Applying the Principles of the Work Zone Rule to Design-Build Projects, Two Case Studies

6. Other NCDOT Design-Build Projects

NCDOT has been using the design-build delivery method since 2001. Initially, the State was limited to letting 25 design-build projects per year, but that restriction was later lifted. NCDOT personnel from several different disciplines indicated that NCDOT has become more comfortable with the process as they have completed more design-build projects. One result is NCDOT's transition from more restrictive specifications for design-build projects to ones that allow for more innovation. Initially NCDOT used fairly prescriptive RFPs for their design-build projects. More recently, NCDOT has used more performance based specifications, allowed flexibility in alternative technical concepts (ATCs), and shifted to more focus on the final product and less on the process.

As part of its experience with design-build, NCDOT highlighted two design-build projects in the Raleigh area, one that had recently been completed project and one that was upcoming. The I-40 Widening Design-Build Project was a $49 million project that included the following improvements:

- Expanding from four lanes to six lanes, including the widening of two structures to accommodate future expansion to eight lanes.

- Providing 12' shoulders.

- Adding a permanent dynamic message sign (DMS).

- Adding new signs on the nearby I-440 to reflect modified route designations.

The future I-40/I-440 design-build project south of Raleigh was planned to include:

- Reconstruction of 11 miles of roadway.

- Bridge rehabilitation.

- Addition of some auxiliary lanes between interchanges.

- Traffic management related elements:

- Accelerating $700,000 of ITS (35-40 devices, including CCTV cameras and DMS) so that it could be used to manage traffic and provide traveler information during construction.

- Adding two dedicated positions at the Traffic Management Center (TMC).

- Liquidated damages if the Contractor does not have the DMS in place, operating and communicating prior to construction or at any time during the project.

Application of the Rule to other NCDOT Design-Build Projects

During the site visit for this case study, the NCDOT WZTC Team also discussed NCDOT's experience on applying the Rule to these other design-build projects. Much of the discussion focused on the recently completed I-40 Widening Project. This section summarizes the discussion on some of the key aspects of the Rule.

Key Aspect #2 - Work Zone Data Collection and Analysis

There was a valuable example of collecting data in a work zone in the I-40 project. Collection and analysis of work zone data benefitted NCDOT, as it uses the information to train and educate their staff and Contractors. NCDOT took advantage of a gradual triple lane closure the Contractor was installing on the mainline. Per the RFP, the Contractor was allowed to close one lane at 8:00 pm, a second lane at 9:00 pm, and the third lane of a four lane highway at 10:00 pm. NCDOT placed cameras on an overpass above the area where the lane closures were occurring, and were also gathering volume data using the Traffic.com sensors.

During the first hour with one lane closed, there was no major effect to traffic. As the second lane was closed queues began to develop, and by the time the third lane was closed there were major queues occurring back from the closure area. NCDOT then compared the video to the volume data and found that queuing started when traffic volume rose to about 1,500 vehicles per hour per lane (vphpl). NCDOT now uses the information they gathered to educate their personnel about how queues propagate and to give them a feel about what the 1,500 vphpl threshold looks like. The information is also used to assist in training their staff and Contractors about traffic management. NCDOT indicated that the effort cost them about $1,000 and the benefits they have gotten out of the exercise have far exceeded the cost.

