perspective)

Slide 7:

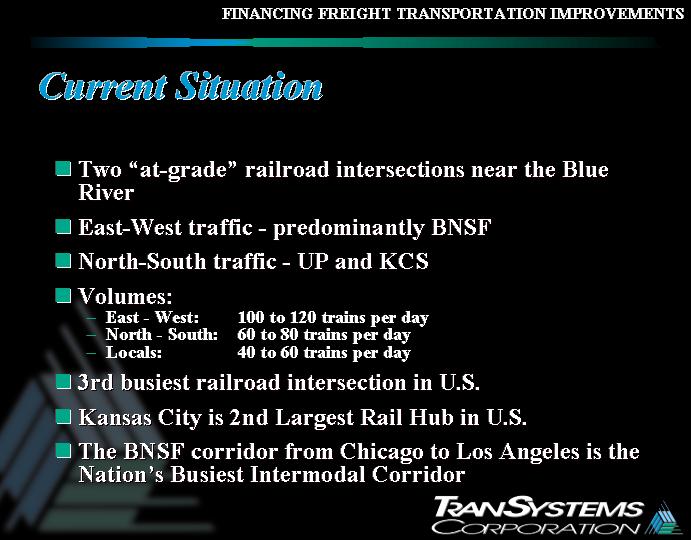

Current Situation

Two “at-grade” railroad intersections near the Blue River

East-West traffic - predominantly BNSF

North-South traffic - UP and KCS

Volumes:

– East - West: 100 to 120 trains per day

– North - South: 60 to 80 trains per day

– Locals: 40 to 60 trains per day

3rd busiest railroad intersection in U.S.

Kansas City is 2nd Largest Rail Hub in U.S.

The BNSF corridor from Chicago to Los Angeles is the Nation’s Busiest

Intermodal Corridor

Slide 8:

The picture of KANSAS CITY TERMINALRAILWAY

Slide 9:

Why Now?

Originally deemed unfeasible to grade separate

Traffic volumes have increased to a point where operating efficiencies have

been lost on the Terminal Railroad

Recent mergers, and subsequent trackage rights agreements, have enabled more

traffic to use the intersection

Inter-railroad cooperation is on the rise

Slide 10:

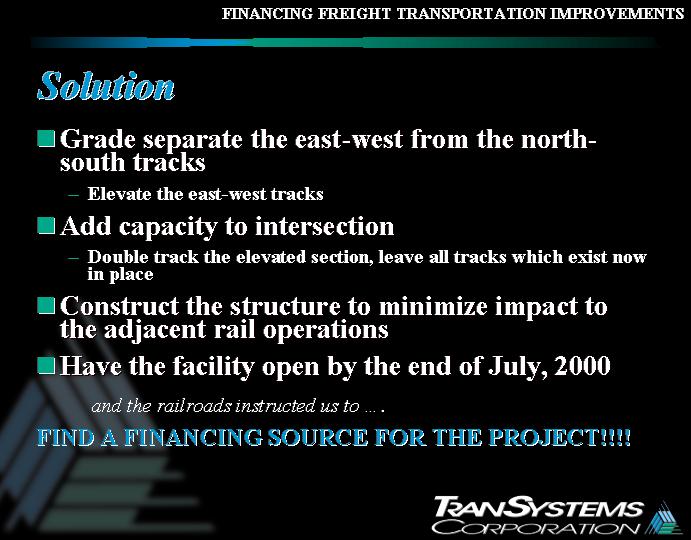

Solution

Grade separate the east-west from the north-south tracks

– Elevate the east-west tracks

Add capacity to intersection

– Double track the elevated section, leave all tracks which exist now

in place

Construct the structure to minimize impact to the adjacent rail operations

Have the facility open by the end of July, 2000

and the railroads instructed us to ….

FIND A FINANCING SOURCE FOR THE PROJECT!!!!

Slide 11:

Even Though It Was a Rail Project...

How could the Public Sector Be Brought In?

