Work Zone Safety and Mobility Rule

for Design-Build Projects

Successes, Challenges, and Tips

PDF Version 554KB

You may need the Adobe Acrobat Reader to view this PDF.

Contact Information: WorkZoneFeedback@dot.gov

FHWA-HOP-13-026

March 2013

Key Aspects of the Rule

- Work Zone Assessment and Management Procedures

- Work Zone Data Collection and Analysis

- Training

- Process Review

- Transportation Management Plans (TMPs)

- Plans, Specifications & Estimates that Include the TMP or Provisions for Contractors to Create a TMP

- Pay Item Provisions for Implementing the TMP

- Designated Trained Persons

Introduction

The Work Zone Safety and Mobility Rule, issued by the Federal Highway Administration (FHWA) in 2004, aims to bring about greater consideration and understanding of work zone impacts throughout project development; minimization of those impacts where possible through scheduling, coordination, design, and staging decisions; and better management of remaining impacts during construction. Design-build projects have become more prevalent as agencies seek to speed up projects to leverage resources. The principles advocated by the Rule and its provisions apply to design-build projects, but may need to be applied somewhat differently to address the differences between design-build and traditional design-bid-build.

Research was conducted to explore and identify the issues with and approaches to applying the Rule to design-build projects and how this affects the project development process. In-depth research was done through two case study sites to further examine the issues and identify successes, challenges, and tips. This leaflet summarizes the key points and uses the two case studies to illustrate successes and challenges. More details are provided in the publications referenced at the end of the leaflet. The two case studies are briefly described below.

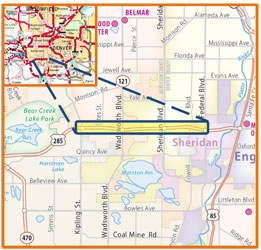

Colorado US 285 Design-Build Project

Colorado Department of Transportation's (CDOT) US 285 Design-Build Project was a $40 million safety and mobility project on US 285 (Hampden Avenue) in the southwestern part of the Denver Metropolitan area. The project covered four miles of a mostly four-lane limited access facility that included one signal controlled intersection. The primary elements of the project were reconstruction/resurfacing of the highway replacement of three bridges, rehabilitation of four bridges, and reconstruction of an interchange.

North Carolina I-85 Corridor Improvement Project

The I-85 Corridor Improvement Project was a $201.5 million design-build project located in Central North Carolina, half way between Charlotte and Greensboro. The project was split into separate north and south segments. Each segment was let as an individual design-build contract, with a different team selected for each segment. The southern segment included the I-85 Bridge over the Yadkin River, the only major vehicular crossing for many miles. The primary elements of the project were widening and reconstruction of the highway, and reconstruction of interchanges, bridges, and rail infrastructure.

Differences between Design-Bid-Build and Design-Build That May Affect Rule Application

Two major differences between the design-bid-build and design-build project delivery methods are who assumes the risk during the project and how the roles and responsibilities are handled. Because of these factors, the key aspects of the Rule may need to be applied to a design-bid-build project differently than they do a design-build project. The table below illustrates the different roles and responsibilities for the Owner/Agency and the Contractor in both project delivery methods.

| Design-Bid-Build Method | Design-Build Method |

|---|---|

| Owner/Agency | |

|

|

| Contractor/Design-Builder | |

|

|

Successes, Challenges, and Tips

RFP Development and Proposal Evaluation

Successes

- CDOT placed safety, quality, and mobility as a priority by including extensive requirements in the RFP for the US 285 project and awarded a significant amount (35 percent) of points for those portions of the proposals.

- NCDOT found that if a project begins with a solid scope that specifies non-negotiable items, performance measures, and timelines, many future concerns/conflicts can be avoided.

- NCDOT noted the importance of being specific about the TMP requirements without being overly prescriptive. This allows the Contractor flexibility to generate and implement innovative ideas to shorten the project schedule, increase safety and mobility, and reduce project costs.

- The I-85 Project RFPs devoted significant score percentages to work zone safety and mobility and encouraged value added elements and innovations. The Contractor responded by including some extra elements that aided in work zone monitoring and traffic management.

- The US 285 RFP required that a maintenance of traffic (MOT) task force be created, with CDOT and Contractor personnel, to ensure the TMP was developed in conformance to the RFP.

