Advanced Transportation & Congestion Management Technologies Deployment (ACTMTD) Proposal: Next Generation Management of the I80 Corridor for Bridge Performance, Damage, and Load Capacity

PART A – Project Description

The Iowa Department of Transportation (DOT) is seeking $ 4,423,280 in Advanced Transportation & Congestion Management Technology Deployment (ATCMTD) grant funding from FHWA for a technology deployment project to utilize intelligent transportation system (ITS) vehicle-to- infrastructure (V2I) communications tools to expedite and improve the agency's safety and weight screening of commercial motor vehicles (CMV). The federal grant funding will be matched at least 50:50 by non-federal funds.

This ATCMTD-funded project will continue Iowa DOT's forward-leaning use of state of the art technology for smarter, more proactive, data-driven decision-making in planning, programming and operations. The technology deployments to be accomplished in this two-part project will enable the department's Office of Motor Vehicle Enforcement (MVE) to be more effective and efficient in using its motor carrier enforcement resources to deter and detect violators, with minimal disruption to safe, legal weight CMV operators, in pursuit of the twin goals of protecting both public safety and the State's increasingly vulnerable highway infrastructure assets.

Specifically, this ATCMTD grant will help fund deployment of two advanced traffic management system (ATMS) technology elements:

- Virtual weigh stations (VWS) in two corridors along Interstate 35 in the Des Moines Metro area and Interstate 80 from Iowa City to Davenport

- Enhanced electronic credential screening (e-screening), using automated license plate readers (ALPR) and USDOT number readers, at eight roadside fixed-scale safety and weight enforcement sites in major truck corridors across Iowa

This project will leverage MVE's existing high-level statewide law enforcement citation and vehicle safety inspection reporting data base and ITS infrastructure capabilities, as well as its aggressive CMV safety and weight enforcement efforts. It will add new ITS infrastructure and capabilities. The net result will be enhanced and more efficient detection and deterrence of CMV safety and weight violations, which will improve the safety of all road users and will better protect highway and bridge infrastructure assets, as well as minimize time delays and inconvenience to safe, legal weight CMV operators. Successful development and real-world implementation of practical concepts of operations for VWS and enhanced e-screening through this project will serve as a best-practice model for other states to emulate.

Application Entity

This ATCMTD grant application is being made by the Iowa Department of Transportation. The acquisition and deployment of the technologies described herein will be accomplished thru a multi-disciplinary partnership of Iowa DOT operating divisions, led by the Motor Vehicle Division. The Office of Motor Vehicle Enforcement, a major work unit within the Motor Vehicle Division, will manage the project, including management of project funding.

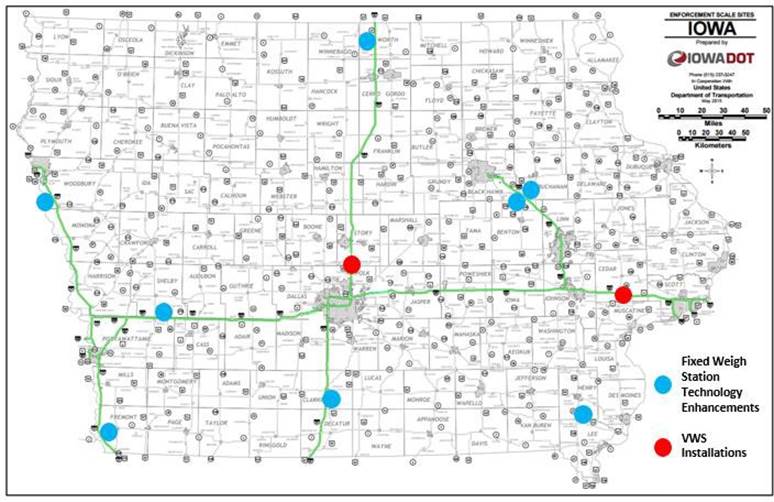

Geographic Areas Served by Deployment

The VWS installations that will be enabled with this ATCMTD funding will serve two of Iowa's most important truck-borne freight highway corridors: I-35 north of Des Moines in central Iowa and I-80 in eastern Iowa, both of which are in the National Highway Freight Network. Upgrading the credential screening capabilities of eight existing roadside scale facilities will serve other important truck-borne freight highway corridors on Iowa's Primary Highway system.

Figure 1 - Proposed VWS Sites and Enhanced e-Screening Installations

Issues and Challenges

Every state is responsible for enforcing federal and state safety and weight laws and regulations applicable to CMVs operating on its highway system. Over the past several decades, the nearly century-old traditional methods of physically stopping and inspecting a small sample of CMVs at fixed roadside scale facilities to determine compliance with these laws and regulations have been enhanced with the roll out of a variety of technological innovations. These technologies have included:

- Lightweight, portable, electronic-interfaced, axle weight (wheel load) scales for mobile enforcement operations

- Weigh-in-motion (WIM) and camera-assisted virtual (or vehicle) weigh-in-motion (VWIM) systems, for both mainline applications and roadside scale entrance ramps

- Electronic credential screening (e-screening), using automated license plate recognition technology, USDOT number readers, or vehicle-specific identification devices, supplemented with electronic interfaces with state and federal motor carrier safety/vehicle registration data bases for real-time queries

- Infrared tire, wheel bearings and brake scanners, and performance-based brake testers

- Over-dimension (height, length and width) and radiation detection systems

- Scale entrance ramp queue length detection systems

Where they have been deployed, these technological innovations have helped increase the efficiency and effectiveness of state motor carrier enforcement efforts. However, funding in many states – including Iowa – has not kept pace with the growing demand for deployment of these technologies. The result has been improved deterrence/detection of unsafe and/or overweight trucks in some highway corridors, but not in others. This has left gaps in CMV enforcement coverage and capabilities, inhibiting states from maximizing their ability to ensure highway safety and to protect their highway and bridge infrastructure assets. It has also prevented states from more fully using V2I technology to reduce travel time delays imposed on safe/legal weight trucks at roadside scale facilities.