Slide 12:

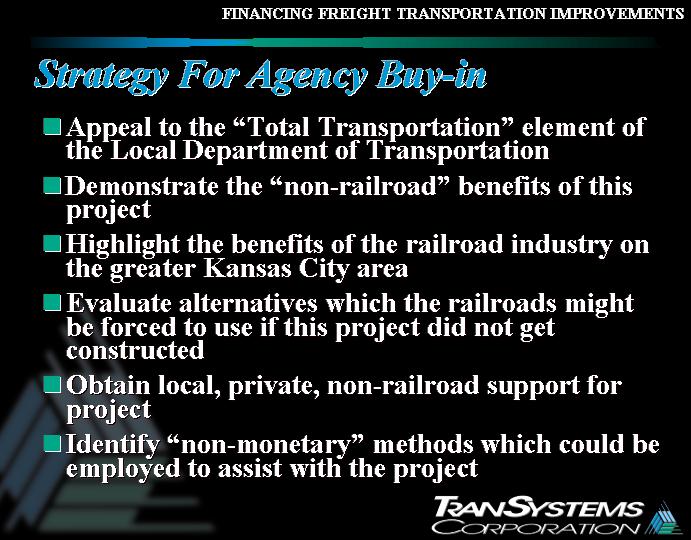

Strategy For Agency Buy-in

Appeal to the “Total Transportation” element of the Local Department

of Transportation

Demonstrate the “non-railroad” benefits of this project

Highlight the benefits of the railroad industry on the greater Kansas City area

Evaluate alternatives which the railroads might be forced to use if this project

did not get constructed

Obtain local, private, non-railroad support for project

Identify “non-monetary” methods which could be employed to assist

with the project

Slide 13:

Agencies/People Contacted

City of Kansas City, Missouri

Mid-America Regional Council (MPO)

Missouri Department of Transportation

Economic Development Corporation of Kansas City, Missouri

Missouri Department of Economic Development

Missouri Development Finance Board

Greater KC Chamber of Commerce

Slide 14:

Search for Financial Assistance

Railroads did not mind paying for the project if a source for capital could

be found up front

“OFF BALANCE SHEET FINANCING”

Results of Agency Coordination

– All parties very positive towards project

– Very few programs (economic development) are geared to assist a transportation

related project such as this

– No dedicated monies are available for such projects

Slide 15:

Project Champions

Missouri Department of Transportation

City of Kansas City, Missouri

– Both provided excellent leadership and guidance in finding potential

financing sources

– Both were willing to forget about conventional methods of financing

a project and look towards innovative methods

– State utilized their lobbyist in DC and their relationship with FHWA

Staff to move project along

Slide 16:

Problems Encountered

Kansas City is an Air Attainment City, therefore no CMAQ funds are available

State of Missouri prohibits the use of fuel tax dollars on any other form of

transportation other than highways

Hard to quantify the direct economic benefit of the project due to the unwillingness

of the railroads to divulge future plans

Slide 17:

Help from Washington, DC?

Assistant Administrator Garvey was very helpful. Ms. Garvey set us up with the

FHWA Innovative Finance Team where we had several meetings.

FHWA was supportive of project, but needed to identify the public benefit that

the project would produce.

– The fact that this is the #1 intermodal rail corridor in the U.S. was

not enough – the Team wanted to quantify “hard” benefits to

the public – primarily the highway users of the area.

Slide 18:

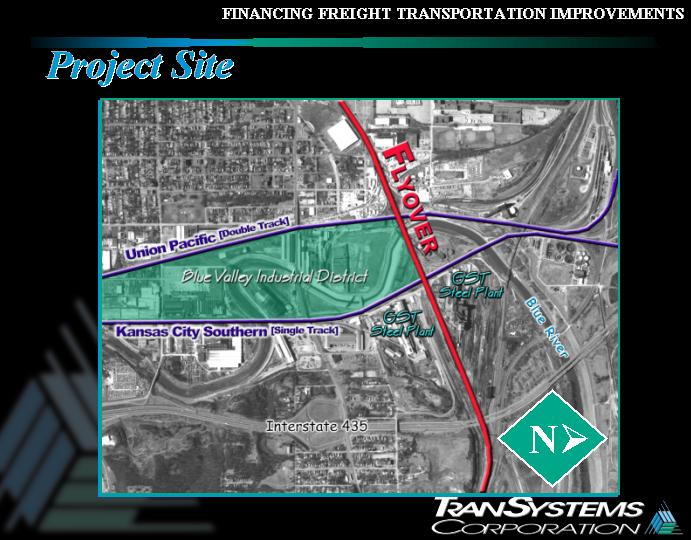

Project Site

Slide 19:

Project Location (Public’s Perspective)

Slide 20:

Delayed Train Impact

(from the Public’s Perspective)

100 North/South Trains Per Day

60% are Northbound

Average Delay Time = 20 minutes; at 10 mph average, it takes nearly 6 minutes

for a train to go by a crossing.

Assuming 4,500 vehicle movements per day through the area, Delay = 530 hours

per day.

Using a $14/hour average cost, $1.85 million/yr.

Significantly Increases Air Emissions

Slide 21:

Financial Help from Washington, DC!!!