Challenges

- The I-85 Project required the Contractors to supply portable dynamic message signs (DMS) that could be controlled remotely by NCDOT traffic management centers. The RFP did not include requirements to ensure the signs were compatible with existing NCDOT systems, resulting in difficulties with communicating and controlling the DMS early in the project.

Tips

- Writing a good RFP is a key part to managing the Agency's risk in a design-build project. The Agency must be clear and firm with their non-negotiables in the RFP to avoid bearing unnecessary risks.

- Agency work zone traffic control staff should be involved in RFP development and proposal evaluation. This will ensure that safety and mobility receive the necessary attention during scoping, in the RFP, and in scoring the proposals.

- Proposal evaluation criteria and scoring should reflect the level of traffic management on the project. The RFP should place safety, mobility, and quality as part of the criteria and scoring to communicate to bidders that these factors are important to the Agency.

- Include RFP provisions to require that traffic management issues be addressed promptly. This is particularly important for design-build projects due to their fast moving nature and payment structure. RFPs can specify a timeframe to address issues before monetary damages will be assessed.

- Project specific guidance should be used in the RFP where the Agency's guidelines and/or procedural requirements are conflicting or vague. It is important that the RFP includes project specific guidance that supersedes general policy and clearly defines requirements (e.g., ensuring communications systems are compatible).

- Innovations can shorten project schedule, increase safety and mobility, and reduce costs. It is important for the Agency to recognize the value of innovation and avoid including overly prescriptive requirements in the RFP in order to encourage innovation.

Design and TMP Development

Successes

- Safety was the #1 priority for the CDOT US 285 Project and the Contractor made that clear by implementing many safety related elements as value-added components that were not required in the RFP.

- NCDOT staff reviewed all TCPs internally (instead of using consultants) for the I-85 project to: (1) ensure the plans met NCDOT standards, requirements, and expectations; and (2) eliminate a potential conflict of interest a consultant may have when reviewing plans on behalf of the Agency.

- The flexibility of the design-build process allowed the US 285 Contractor to tailor project phasing to accommodate the strengths of their construction process. This in turn reduced the duration of lane closures and saved money on mobilization and traffic control operations.

Tips

- Design-build projects enable bidders to propose extra elements that provide benefits (value-added elements). These elements can improve work zone safety and mobility and shorten overall project duration.

- The safety of workers and the traveling public should be a top priority. It is important for both the Agency and the Contractor to recognize this from the beginning and work cooperatively throughout the project.

- Direct involvement by the Agency in reviewing TMPs may be more effective in reflecting Agency needs and expectations. The Agency can benefit from using qualified staff within its organization to ensure all standards, requirements, and Agency goals and expectations are met.

TMP Implementation and Monitoring

Successes

- The US 285 Contractor introduced an innovative strategy to reduce traffic flow conflicts at a ramp merging location. This traffic control modification improved safety and mobility as well as constructability.

- NCDOT monitored the I-85 work zone traffic conditions via closed-circuit television cameras and used portable DMS to alert travelers to work zone conditions and incidents.

- The US 285 Project required the Contractor to provide a courtesy patrol on the corridor during weekday peak hours for incident response, towing, and other motorist assistance. This helped increase Contractor accountability and attention to incident management.

- The US 285 Contractor collected traffic volume data and used the results of capacity analysis for staging decisions in a maintenance of traffic variance situation.

- Availability of pre-construction crash data and data collected during the project allowed NCDOT and the I-85 Contractors to assess how the work zones affected crashes and use this information to remedy conditions that led to crashes.

Challenges

- With the fast moving nature of design-build projects, the Agency may not be aware of issues with TMP implementation or a specific traffic control element and the issues may not be addressed before the work in that area is completed and the work zone changed/removed.

- CDOT staff performed manual data collection to monitor safety and mobility for the US 285 Project, but the information collected was generally not recorded nor distributed to other team members.

- CDOT and the US 285 Contractor had difficulty tracking incidents in the work zone. One likely cause was that the project was under the jurisdiction of five different law enforcement agencies.

- Incident data recorded by the US285 Contractor were not used due to resource limitations and because it was not specified in the RFP.

- The I-85 Project RFPs did not require the Contractors to collect or analyze operational data to manage impacts.

Tips

- Safety and mobility issues need to be identified and addressed quickly. Design-build projects often have many configuration changes, so it can be difficult for drivers to get used to the traffic patterns. Project staff need to be on the lookout for traffic flow issues and address then promptly.