Iowa DOT's Office of MVE has primary responsibility for statewide enforcement of compliance with federal and state CMV regulations. The core business function of MVE's sworn enforcement officers is two-fold: (1) to operate the agency's 12 fixed-site safety and weight enforcement scales located on main truck corridors throughout Iowa and (2) to supplement those scale operations with mobile patrol operations on other Iowa highways. During these scale and patrol operations, MVE officers not only conduct weight inspections, but also carry out CMV driver and vehicle condition/credential inspections, following Federal Motor Carrier Safety Administration (FMCSA) Motor Carrier Safety Assistance Program (MCSAP) guidelines. Unfortunately, due to legislatively-mandated budget constraints, the number of MVE officers has been reduced over the past decade.

Furthermore, Iowa's highway infrastructure is aging faster than it can be repaired or replaced. For example, in 2016, nearly 5,000 of the 24,184 bridges in Iowa – a staggering 20.5 percent of all bridges – were deemed structurally deficient. This meant that for the second year in a row, Iowa ranked Number One among the 50 states in the number of structurally deficient bridges.

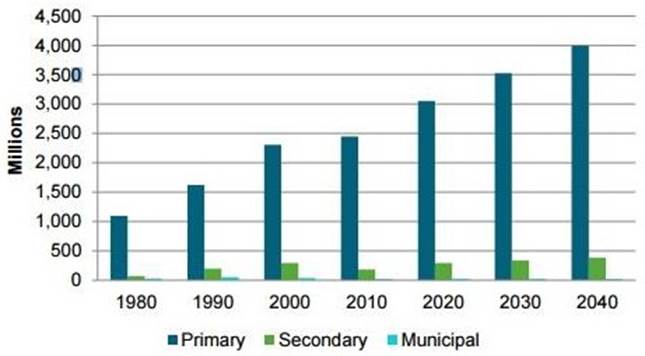

Compounding Iowa DOT's infrastructure asset protection challenge is the amount of freight tonnage carried by trucks on Iowa's highways continues to increase. Authoritative forecasts suggest truck-borne freight tonnage will increase 92% by 2040 (compared to 2011) – see Table 1. This scenario is not unique to Iowa. Like its motor vehicle enforcement counterparts across the nation, Iowa MVE has great incentive to continue making smart, technology-assisted, data-driven decisions on how best to utilize its available personnel and facilities to maintain an effective deterrence/detection effort.

|

2011 | 2020 | 2030 | 2040 | 2011 - 2040 % Change |

|---|---|---|---|---|---|

Truck |

864.3 |

1,121.2 |

1,367.9 |

1,661.2 |

92.2% |

Rail |

84.2 |

97.6 |

106.5 |

121.8 |

44.7% |

Multiple Modes & Mail |

14.9 |

16.5 |

18.0 |

20.4 |

37.4% |

Pipeline |

7.3 |

8.2 |

7.9 |

7.9 |

7.2% |

Water |

7.3 |

8.5 |

9.2 |

10.0 |

36.8% |

Other and Unknown |

2.4 |

3.2 |

4.0 |

4.9 |

100.8% |

Air (includes Truck-Air) |

0.0 |

0.0 |

0.1 |

0.1 |

232.5% |

TOTAL |

980.5 |

1,255.2 |

1,513.6 |

1,826.3 |

86.3% |

Source: FHWA, Freight Analysis Framework

Since 1980, large truck traffic on Iowa's primary roads has increased more than two-fold, with the highest truck volumes being experienced on I-80 in eastern Iowa – see Figure 2. During this same period, vehicle miles of travel (VMT) by large trucks on Iowa's secondary roads has also increased substantially, while truck traffic on municipal roads has remained relatively stable. Large truck VMT is expected to continue to increase through the next two decades, which will impact Iowa's highway system in the form of increased congestion and deteriorating pavement and bridge conditions.

Figure 2 - Iowa Large Truck VMT by Jurisdiction (1980 - 2040)

To partially compensate for its inability to increase personnel to keep pace with increased CMV operations in Iowa's main highway freight corridors, MVE has increasingly deployed PrePass® technology since 2000. Nationwide, PrePass has evolved into a widely used, subscription-based, advanced automated vehicle identification (AVI) transponder technology that enables qualified motor carriers to electronically demonstrate compliance with federal and state safety, weight and credential requirements while traveling at highway speed. To date, six of MVE's 12 fixed-site weigh scales have been equipped with the PrePass V2I screening/sorting technology. Since MVE's initial deployment of PrePass in 2000, over 3.7 million successful – and legally permitted – scale bypasses by CMVs have been achieved, resulting in an estimated reduction of over 3,200 metric tons of emissions, and saving the motor carrier industry about 300,000 hours of driver time, nearly 1.5 million gallons of fuel, and nearly $27 million in operating costs.

At Iowa DOT scales with PrePass deployment, MVE officers are able to focus their safety inspection efforts on vehicles and drivers most likely to have safety-related deficiencies. However, half of MVE's 12 roadside scales are not equipped with PrePass technology, so they are not operating with the same efficiency. Plus, none of MVE's mobile patrol operations are able to pre-screen vehicles approaching their temporary safety and weight inspection locations.

Currently, there are nearly 750 PrePass-qualified CMV fleets based in the State of Iowa, accounting for over 14,300 individual vehicles. These operators will be the most direct beneficiaries of MVE's expanded e-screening capability, but a significant number of out of state- registered PrePass-qualified vehicles also use Iowa's Interstate and other main highway corridors and will likewise benefit from the travel time and operating cost savings made possible by this technology. In particular, MVE expects to frequently deploy its new mobile PrePass unit in the I- 80 corridor in eastern Iowa, from Davenport to Iowa City, because there is no fixed-site weigh scale facility to monitor the growing CMV traffic in-bound from Illinois.

