| Skip

to content |

|

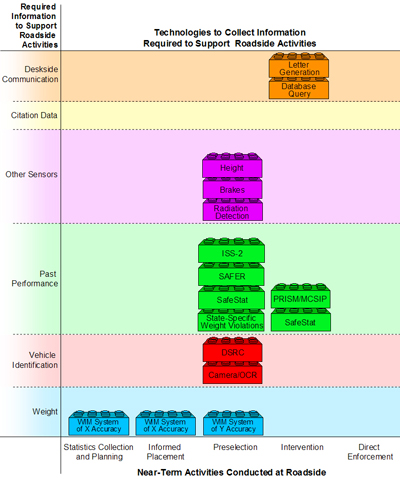

2.0 Overview of Roadside ActivitiesTask 1 of the project produced a diagram that illustrated how roadside technologies could be combined to improve the efficiency and effectiveness of various elements of the roadside enforcement process in the United States. The diagram consisted of two parts. The “Near-Term” activities view depicted technologies currently used by states at the roadside to carry out truck enforcement activities. The “Long-Term” activities view depicted activities and technologies that are planned or could be deployed within the next five to seven years. Because this memorandum addresses the current state of the practice of roadside technologies, consideration will be limited to the near-term activities. The near-term view is shown in Figure 1. This “American Lego diagram” was adapted from the Netherlands and applied to the roadside environment of the United States. Technologies are seen as building blocks that can be added to a truck weight enforcement program to realize greater enforcement efforts using fewer human resources. As building blocks, the technologies can be combined into different solution sets in order to serve multiple purposes at the roadside. The American Lego diagram combines elements of FHWA’s Truck Size and Weight Program with elements of FMCSA’s Commercial Vehicle Information Systems and Networks (CVISN) Program. All acronyms are explained in Appendix A. 2.1 Technology ActivitiesTechnologies are grouped around activities, arranged at the bottom of the diagram. The activities are:

2.2 Focus ActivitiesWeigh-in-motion applications for enforcement are the focus of this memorandum. As Figure 1 shows, WIM is used for statistics collection and planning, informed placement, and preselection activities. WIM is not currently a component of intervention or direct enforcement activities. In preselection, WIM may be combined with vehicle identification technologies, tools to measure past performance, and/or other sensors. WIM scales measure approximate axle weights as a vehicle moves across sensors or scales and determine the gross vehicle weight and classification based on the axle weights and spacings. WIM systems have been used for commercial vehicle operations in the United States for many years. According to Bergan, Berthelot, and Taylor (A.T. Bergan, C.F. Berthelot, and B. Taylor, Effect of Weigh In Motion Accuracy on Weight Enforcement Efficiency, www.irdinc.com/library/pdf/effect_of_wim.pdf, n.d.), WIM is commonly deployed at weight enforcement facilities where static scales cannot handle truck traffic volumes. Traditionally, WIM has been used as a weight enforcement tool to sort trucks either on the approach ramp to a weigh station or on the mainline about a mile upstream of a weigh station. “Mainline WIM sorters are employed when land requirements for a ramp sorter are not available or when truck traffic volumes are too high to safely call in all trucks for ramp sorting,” they maintain. Mainline WIM uses variable message signs to call in trucks suspected of exceeding maximum allowable weight limits, which are directed to the static scale for compliance weighing. Bergan et al. assert that WIM virtually eliminates the unnecessary static weighing of trucks known to be within legal limits and “greatly improves the efficiency and effectiveness of weight enforcement facilities and minimizes delays imposed on the trucking industry.” They add that the accuracy and reliability of the WIM system determines how much unnecessary static weighing of legal trucks is eliminated. Note that the range in accuracy, reliability, and cost of the various WIM technologies is beyond the scope of this memorandum and this project. Figure 1. Technologies to Enhance the Efficiency and Effectiveness of RoadsideEnforcement – Near-Term

Figure 1 - graphic - Technologies currently used by states at the roadside to carry out truck enforcement activities. Technologies are shown as building blocks or legos that can be combined into different sets to serve multiple purposes at the roadside.

WIM also has been widely used in highway traffic monitoring to support pavement research, facility design, infrastructure maintenance, infrastructure planning, and evaluation of congestion trends. To support monitoring of the full traffic flow, WIM devices are installed in the pavement and connected to data collection instruments. The data are sent to various program areas and agencies to support their needs for highway weight-based information. More recently, WIM systems have been deployed to support real-time screening activities at locations that are unstaffed and away from weigh stations. The Technology Implementation Group (TIG) of the American Association of State Highway Transportation Officials (AASHTO) selected “virtual weigh-in-motion (VWIM) as a focus technology because several States sparked a non-traditional use: wirelessly linking WIM information to a highway patrol officer’s laptop in his or her vehicle. The application of ‘virtual technologies’ demonstrates an innovative approach to solving size and weight enforcement issues that ranges beyond the WIM traditional role in data collection and vehicle classification." (American Association of State Highway Transportation Officials (AASHTO), Virtual Weigh-in-Motion: A “WIM-win” for transportation agencies, http://www.transportation.org/sites/aashtotig/docs/VWIM%20Brochure%20Final%2010-27-06.pdf, October 2006.) Additionally, WIM is a component of many states’ Commercial Vehicle Information Systems and Networks (CVISN) deployments. CVISN is a program of the Federal Motor Carrier Safety Administration (FMCSA). Figure 2 depicts a portion of the American Lego diagram, namely, the statistics collection and planning, informed placement, and preselection activities; and the weight (weigh-in-motion) and vehicle identification (dedicated short range communications and camera/optical character recognition) technologies used in these activities. Programs and systems that utilize the given technology have been added to the table. Traffic monitoring employs WIM for statistics collection and planning purposes, mobile screening uses WIM for preselection, and so on. The complete American Lego diagram, produced as part of Task 1, includes two additional activities: intervention and direct enforcement. Neither of them is pertinent to this discussion. Direct enforcement, specifically, is not a target or a priority of FHWA or State Departments of Transportation (DOTs) or law enforcement agencies at this time. The commercial vehicle enforcement activities in Titles 23 and 49, United States Code (23 USC and 49 USC) are described in this memorandum. Technical evaluations of dedicated short range communications (DSRC) and optical character recognition (OCR) are beyond the project scope. NORPASS and PrePass, which utilize DSRC for automatic vehicle identification (AVI) in their electronic screening services, and USDOT number readers and license plate readers, which rely on OCR to support AVI, will be mentioned only in relation to WIM applications.

| ||||||||||||||||||||||||||||||||||

|

United States Department of Transportation - Federal Highway Administration |

||