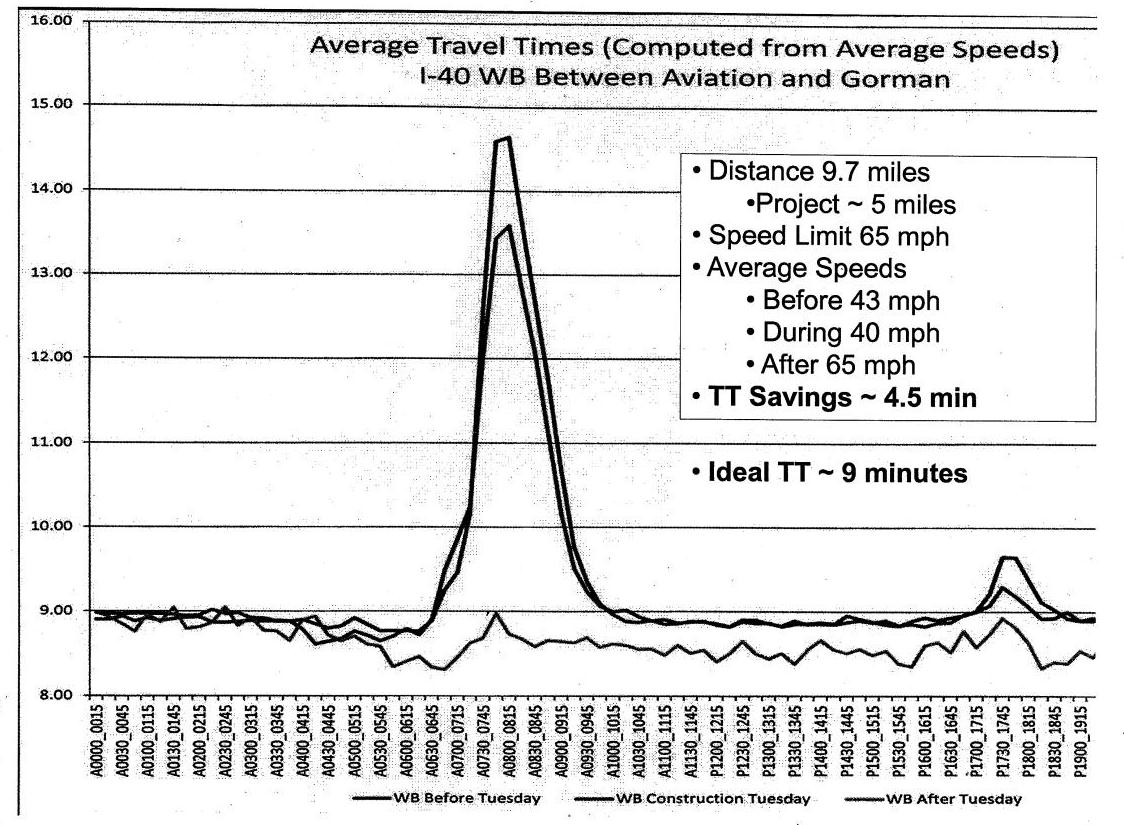

NCDOT collected travel time data before, during, and after the I-40 construction project. The travel time through the corridor was based on average speed data collected at nearly 40 locations. These data for the before, during, and after construction conditions were overlaid in order to show the travel time savings from building the construction project. Figure 6-1 presents an example of this travel time comparison.

Figure 6-1. I-40 Travel Time Comparison

(Source: NCDOT)

Key Aspect #5 - Transportation Management Plan

Discussions with NCDOT and the design-build teams about the differences between design-build and design-bid-build identified several key differences that affect TMP development, which are highlighted in Table 6-1.

| Aspect | Design-Bid-Build | Design-Build |

|---|---|---|

| Plan Development |

The Agency does not know the specific strengths or equipment of the Contractor that will win the job, so plans need to be more general and conservative. A full set of plans is ready before contract award and work can begin as soon as the notice to proceed is given. If the Agency thinks some additional measures are needed in the plans, the Agency as the ability to require the change and pay for it. |

The Contractor knows the strengths and capabilities of its team and equipment, and can develop plans that fit these strengths. TMP developers can create more specific plans for MOT because they better know the needs (e.g., where the Contractor will get its materials from or how wide their paver is). Early in the project, the Contractor may want to work ahead of the plans while they are still under development or review and are not yet released for construction. Some DOTs have allowed elements of the work that do not affect traffic and safety to proceed. More responsibility and liability lie with the Contractor and their team developing the plans, which can be beneficial when the Contractor is thorough about their plans and conscientious about safety. If the Agency thinks additional elements are needed in the plans, the Agency has to convince the Contractor to do it. |

| Plan Review | Detailed reviews of plans by the Agency are needed before bid because if something is missed it could result in an additional cost later. | Details about the plans are developed by the Contractor as the project progresses, so reviews are needed at many points along the way and often in short timeframes. If something was missed by the Contractor in developing the plans, it can usually be added without cost. |

| Plan Changes | One small change to the plans can result in the need to rework other plans and make more changes. | Plans are developed as the project progresses, and there is an effort to look at how everything fits together and an ability to have discussions and make adjustments along the way. Plans may change much more often because the Contractor is suggesting changes to its own plans, which may result in increased need for Agency plan reviews. |

One of the major elements as well as challenges of the I-40 Widening project was the movement of material to and from the widening area (the center of the roadway). NCDOT felt that consistent hauling in and out of the work zone would act almost as a lane closure due to the slow deceleration and acceleration of the haul vehicles. The NCDOT 2006 Standard Specifications Book (the current version at the time of the I-40 project) did not have language on hauling restrictions.

To make sure that the Contractor could not constantly interrupt traffic due to hauling operations, NCDOT included specific hauling restrictions into the RFP. The restrictions dealt with both single vehicle hauling and multiple vehicle hauling operations. Single vehicle hauling is defined as handling of equipment or materials to or from the project with delivery intervals of more than five minutes and resulting in no more than one vehicle in the work site at any given time. Multiple vehicle hauling is stated to be delivery intervals of less than five minutes and/or more than one vehicle in the work zone at a given time. The RFP restricted multiple vehicle hauling during a 15-hour period on weekdays and a 12-hour period on weekends. Single vehicle hauling was restricted during weekday peak periods. An additional clause stated that the hauling vehicles must enter and exit the work area at no less than 10 mph less than the speed limit of the highway they were exiting and entering.