Transportation System Management Technology to be Included in Project

This project will deploy advanced V2I technology to allow Iowa MVE to expedite and expand its motor vehicle safety and weight enforcement and inspection capabilities in the I-35 and I-80 corridors, as well as in several other Interstate and high truck volume corridors. The project features several ATMS technology elements, which are described in more detail below.

Virtual Weigh Stations

The Office of MVE will deploy virtual weigh station (VWS) technology in the mainline of two Interstate highway corridors:

- I-35 in the Des Moines Metro area between Ames and Des Moines (Polk and Story Counties)

- I-80 between Iowa City and Davenport (Cedar County)

These VWS installations will identify every passing commercial motor vehicle via ALPR technology for real-time carrier/vehicle credential and safety screening and will use weigh-in-motion (WIM) technology to determine a preliminary estimated weight of vehicles exceeding 10,000-lbs gross vehicle weight (GVW). The general concept of operations for VWS installations and specific concept of operations details for the two proposed VWS corridor locations in Iowa are discussed below.

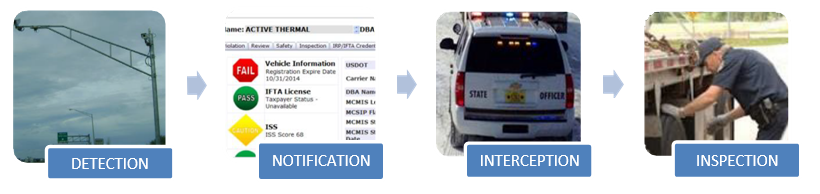

VWS Concept of Operations

The general concept of operations for all VWS field deployments includes four distinct, sequential phases:

- DETECTION –VWS equipment located on/over the highway mainline traffic lanes screens every passing CMV for potential safety or weight violations

- NOTIFICATION – An officer waiting downstream receives vehicle identification and screening information, in real time, in sufficient detail to make an informed (Yes/No) decision on whether to inspect the vehicle for potential safety or weight violations

- INTERCEPTION – The officer maneuvers their vehicle into the traffic stream, intercepts the suspect CMV, and directs the driver to proceed to a suitable pull-off area downstream

- INSPECTION – Axle group weighing and situationally appropriate driver, vehicle or credential inspections are conducted in the pull-off area

Detection

The VWS equipment is strategically located at a position upstream from the officer staging area. The detection equipment includes:

- Weigh-in-motion sensors to measure gross vehicle weight and axle weights

- Conductive loop detectors to measure vehicle length for classification and travel speeds

- Overhead camera with ALPR and optical character recognition (OCR) technology to capture the vehicle license plate

- Overview camera to capture a digital still image of the front/side of the CMV

- Roadside cabinet to house on-site equipment

The VWS system features an automated license plate reader with an infrared (IR) illuminator incorporated to enhance night-time, low light, and inclement weather enforcement operations. In addition, the overview camera to capture still images of the CMV permits officers to view vehicles during low-light conditions.

Several important factors and key assumptions must be considered for locating the VWS equipment, including the following:

- Posted speed limits can vary, which affects the distance a vehicle travels at typical free- flow highway speed, and this travel distance factors into the positioning of downstream staging elements of the VWS system

- The VWS equipment usually only measures vehicles traveling in the right lane, in which case supplemental regulatory signing to direct trucks to use the right lane should be installed upstream of the equipment

- The VWS system should be configured to capture and archive information for any vehicle that measures 10,000-lbs or greater GVW

- Camera features and quality should be sufficient to allow for enforcement operations at night or in hours of diminished daylight

- A smooth pavement and flat approach is required for WIM sensor installation, ideally in concrete pavement where possible

- A reliable, continuous electrical supply is needed to ensure the detection equipment is operational

Notification

The officer will stage in a pre-determined safe location to monitor the VWS screening data and to visually identify a suspected unsafe/overweight truck. VWS selection software will assist the officer in making informed (Yes/No) inspection decisions by alerting when an approaching vehicle exceeds preset thresholds for weight and/or credentials.

Proposed officer staging locations are identified based on the time-lapse typically required for the equipment to detect a CMV, process the data, and transmit the results to the officer's laptop. In addition, the location selection process takes into account the perception-reaction time necessary for the officer to decide which vehicle to inspect and to then visually locate the subject vehicle; for freeways posted at 70 mph, this time is typically estimated to be 30 seconds. [Example: For a vehicle traveling 75 MPH, the distance traveled in 30 seconds equals 3,300 feet.] VWS deployment experience in other states has indicated that to provide an enforcement officer sufficient time to make the decision to intercept a potential violator, a time latency goal of less than five seconds should be established (i.e. the time lapse from sensor reading to laptop recognition).

Officer safety is a major consideration for VWS field operations. For freeway deployments, it is assumed the enforcement vehicle will be idling roadside and pulling into traffic from an interchange entrance ramp. This provides opportunity for officers to stage off the mainline, yet have adequate distance within which to easily achieve freeway speeds as they enter the traffic stream. In addition, an adequate line of sight for the officer is critically important for visually identifying the approaching subject vehicle.

Iowa MVE officers currently utilize 360 SmartView® software at two fixed weigh stations and on their laptops for patrol operations. This software application is used to assist officers with querying various relevant motor carrier data sources and making an informed decision to select a subject vehicle for inspection. Experience in VWS deployments in other states indicates a key success factor is to use the same operating system throughout the state. Since officers operating

fixed-site weigh stations are typically also tasked with conducting VWS operations in nearby highway corridors, maintaining consistent software and vehicle credential selection criteria aids officer familiarity in operating the system. Therefore, the proposed roadside technology for the VWS system will be integrated with MVE's existing software application.