On May 27, 1997 we received a letter from FHWA approving the project for a Section

129 loan, with a corresponding line of credit provided by future STP Federal-Aid

Highway Funds destined for Missouri.

– The Letter allowed up to 25% of the cost of the project to be funded

this way. 25% was determined to be the public benefit.

– Railroads were pleased as this insured government long-term interest

rates on at least 25% of the project.

Slide 22:

Help Disappears!!!!

A letter dated November 3, 1997 was received by MoDOT stating that the Section

129 Loan was being rescinded by FHWA for the Flyover Project.

Why????

The trucking lobby objected to the use of FHWA funds for this purpose.

Slide 23:

Transportation Corporation

State of Missouri Statute

– Sections 238.300 - 360

Transportation Corporation (T-Corp) language allows the following:

– For a quasi-governmental entity to be created which will be represented

by the Missouri Highway Commission and the project owner

– The T-Corp will be allowed to issue State tax exempt bonds to finance

a project with up to 20 years as a repayment schedule

– The T-Corp carries with it an ad valorem property tax abatement

Originally created to accelerate highway projects in the state

Slide 24:

T-CORP Bond Issues

Need to create “off balance sheet” financing:

– Quasi-governmental entity did the trick

Desire for low (T-Bond) interest rates:

– Underlying credit of the Railroads was OK individually, but increased

significantly when the BNSF and the UP took the project over and agreed to sign

joint/several agreements – to nearly T-Bond rates.

Goldman Sachs, along with a local, Kansas City brokerage handled the transaction.

$75 million was issued, however $172 million was subscribed.

Slide 25:

T-CORP Bond Issues (cont.)

Bonds are retired entirely by railroad activity through this area of Kansas

City – no direct public money went into the project.

State of Missouri did require hard asset pledges from the railroads to cover

their exposure.

T-Corp had to control the land upon which the project was constructed. When

bonds are retired, the land reverts back to railroad control.

Slide 26:

THE CITY’S ROLE

Slide 27:

City Responsibilities

Although railroad property taxes are assessed at the State level however any

abatements are subject to approval by the local jurisdiction

The development of the T-Corp requires approval by all surrounding jurisdictions,

which in this case, is Kansas City, Missouri, Independence, Sugar Creek and

Jackson County

Slide 28:

Property Tax Abatement

Single largest financial element of the entire project

The addition of this structure would increase that liability to $1.9 million

per year

The $1.4 million/year abatement makes up for nearly 20% of the yearly bond amortization

Slide 29:

Additional City Assistance

Utility coordination

– 14 different utilities in this old industrial portion of the City

Street Reconstruction

– A portion of Wilson Avenue will need to be reconstructed and temporarily

closed to facilitate construction of the project

Land Swap

– Construction was actually required on City property, requiring a permanent

land transfer from City to Railroad.

Slide 30:

City Received...

Slide 31:

Solution...

Slide 32:

Benefits of Flyover

Reduces time which nearby industries get “trapped” by trains

– May stimulate economic activity in the Blue Valley Industrial District

– Eliminates problems to area businesses: e.g.. fire protection, emergency

medical service and security issues.

Improves AMTRACK service:

– Reduces delays

– Improves speeds

Environmental Impact:

– Trains idling for up to 2 hours contribute to the areas air pollution.

Slide 33:

BENEFITS (cont.)

This serves as a catalyst project for the area’s railroad industry - it

eliminates the congestion point allowing for a significant expansion of rail

assets in the area:

– BNSF’s Argentine Yard - $100 million

– BNSF’s Murray Yard - $50 million

– KCS’s Richards-Gebaur - $50 million

– KCS’s Knoche Yard - $40 million

– Norfolk Southern’s Auto Mixing Facility - $70 million

– UP’s Line Capacity - $60 million

– Flyover - $75 million

– Argentine Flyover and High Line Rehab. - $115 million

Slide 34:

THE PROJECT

Slide 35:

Project Specifics

Overall project length = 15,300’

Length of main bridge portion = 6,740’

Additional bridges of 890’ and 150’

Double-track structure

Structure will essentially fit on existing KCT right-of-way

Project has been extended east 3/4 mile

Overall Project Cost = $75,000,000

Slide 36:

The picture of project site.

Slide 37:

Project Facts

94,549’ (17.9 miles) of H-Piles

6,567’ of drilled shafts (mostly 54” & 84” dia.)

26,592 cu. yds. of concrete (without drilled shaft concrete)

Over 320 prestressed concrete girders (24,205’ or 4.6 miles)

18,221,225 lbs. (9,110 tons) of structural steel

Slide 38:

A Successful Public/Private Partnership