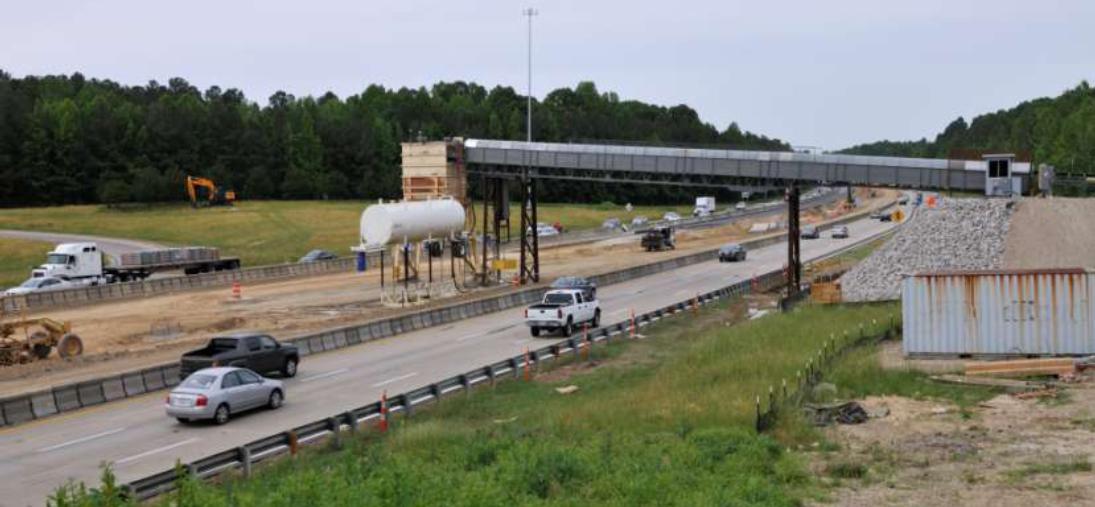

The Contractor felt that they would be far too impacted by the hauling restrictions, and came up with an innovative solution. They used conveyor systems from both sides of the Interstate, over the roadway to move materials to and from the inside where the widening was occurring (see Figure 6-2). The Contractor estimated the use of the conveyors eliminated 237 lane closures and nearly 12,000 truckload trips that otherwise would have been needed to haul materials from the I-40 travel lanes. This is a good example of the benefit of innovation in a design-build project. NCDOT felt that had the project used the design-bid-build delivery method, they would not have been able to specify the conveyor requirement under the standard practices and guidelines used in NCDOT. As a result of the success on this design-build project, the new 2012 version of the NCDOT Standard Specifications now includes a section about single vehicle and multiple vehicle hauling restrictions.

Figure 6-2. I-40 Widening Project Material Conveyor

(Source: S.T. Wooten Corporation)

One other element of the contract was that the Contractor was prohibited from installing barriers more than two weeks in advance of work commencing in a particular area of the work zone. NCDOT was very pleased with the inclusion of this provision and was considering making it part of all projects. Though this requirement would not really differ from design-bid-build to design-build projects, it can improve work zone mobility and the Agency's credibility without compromising safety. Restricting inactive work zones helps with public perception and satisfaction as they do not have to drive through work zones where work is not being performed. Furthermore, when the public has complaints, it is the Agency who is called regardless of who is responsible for traffic control, or what type of project delivery method is being used.

The Contractor also wanted to expand hauling hours on NC 54, a road which passes under I-40. NCDOT required the Contractor to first conduct a traffic study to see if the additional hours would cause unacceptable delays. The Contractor used VISSIM to analyze work zone impacts using Traffic.com sensor data. The study showed that hauling hours could be extended for two hours on weekdays and four hours on Saturday. Based on the study results, NCDOT modified the hours Monday through Thursday, but not on Friday and Saturday. The Contractor used a two-week trial period to determine the impact of the two additional hours in which they could haul, and after the trial period received a $50,000 credit from NCDOT for their effort.

Key Aspect #7 - Pay Item Provisions - Method or Performance Based

The I-40 project experienced some problems with striping and pavement markings. The I-40 RFP included requirements such as a defined level of retro-reflectivity, but it lacked provisions about the quality or durability of the material and installation. The Contractor installed the markings, but during the winter season the striping faded and wore off. At that time of year it was too difficult to restripe due to cold temperatures and the lanes were now all under traffic.

NCDOT did not place any consequences in the RFP for failing to meet the minimum requirements regarding striping and pavement markings. With a design-build contract, because there are not individual pay items the Agency cannot withhold payment for or pay for more units of a given item. NCDOT thought that a solution to this problem would be to use performance-based specifications and attach liquidated damages in the RFP. When monetary consequences are applied to a specific element of the project, there is a greater likelihood that the minimum requirements will be met.

previous | next