Suspect vehicle selection criteria and thresholds should be easily configurable by officers for immediate implementation. This allows officers to focus on one specific element of enforcement (e.g. weight, safety, out-of-service [OOS] orders) for different enforcement periods, if desired. Selection criteria to consider may include:

|

|

|

|

|

|

Interception

The process for intercepting a suspected violator begins with the officer being logged into the VWS screening software and staged in an appropriate location to identify the subject vehicle. The sequence includes:

- Officer visually identifies vehicle for inspection

- Officer pulls into traffic from staging area

- Officer pursues and intercepts vehicle on the freeway shoulder

- Officer directs operator to proceed to designated pull-off area

- Officer follows suspect vehicle to rest area

In VWS system operations it is important to account for the distance a suspected violator will travel through these five steps of interception. Based on VWS experience in other states, a conservative estimate is it may take least two miles of travel distance for an officer to pull into a live traffic stream, overtake the suspect vehicle, and get their attention to slow and pull over onto the right shoulder of the roadway. Officer staging on an entrance ramp will assist with the enforcement vehicle reaching freeway travel speeds and entering live traffic.

Important factors and key assumptions that should be considered for locating the interception zones in a VWS deployment include the following:

- Roadway cross-sections can vary, especially the width of the paved shoulder area. A paved surface at least 10-ft in width should be adequate width for temporarily stopping a CMV, allowing the officer to approach the vehicle from the passenger side to direct the driver to proceed to a pull-off area downstream at a rest area or designated trucking parking site.

- Informational roadside signing can be useful to alert CMV operators to be vigilant for MVE vehicles attempting to engage them and, when directed, to safely move to the right shoulder and stop.

- Due to the high volumes of traffic on freeway corridors near large urban areas, there will be certain time periods during which active VWS-based enforcement should be avoided due to potential adverse effects it may have on traffic flow, as well as to minimize risk to officer safety. Specifically, a dual lane freeway may operate well above a lane capacity of 1,800 vehicles per hour (vph). Assuming that some passing vehicles will continue to use the right lane during an officer's interception stop of a large truck on the right shoulder – despite the state's "Move Over" law – a dual lane volume of 2,000 vehicles per hour is a conservative threshold above which VWS-based enforcement activities should be avoided.

Inspection

Upon arrival in the rest area, the subject vehicle proceeds to the designated pull-off area, where officers conduct axle group weighing (using portable wheel weighers) and/or the appropriate- level inspection of driver, vehicle and/or credentials.

Important factors and key assumptions that should be considered for locating the inspection areas in a VWS deployment include the following:

- Geometrics of access/egress points should be adequate to allow large truck configurations to easily maneuver into, through and from the pull-off area.

- There should be adequate truck parking space for vehicles and drivers placed out-of- service based on inspection results.

- The pavement should be sufficiently flat/level and well-drained to facilitate the use of calibrated portable wheel weighers and, if deemed operationally appropriate, for under- vehicle portions of NAS Level I inspections.

VWS Deployment Details: I-35 Des Moines Metro area in Polk and Story Counties

The I-35 corridor in the Des Moines Metro area was chosen for deployment of VWS for five primary reasons:

- The I-35 SB Story fixed scale location is being decommissioned due to age

- Truck volumes (18% of all traffic, or 8,200 trucks per day) on I-35 are high enough to justify enforcement activities during non-peak hours

- The I-35 corridor has been identified as a high truck crash corridor

- The I-35 is identified on the FHWA National Freight Network

- The new rest area facility on I-35 NB can accommodate CMV inspections and truck parking.

Figure 3 shows potential locations on I-35 in the Des Moines Metro area for VWS detection equipment, officer staging, interception zones, and inspection areas.

Figure 3 - VWS Operational Map, I-35 Northbound and Southbound (Des Moines Metro Area)

There are several reasons the I-35 rest areas are suitable locations to conduct inspections. The Iowa DOT has a project currently programmed to construct dedicated inspection space within the rest areas for MVE officer use. Using this rest area affords several additional advantages for MVE officers, including:

- Interior office space is available, as needed, for officers to utilize before, during or after their inspections

- Technology may be installed by Iowa DOT to facilitate the automatic download of dashboard camera video to make more efficient use of officer time spent at the rest area

- Suitable, safe and secure location to place a driver and/or vehicle out-of-service

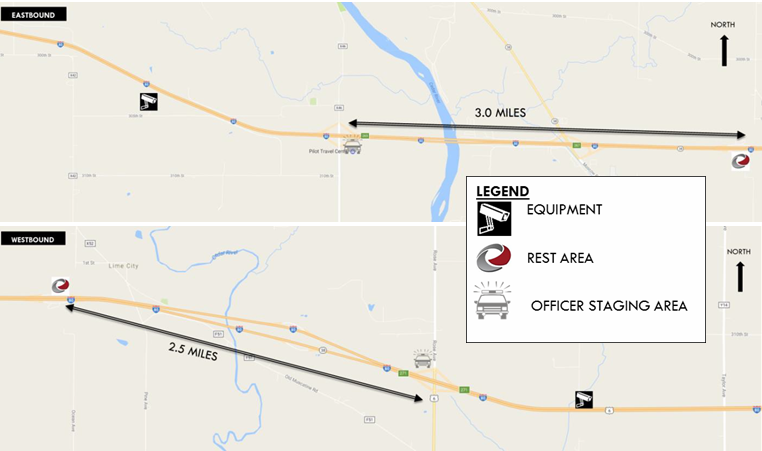

VWS Deployment Details: I-80 between Iowa City and Davenport in Cedar County

The I-80 corridor between Iowa City and Davenport was chosen for deployment of VWS for five primary reasons:

- Enhanced enforcement is needed for CMVs entering Iowa from Illinois with destination cities other than Des Moines that are not screened at the fixed scale in Jasper County

- Truck volumes (35% of all traffic, or 11,900 trucks per day) on I-80 are high enough to justify enforcement activities during non-peak hours

- The I-80 corridor has been identified as a high truck crash corridor

- The I-80 is identified on the FHWA National Freight Network

- The existing rest area facilities on I-80 EB and WB can accommodate CMV inspections and truck parking

Figure 4 shows potential locations on I-80 between Iowa City and Davenport for VWS detection equipment, officer staging, interception zones, and inspection areas.