- TMP monitoring needs and responsibilities should be identified upfront, and the Contractor's role included in the RFP. This includes what monitoring will be done, how data will be shared, and what actions will be taken on issues. Management of work zone safety and operational performance and use of performance-based specifications are difficult if appropriate data are not collected.

Quality Management

Successes

- The US 285 Project implemented a unique document control method that reduced potential errors and assured that construction crews were working with the correct and most up-to-date plan set.

- NCDOT required the I-85 Project Contractors to each designate a Quality Control Manager to ensure quality policies were established and followed by the Contractor teams, facilitating NCDOT's quick review of plans.

Challenges

- The US 285 Project Contractor had a difficult time developing a Quality Management Plan (QMP) due to the magnitude and complexity of the project. CDOT worked closely with the Contractor to overcome this challenge by exchanging ideas and identifying CDOT's desired concept for the QMP.

- Establishing scoring criteria and a selection process to ensure the winning team has a qualified designer/traffic engineering firm can be a challenge. It is possible that the winning team has a well-qualified general contractor but the design/traffic firm may not have the same level of qualifications and experience, which could impact the quality of plans.

Tips

- Successful implementation of a QMP is beneficial. Implementation of a QMP leads to mutual understanding in roles and responsibilities and collaboration between the Agency, Designer, and Contractor. This can result in more effective utilization of resources, quality products, and cost savings for both the Agency and the Contractor.

Team Capabilities

Successes

- Each I-85 Project RFP required a Traffic Control Supervisor (TCS) who was knowledgeable on TCP design and application and had full authority on maintenance of traffic. The TCS for one segment had extensive experience in North Carolina and fully understood NCDOT expectations and processes.

Challenges

- NCDOT felt that the Contractor did not fully understand the Rule and NCDOT's work zone policy at the beginning of the project, but once the Contractor realized the benefits of applying them, the response was positive.

- NCDOT needed to educate its own staff on the importance of the Rule and NCDOT's associated policies. They recognized that if personnel did not have this understanding, it hampered NCDOT's ability to develop a good RFP and provide guidance and oversight to the Contractor.

Tips

- A traffic control supervisor (TCS) with knowledge on local requirements is beneficial. A common characteristic of design-build projects is that many of the Contractor's laborers come from out-of-State. Having a designated trained person with experience working in the State is beneficial to understanding Agency expectations and development and implementation of effective traffic plans.

- Contractors need to be familiar with the Rule and the Agency's work zone policies. This is more important in design-build projects because the Contractor bears more responsibilities in work zone management.

- Agency staff needs to have knowledge and recognize the value of the Rule and associated Agency policies. This enables the Agency to convey the key messages to the Contractor, and adequately weight work zone safety and mobility in the proposal evaluation process.

Coordination and Partnership

Successes

- The RFP for the US 285 Project required that a task force be established to ensure coordination with affected agencies. This work built trust between the task force personnel and ensured all stakeholders were part of TMP development.

- The close collaboration among the I-85 Project design-build team members and NCDOT enabled them to quickly identify and address issues. All partners involved in TMP development felt they had ownership in the project.

- Coordination and cooperation between the two I-85 Project segments was beneficial. The results of this cooperation were a less congested, safer work zone and reductions in construction time and cost.

Tips

- Project collaboration and good partnership are important to project efficiency and success. This is more important in design-build projects as the Designer, Traffic Engineer, Construction Contractor, and Agency all have to work closely throughout the project. It is essential to make sure all parties are informed.

- Early engagement and participation from stakeholders helps with building goals and expectations into the RFP. This ensures that the Contractor understands the safety and mobility requirements and the Agency's expectations, and incorporates them in design and TMP development.

Additional Resources

Applying the Work Zone Safety and Mobility Rule to Design-Build Projects: Key Considerations

ops.fhwa.dot.gov/wz/resources/publications/fhwahop13023

Applying the Principles of the Work Zone Safety and Mobility Rule to Design-Build Projects: Two Case Studies

ops.fhwa.dot.gov/wz/resources/publications/fhwahop13024

Tips for Incorporating Work Zone Safety and Mobility in the RFP for Design-Build Projects

ops.fhwa.dot.gov/wz/resources/publications/fhwahop13025

Work Zone Safety and Mobility Rule

ops.fhwa.dot.gov/wz/resources/final_rule.htm