Figure 4 - VWS Operational Map, I-80 Eastbound and Westbound (Iowa City to Davenport)

There are two former MVE safety and weight enforcement stations on I-80 (both EB and WB) in Cedar County near Mile Post 269 that have been decommissioned (i.e. the buildings and platform scales have been removed). However, the entrance/exit ramps and paved surfaces have been retained and are kept open 24/7 for use by CMV operators as short-term public parking areas. These sites are suitable for use as pull-off areas for VWS-based inspections since they have adequate geometrics for easy access, offer level/paved surfaces for MVE officers to deploy their portable scales, and provide space for parking CMVs ordered out-of-service.

Fixed Scale Enhanced Electronic Screening

The Office of MVE will deploy Enhanced Electronic Screening (e-Screening) assemblies on ramps approaching eight existing fixed roadside safety and weight enforcement scales, including:

- I-35 NB in Clarke County (between the Missouri state line and Des Moines)

- I-29 NB in Fremont County (between the Missouri state line and Council Bluffs)

- I-380 NB (near Brandon, IA) in Buchanan County (between Waterloo and Cedar Rapids)

- I-380 SB (near Brandon, IA) in Buchanan County (between Waterloo and Cedar Rapids)

- I-80 WB (near Avoca, IA) in Pottawattamie County (between Des Moines and Council Bluffs)

- I-29 SB (near Salix, IA) in Woodbury County (between Sioux City and Council Bluffs)

- I-35 SB in Worth County (between the Minnesota state line and Des Moines)

- US 218 NB (near West Point, IA) in Lee County (between the Illinois state line and Iowa City)

Figure 5 - Fixed Scale Enhanced Electronic Screening Map

These Enhanced e-Screening installations will identify every passing CMV using ALPR and USDOT number reader technology for real-time carrier/vehicle credential and safety screening utilizing 360 SmartView® software, which is a cloud-based truck sorting system for roadside and mobile enforcement that provides officers with an automatic, single-screen view of each vehicle's safety and compliance status.

Table 2 provides historical information for the operations for each of the eight fixed weigh stations. This enhanced e-screening concept will impact the weigh stations which are open for approximately 10,000 hours per year and weighs almost 300,000 trucks, resulting in over 33,000 inspections performed at these fixed facilities. This technology will enable officers to make inspection selection decisions based on a "360-view" of each vehicle.

Scale Locations |

Days Open |

Hours Open |

Trucks Weighed |

# Inspections |

|---|---|---|---|---|

#10 Clarke NB |

163 |

941 |

27,314 |

2,542 |

#14 Fremont NB |

166 |

1,051 |

21,429 |

1,690 |

#15 Brandon NB |

155 |

1,035 |

35,196 |

5,303 |

#16 Brandon SB |

162 |

1,040 |

36,232 |

5,442 |

#28 Avoca WB |

221 |

1,605 |

59,605 |

3,728 |

#37 Salix SB |

224 |

1,739 |

55,862 |

6,118 |

#39 Worth SB |

206 |

1,307 |

34,178 |

4,462 |

#45 West Point NB |

199 |

1,345 |

17,671 |

3,839 |

Annual Totals |

1,496 |

10,063 |

287,487 |

33,124 |

The general concept of operations for Enhanced e-Screening and specific concept of operations details for the eight proposed locations in Iowa are discussed below.

Fixed Scale Enhanced e-Screening Concept of Operations

The proposed Enhanced e-Screening concept of operations provides for mainline CMV screening for both active enforcement and passive data collection purposes. The system is designed to allow MVE officers to better identify vehicles that should be stopped for inspection. The proposed Enhanced e-Screening concept of operations is organized into three distinct stages (described in more detail below), including:

- DETECTION – ALPR and USDOT number reader equipment located in advance of the scale for identifying vehicle attributes

- NOTIFICATION – The officer receives vehicle information sufficient to make an informed (Yes/No) decision on inspection

- INSPECTION – Axle group weighing and appropriate-level driver, vehicle or credential inspection conducted at the scale

Detection

Figure 6 - Example Assembly with License Plate Reader, USDOT Number Reader, and Overview Camera (Jasper County, IA)

The Enhanced e-Screening equipment is strategically located at a position upstream from the scale. The equipment includes:

- Overhead camera with automated license plate reader (ALPR) and optical character recognition (OCR) technology to capture vehicle license plate

- Side-mounted USDOT number reader and OCR technology to capture the door-mounted USDOT number

- Overview camera to capture a digital still image of the front/side of the CMV

- Roadside cabinet to house on-site equipment

- Breakaway aluminum pole

The overview camera is used to capture still images of the CMV and should permit officers to view and identify vehicles during low-light conditions.

Each of the eight sites has similar ramp configurations and scale building size. Figure 7 shows an example deployment layout at the I-380 SB Brandon fixed scale.

Figure 7 - Enhanced E-Screening Site Layout (I-380 SB, near Brandon, IA in buchanan County)

There are several important factors and key assumptions that must be considered for locating the Enhanced E-Screening equipment. Some general considerations for equipment location are featured below, and Table 3 identifies site-specific features or characteristics to consider.

- Equipment assembly will be located on the ramp entering the facility – not on the mainline

- Posted speed limit for the scale entrance ramp should be 30 mph

- Supplemental regulatory signing to direct trucks to use the right lane of the scale entrance ramp should be installed in advance of the equipment assembly since the readers will only scan vehicles in a single lane

- The system should capture and archive information for any vehicle that has a suspected violation

- Camera features and quality should allow for night-time/low-light enforcement operations.

- The pole for the equipment assembly should be mounted on a breakaway base

- An adequate clear zone should be provided from the edge of pavement, or if an adequate clear zone distance is not feasible then cable rail or guard rail should be installed to protect the equipment

|

||

Relevant Factors to Consider |

|

|

Notification

The Enhanced E-Screening software interface will assist the officer in making informed inspection (Yes/No) decisions by alerting when an approaching CMV exceeds preset thresholds for credentials.

Entrance ramp assembly locations will be identified after considering the time-lapse needed for the equipment to detect a CMV, process the data, and transmit the results to the viewing monitor. Experience in other states has indicated that a time latency goal of less than five seconds should be established (i.e. the time lapse from sensor reading to laptop recognition).

A software application will be required to assist MVE officers with querying various relevant CMV and motor carrier data sources and making an informed credential-based decision to select a subject vehicle for inspection. The 360 SmartView® software that Iowa MVE will procure in a separate project to enhance MVE screening operations at the Dallas and Jasper County weigh stations on I-80 near Des Moines will also be considered for use in these eight Enhanced e- Screening installations. Experience in other states indicates a key success factor is to use the same operating system throughout the state.

The credential-based selection criteria and thresholds will be easily configurable by MVE officers for immediate implementation. This will allow officers to focus on one specific element of CMV enforcement (e.g. weight, safety, OOS orders, etc.) for different enforcement periods, if desired. Selection criteria to consider may include:

|

|

|

|

|

|

Inspection

Upon entering the facility, each CMV will proceed to the platform scale, where MVE officers will conduct routine axle group weighing. If any issues are flagged within the system, an appropriate- level inspection of driver, vehicle and/or credentials will occur. MVE officers may instruct a CMV operator to park in the designated truck parking area for the inspection to be conducted. This ensures that the platform scale is always available for trucks to be weighed when the facility is open.

Long-Term Operation and Maintenance

Table 5 shows potential operational schedules for MVE officers working the proposed I-35 and I- 80 VWS installations. Certain assumptions were made in developing this schedule, including:

- Two officers per shift, working a 3-hour shift

- 144 officer hours available per month

- Balance the shifts on Monday-Thursday, with limited enforcement operations conducted on Fridays, Saturdays, and Sundays

- Based on current MVE schedule rotation, approximately 60% of the shifts begin at 6 AM, 20% begin at 10 AM, 16% begin at 2 PM, and 4% begin at 8 PM

- Account for recommended enforcement time restrictions on I-35; the I-80 corridor does not have restricted enforcement times because of lower traffic volumes

Based on the VWS concept of operations described above for screening the vehicle, intercepting the vehicle, conducting the inspection, and then re-positioning the officer back to the Interstate, it is feasible to conduct one inspection per officer hour worked. The time interval details are summarized in Table 4 below. Sample enforcement schedules for I-35 and I-80 VWS-based operations are shown in Table 5.

| Phase | Duration |

Notes |

|---|---|---|

Interception |

10 |

Calculated time from officer recognition to escorting the vehicle to the rest area is 5 minutes. This was rounded up to 10 minutes for a conservative estimate. |

Inspection |

40 |

Weighted average based on the duration of the inspections conducted (from TraCS) by level and the percentage split of inspection levels conducted. Calculated time = 36.5 minutes. |

Re-position |

10 |

Approximate time for an officer to relocate to the staging location and log back into the VWS system. |

Total Time Per Inspection |

60 |

Inspections to be conducted based on the sample enforcement schedule shown in Table 5. |

I-35(WEEK 1) |

I-35 (WEEK 2) |

|||||||

|---|---|---|---|---|---|---|---|---|

|

AM Peak |

Mid-Day |

PM Peak |

Overnight |

AM Peak |

Mid-Day |

PM Peak |

Overnight |

SUN |

SB |

|||||||

MON |

NB |

SB |

NB |

|||||

TUES |

SB |

NB |

SB |

|||||

WED |

SB |

|||||||

THUR |

NB |

SB |

||||||

FRI |

NB |

|||||||

SAT |

NB |

|||||||

I-80 (Week 1) |

I-80 (Week 2) |

|||||||

|---|---|---|---|---|---|---|---|---|

AM Peak |

Mid-Day |

PM Peak |

Overnight |

AM Peak |

Mid-Day |

PM Peak |

Overnight |

|

SUN |

EB |

|||||||

MON |

WB |

EB |

||||||

TUES |

WB |

EB |

||||||

WED |

WB |

WB |

||||||

THUR |

EB |

WB |

||||||

FRI |

EB |

WB |

||||||

SAT |

EB |

|||||||

NO ENFORCEMENT RECOMMENDED (NB and SB)

Operational efficiency is improved by building and maintaining strong in-house maintenance and repair capabilities. A competent preventive maintenance program allows MVE officers to work more efficiently by relying on the technology to help make informed inspection decisions. Both MVE personnel and CMV drivers have increased confidence levels when equipment and systems are functional and accurate. To avoid prolonged system downtime and higher operational costs, Iowa DOT routinely performs in-house preventive maintenance and repairs that not only keep system downtime to a minimum, but also reduce associated costs. The agency has sufficient qualified staff on-site with the appropriate resources and expertise to complete most routine maintenance and repair tasks. However, Iowa DOT also relies on contractors to keep high tech equipment in good operating condition and to perform required maintenance. Software maintenance includes error correction, enhancements of capabilities, deletion of obsolete capabilities, and optimization.

Iowa DOT utilizes a hosted service for ITS maintenance, known as ITS OnRamp, to monitor the operation of all ITS devices. ITS OnRamp is a monitoring tool that assists with tracking response and repair timeframes and with organizing maintenance records. When a repair is needed, the Iowa Traffic Management Center (TMC) is called and a ticket (or service order) is created in ITS OnRamp to initiate the repair and to track the response through to completion. Typically repairs are completed within 48 hours. In addition, system performance and ITS devices and systems throughout Iowa DOT's jurisdiction are monitored by IP Monitor. If an issue occurs, IP Monitor alerts and notifies the correct internal Iowa DOT help center. This is the maintenance procedure that is in place after the initial system warranty and maintenance plan expires.

Potential Challenges to Deployment

There are no known existing or anticipated regulatory, legislative or institutional challenges or obstacles to the deployment of the project elements.

Expected System Performance Improvements

This V2I technology deployment project is expected to increase the efficiency and effectiveness of Iowa DOT efforts to detect and deter illegally overweight and unsafe trucks in the I-35 and I-80 corridors and in other high truck volume corridors. Expected system performance improvement benefits will include:

- Improved operational efficiency of personnel assigned to the VWS installations on I-35 and I-80 due to more targeted attention to illegally overweight and potentially unsafe trucks

- Improved operational efficiency and mobility of truck movements throughout the I-35 and I-80 corridors, and other high truck volume corridors, across Iowa.

- Reduced crashes associated with heavy trucks

- Improved pavement preservation with enhanced truck size and weight compliance

Expected Safety, Mobility and Environmental Benefits

This project is expected to increase public safety and security and to improve the operational efficiency of heavy trucks operating in the I-35 and I-80 corridors and other high truck volume corridors. Expected benefits will include:

- Fewer and less severe traffic crashes involving commercial motor vehicles; reduced loss of cargo and reduced equipment damage for CMV fleet operators

- Improved operational efficiency and mobility of safe and legal weight trucks operating throughout the Primary Highway corridors across Iowa

- Hours of time saved by truck drivers through enhanced screening

- Fuel saved with the improved mobility

- Operational costs savings by the Iowa DOT MVE

- Reduced emissions by CMVs with the increase in mobility efficiency

Vision, Goals and Objectives / Future Related Deployments

With the projected increase in truck-borne freight in the future, the Iowa DOT MVE's program vision is to operate more efficiently and to continue to provide a successful truck enforcement program that promotes compliance from carriers and drivers. Deploying new technology to assist officers with making data-driven decisions is a specific goal for the Iowa DOT. The deployment of new technology on two critical freight corridors, I-35 and I-80, along with the integration of e-screening software at numerous safety and weight enforcement facilities, will assist the Iowa DOT in meeting this goal.

Iowa DOT has a number of on-going initiatives related to traffic operations, freight management, safety improvements, and commercial motor vehicle enforcement. What follows is a summary of some of the initiatives and how they relate to and impact this ATCMTD grant funding request.

- In January 2016, Iowa DOT completed a Transportation Systems Management and Operations (TSMO) Strategic Plan and a TSMO Program Plan. The TSMO initiative improves the agency's ability to proactively manage the transportation system by addressing recurring and non-recurring congestion in real time. TSMO strategies, such as traffic incident management, traveler information services, safety service patrols, work zone management and freight management, improve system efficiency, enhance public safety, help reduce traveler delays, and improve information access. MVE's CMV enforcement operations, especially in the I-35 and I-80 corridors, are a critical element of Iowa's TSMO Plan. The ATCMTD funding being requested will enable MVE to help the agency meet the goals and objectives identified in the TSMO Plan.

- The Iowa Strategic Highway Safety Plan (SHSP) was created to identify at-risk facilities and to implement effective strategies to inform customers and provide safer roads to reduce fatalities and major injuries. Iowa DOT is dedicated to implementing the SHSP through a data-driven, innovative, and proactive planning process that addresses the "4E's" of roadway safety (i.e. engineering, education, enforcement, and emergency medical services). Two of the three priority strategies related to technology articulated in the SHSP (as shown on the right) are related to enforcement and are directly relevant to this ATCMTD funding request

- The Iowa State Freight Plan connects Iowa DOT's various freight planning initiatives, allowing them to move forward toward the common goal of optimizing freight transportation in the State of Iowa. One strategy articulated in the Plan is to use advanced technology, performance management, innovation, competition, and accountability in operating and maintaining Iowa's freight transportation system, which directly aligns with this ATCMTD funding request.

- Iowa DOT completed a statewide Interstate Corridor Plan in 2013 and is currently undertaking a more specific I-80 Planning Study. The I-80 corridor study area includes highway segments that will be served by the VWS installations between Iowa City and Davenport. MVE will coordinate the ATCMTD-funded technology enhancements on I-80 in eastern Iowa throughout this corridor-specific planning process.

- MVE will continue to develop and follow the agency's federally-required annual MCSAP Commercial Vehicle Safety Plan and FHWA Vehicle Size and Weight Enforcement Plan. Iowa DOT is committed to meeting the goals identified in those plans. The ATCMTD-funded technology will help MVE meet the annual goals articulated in those plans and will also provide opportunities to improve on their goals in future years.

- Two additional CMV enforcement initiatives in which MVE actively participates are the FMCSA-sponsored Innovative Technology Deployment program (formerly known as the "Commercial Vehicle Information Systems and Network" [CVISN] Program) and Performance and Registration Information Systems Management (PRISM) Program. Iowa is Expanded ITD- compliant and is also a leading state in the PRISM Program, having reached the final step in the PRISM process along with 25 other states and the District of Columbia. The enhanced enforcement technology elements that will be acquired with the requested ATCMTD funding will enable Iowa DOT to continue to meet and exceed these FMCSA program requirements.

Internal and External Partnerships

Iowa DOT will coordinate with FHWA and FMCSA for technical assistance and guidance in the design and implementation of this project. Iowa DOT will actively partner in this project with HELP, Inc., which is the Nation's oldest, non-profit, private-public partnership dedicated to advancing the safety and efficiency of the motor carrier industry.

As appropriate, advice and counsel will be sought from several external Iowa-based potentially- affected interests, including the Iowa Department of Public Safety (i.e. the Iowa State Patrol and the Governor's Traffic Safety Bureau), the Iowa Homeland Security and Emergency Management Department (HSEMD), and the Iowa Freight Advisory Council, which includes representation by the Iowa Motor Truck Association.

The Iowa DOT has successfully fostered internal partnerships to provide a more efficient transportation system. Several ways in which the Office of Motor Vehicle Enforcement has participated in these partnerships include:

- Sharing WIM data with the Office of Systems Planning, including the coordination of new WIM sites in desirable locations for enforcement purposes

- Incorporation of weigh station equipment into the ITS maintenance contract managed by the Office of Traffic Operations

- Co-location of the Iowa DOT 24/7 Traffic Management Center (TMC) within the MVE headquarters building in Ankeny, IA

- Facility maintenance resources provided by the Office of Maintenance for utilizing the rest area maintenance services for fixed weigh station building maintenance

- Coordination with Highway District 1 on the design and construction of dedicated inspection space within existing rest areas

- Support provided by the Information Technology Division to operate the various communications infrastructure and other computer or network services

Iowa DOT will also partner with neighboring state highway and motor carrier enforcement agencies, private sector technology vendors, national motor carrier associations, the Commercial Vehicle Safety Alliance (a North American international non-profit organization dedicated to promoting motor carrier safety and security), state and national truck driver associations, academic institutions, and other motor carrier safety and infrastructure protection stakeholder groups who are interested in the lessons learned/best practices developed thru MVE's deployment of the technologies being funded with this ATCMTD grant.

Leveraging / Optimizing Existing ITS Investments

In Fall 2016, the Iowa DOT deployed VWS technology at the I-80 Dallas and Jasper County weigh station facilities. This equipment was installed on the weigh station ramps to screen trucks using WIM, ALPR, USDOT number readers, overview camera, and an over-height detection system. Trucks that are flagged are directed to the platform scales and enforcement building while all others are directed to bypass the scales for improved mobility. The equipment is integrated with the 360 SmartView software to provide the officers with the necessary information during their screening process. This technology was successfully deployed as part of an FMCSA PRISM grant and has been in operation for several months.

The Iowa DOT will optimize the equipment utilization through their experience operating the technology in previous or planned deployments. They will leverage this existing ITS investment as a proof of concept for additional deployments throughout the state to improve their system coverage for truck size, weight, and safety enforcement.

Deployment Schedule

Within four weeks following notification of the awarding of ATCMTD grant funding, Iowa DOT will convene a Kick Off meeting with FHWA and FMCSA staff at a mutually agreed upon location. The Office of MVE will submit monthly progress to FHWA, which document activities performed, anticipated activities, and any changes to the schedule or anticipated issues that may inhibit adherence to the project schedule. Beginning one year after full deployment of the project elements, the Office of MVE will submit an annual report to the USDOT Secretary, which describes the deployment and operational costs compared to the estimated benefits and savings and how the project has met the original expectations laid out in the original deployment plan.

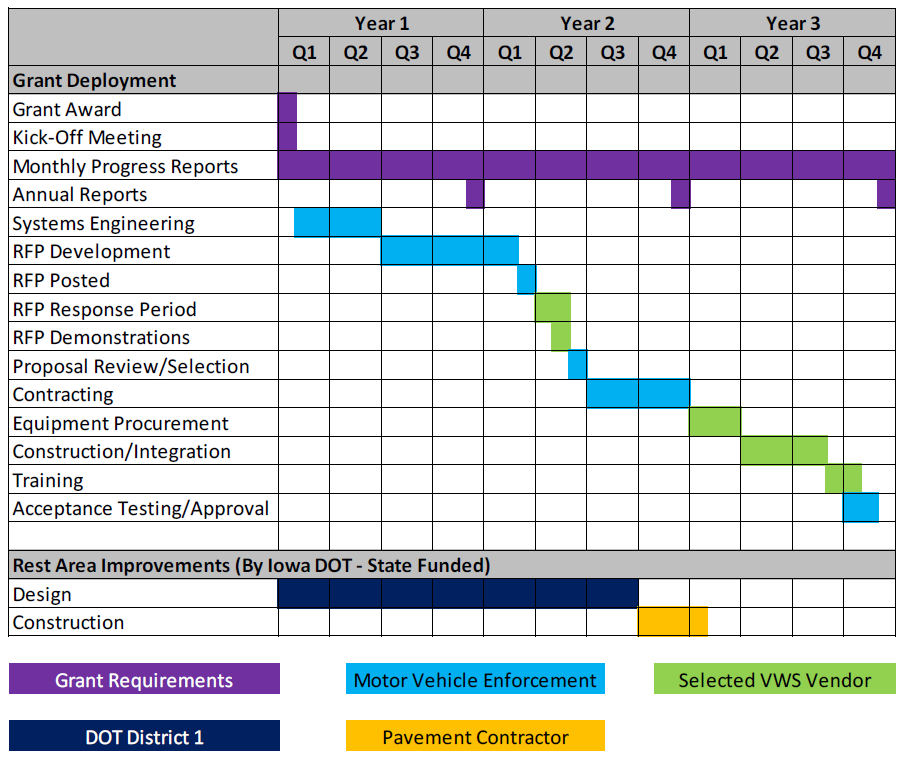

Additional project schedule details are outlined in Figure 8 which shows the planning, design, and procurement process to achieve a functional e-Screening solution.

Figure 8 - Project Schedule

Related ITS Program Initiatives

The Commercial Vehicle Information Systems and Networks (CVISN) Core and Expanded Deployment Program (now called the ITD Program) is listed as a success story on the USDOT ITS Joint Program Office website. The goal of this program is to exchange critical information on safety and credentials of commercial vehicle operations. The deployment of virtual weigh station technology has historically been eligible for CVISN-related grants and is encouraged by the CVISN/ITD program. In 2016 the Iowa DOT became CVISN/ITD Expanded-compliant and the deployment of additional VWS technology was listed within their Expanded Program Plan and Top Level Design as one project to enhance program operations.

This project will also require the Iowa DOT to follow the Systems Engineering documentation requirements of CFR 940. This process will be completed in close coordination with FHWA and the Iowa DOT Office of Traffic Operations. The Systems Engineering analysis will include:

- ITS architecture review

- Stakeholder coordination

- Technical requirements development

- Alternative configuration evaluation

- Procurement options

- Testing and verification procedures

- Concept of operations